Traction transformer for Scott wiring

A traction transformer, single-phase transformer technology, applied in the direction of transformers, fixed transformers, transformer/inductor coils/windings/connections, etc., can solve the problems of large floor space, large power loss, high equipment and engineering costs, etc. The effect of reducing floor space, large traction current and high traffic density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

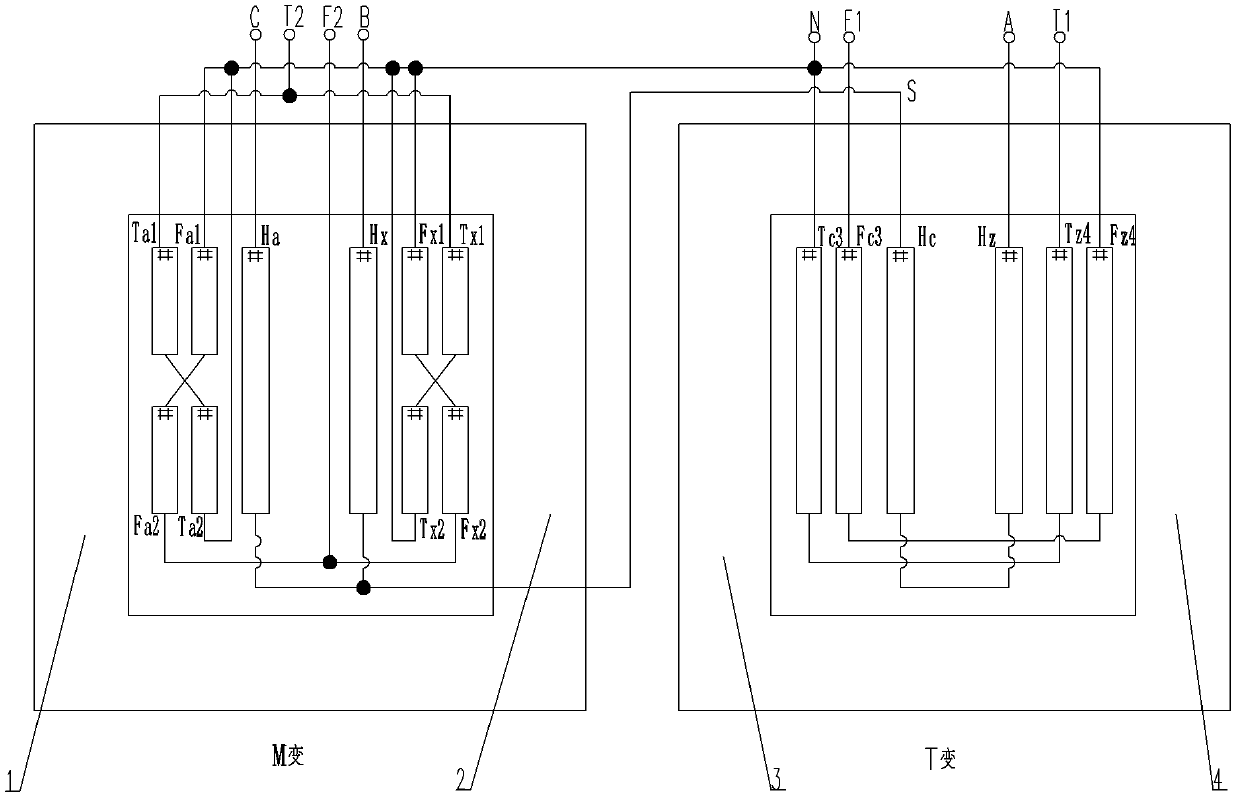

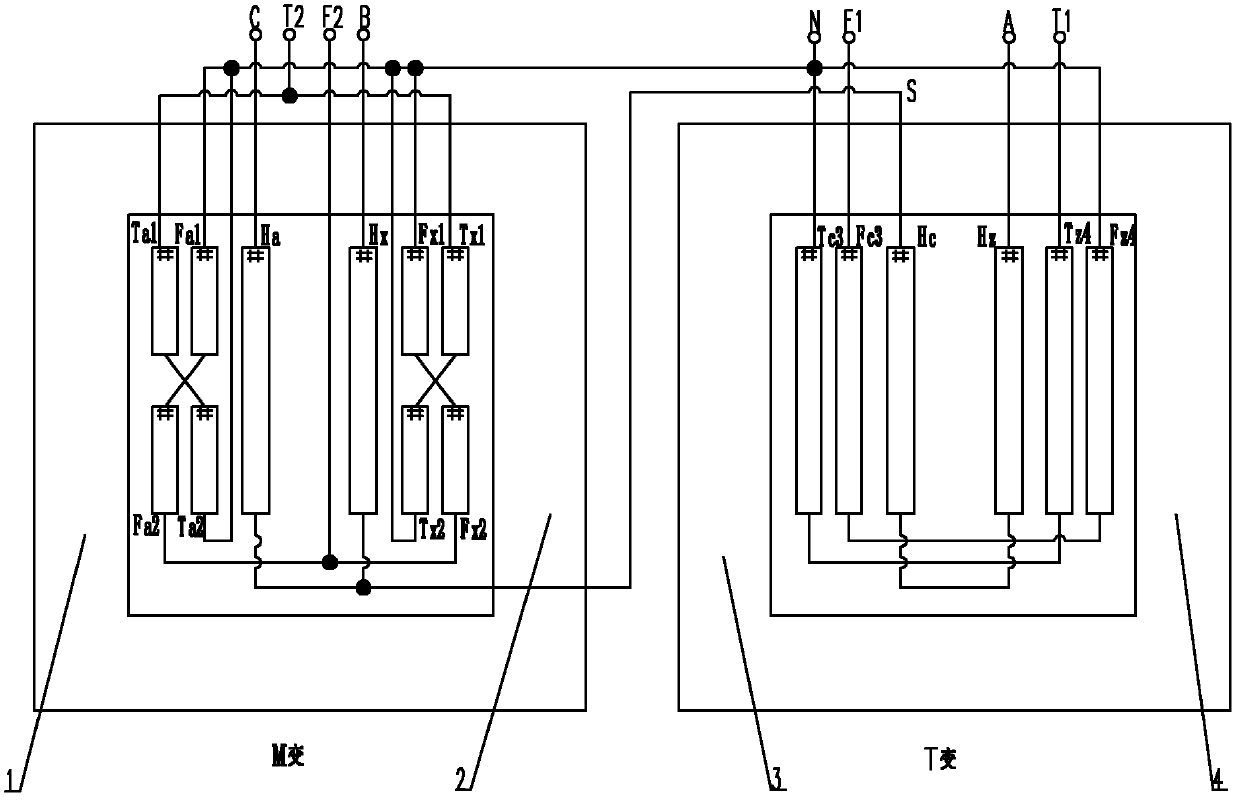

[0013] Embodiment one: if figure 1 As shown, the present invention comprises two single-phase transformers of M change and T change. Column 4, the first main column 1, the second main column 2, the third main column 3 and the fourth main column 4 are connected with three concentric winding layers from inside to outside, which are respectively the first winding layer and the second winding layer and the third winding layer, the third winding layer is the primary side winding H a 、H x 、H c 、H z ; wherein the first winding layer and the second winding layer of the first main column 1 and the second main column 2 are divided into two parts, and the first winding layer includes the first equalized winding T on the power supply side a1 , T x1 And the second equal winding F on the feed side a2 , F x2 , the second winding layer includes the second equal winding T on the power supply side a2 , T x2 and the first equalized winding F on the feed side a1 , F x1 , the first equa...

Embodiment 2

[0015] Embodiment 2: The difference from Embodiment 1 is that the first winding layer and the second winding layer of the first main column 1 and the second main column 2 are divided into upper and lower parts, and the upper half of the first winding layer It is the second equally divided winding F on the feed side a2 , F x2 , the lower part is the first equalized winding T on the power supply side a1 , T x1 ; The upper half of the second winding layer is the second equal winding T on the power supply side a2 , T x2 , the lower part is the first equalized winding F on the feed side a1 , F x1 .

[0016] The input terminals of A, B and C phases of the primary side winding are the input terminals of the three-phase voltage of the transformer 110kV or 220kV; the first output terminal of the power supply side T 1 and the second output T 2 It is the 27.5kV output terminal on the power supply side of the transformer; the first output terminal F on the power supply side 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com