Compressive sprayer

A sprayer and compressed technology, applied in the field of compressed sprayers, can solve the problems of pesticide spillage, short service life, and affecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

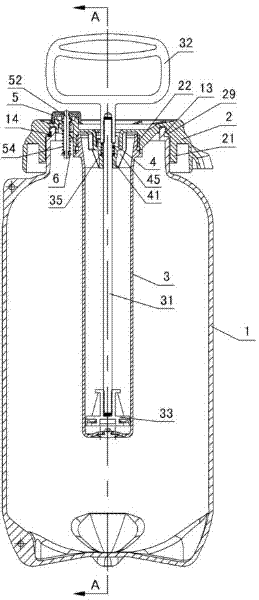

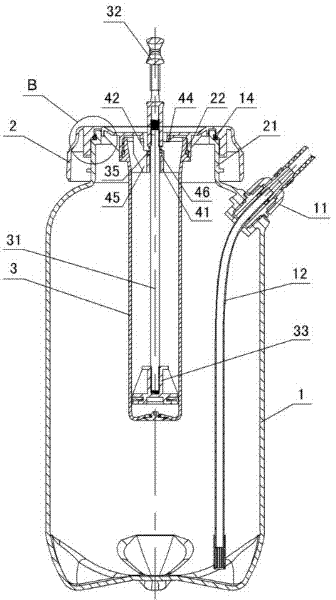

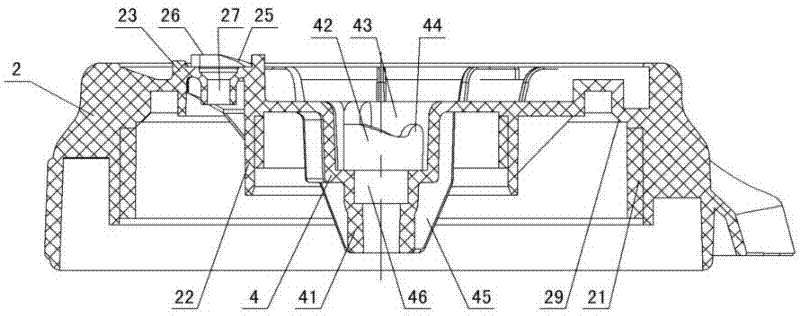

[0016] The present invention relates to a compressed sprayer, such as Figure 1-Figure 9As shown, it includes a barrel body 1 and a barrel cover 2, a safety valve device is arranged on the barrel cover, and a connecting ring 21, an installation ring 22 and a handle screw clamping mechanism are formed in the barrel cover, and the connecting ring of the barrel cover and the opening of the barrel body There is a sealing device between the parts, the connecting ring is formed with an internal thread, the internal thread is connected with the external thread of the mouth of the barrel body 1, the installation ring is connected with the pump 3, and the pumping rod 31 is installed in the bucket cover, and the pumping rod has a pumping handle 32 , the piston 33 is installed under the inflating rod, the piston matches with the inner wall of the air cylinder 3, the water suction pipe joint 11 is installed on the staving, the water suction pipe 12 is installed in the water suction pipe jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com