Steel stranded wire bender

A technology of steel strand and bender, applied in the direction of overhead line/cable equipment, etc., can solve the problems of material waste, time-consuming and laborious, and achieve the effect of improving bending quality, ensuring bending accuracy and success rate, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

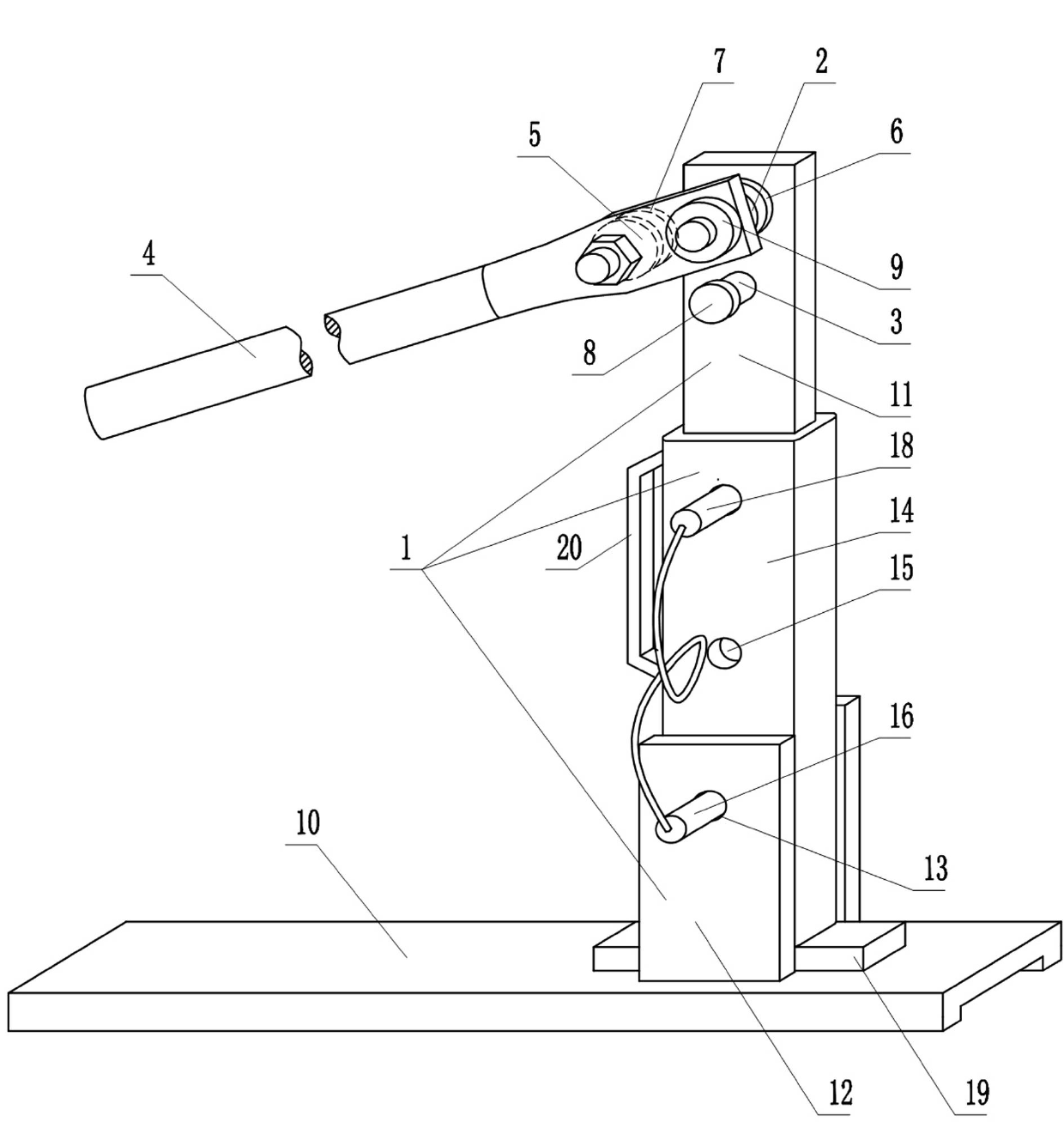

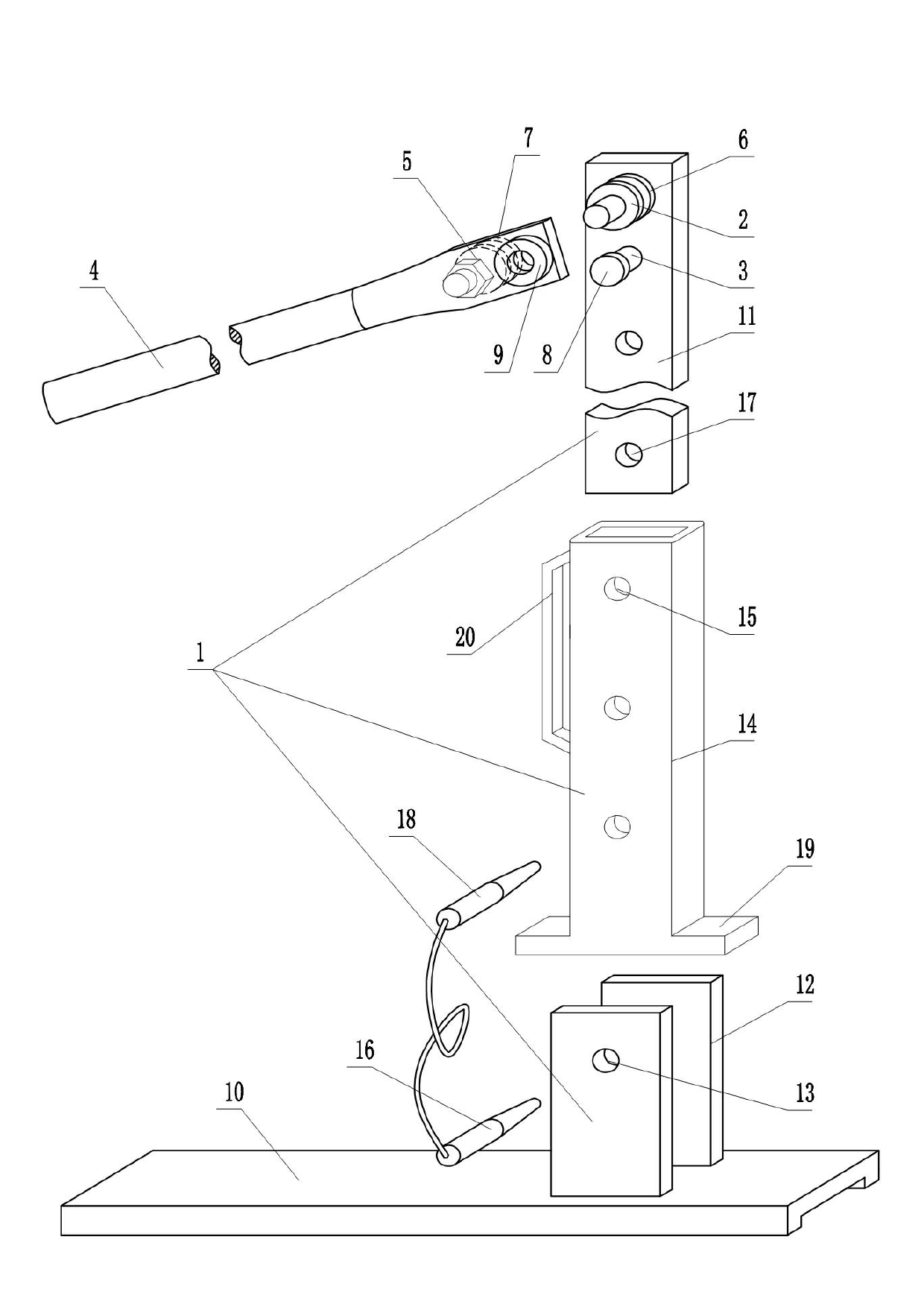

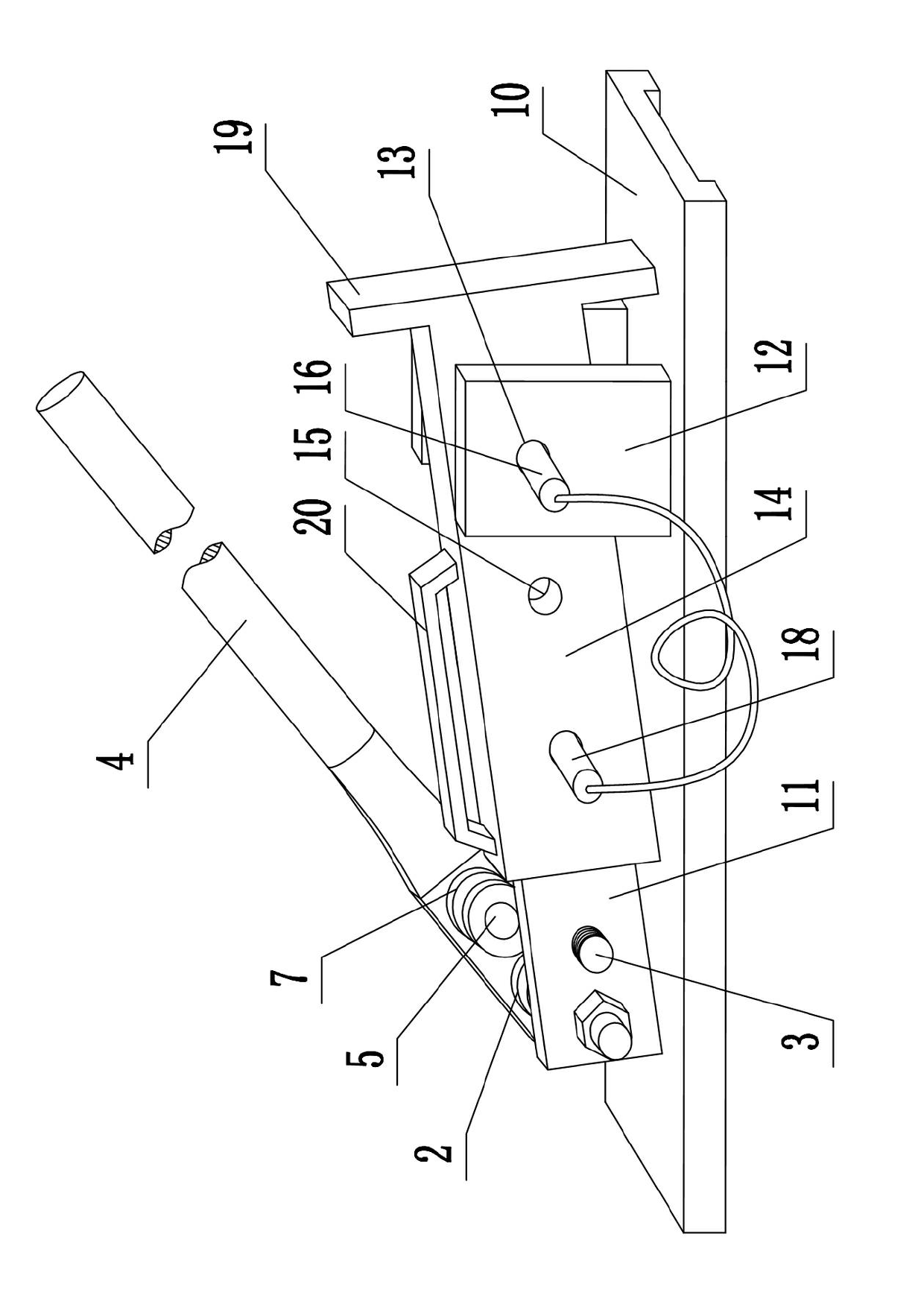

[0027] Such as figure 1 , figure 2 As shown, the steel strand bender includes a bracket 1 , and a positioning cylinder 2 perpendicular to the bracket 1 is installed on the side wall of the bracket 1 . The circumferential surface of the positioning cylinder 2 is provided with two protruding rings 6 arranged at intervals. The protruding rings 6 are arranged coaxially with the positioning cylinder 2 . When the steel strand is pushed to bend around the positioning cylinder, the steel strand can be placed in the ring groove, which limits the rolling of the steel strand and prevents the radial slip of the steel strand, which plays a role in positioning the steel strand , help to ensure bending accuracy and success rate. In this embodiment, the number of protruding rings 6 is two, and three, four or more can be set during actual production, so that two, three or more ring grooves can be formed, In other words, two, three or more steel strands can be simultaneously bent, which hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com