Automatic smooth pin pulling and assembling device

A compliant and automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of uncontrollable twisting torque, failure to pull out, pin head cannot be twisted in, pin thread damage, etc., to achieve easy operation, The effect of avoiding human intervention and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

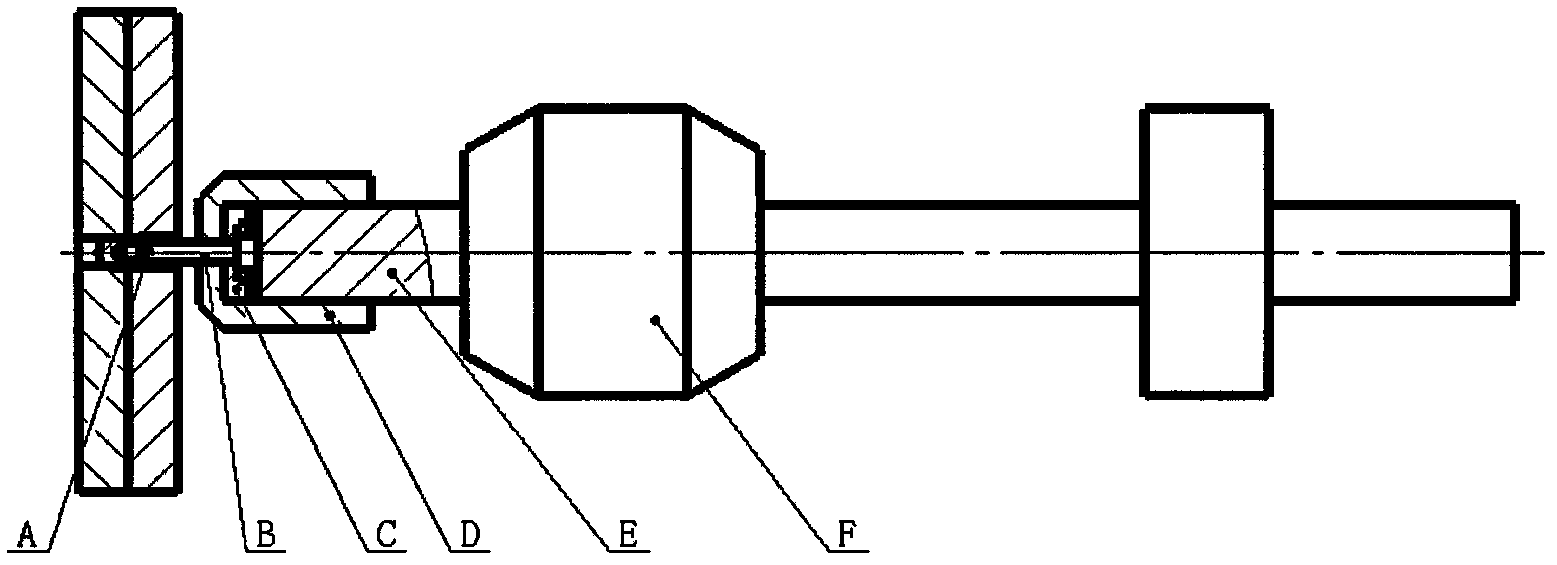

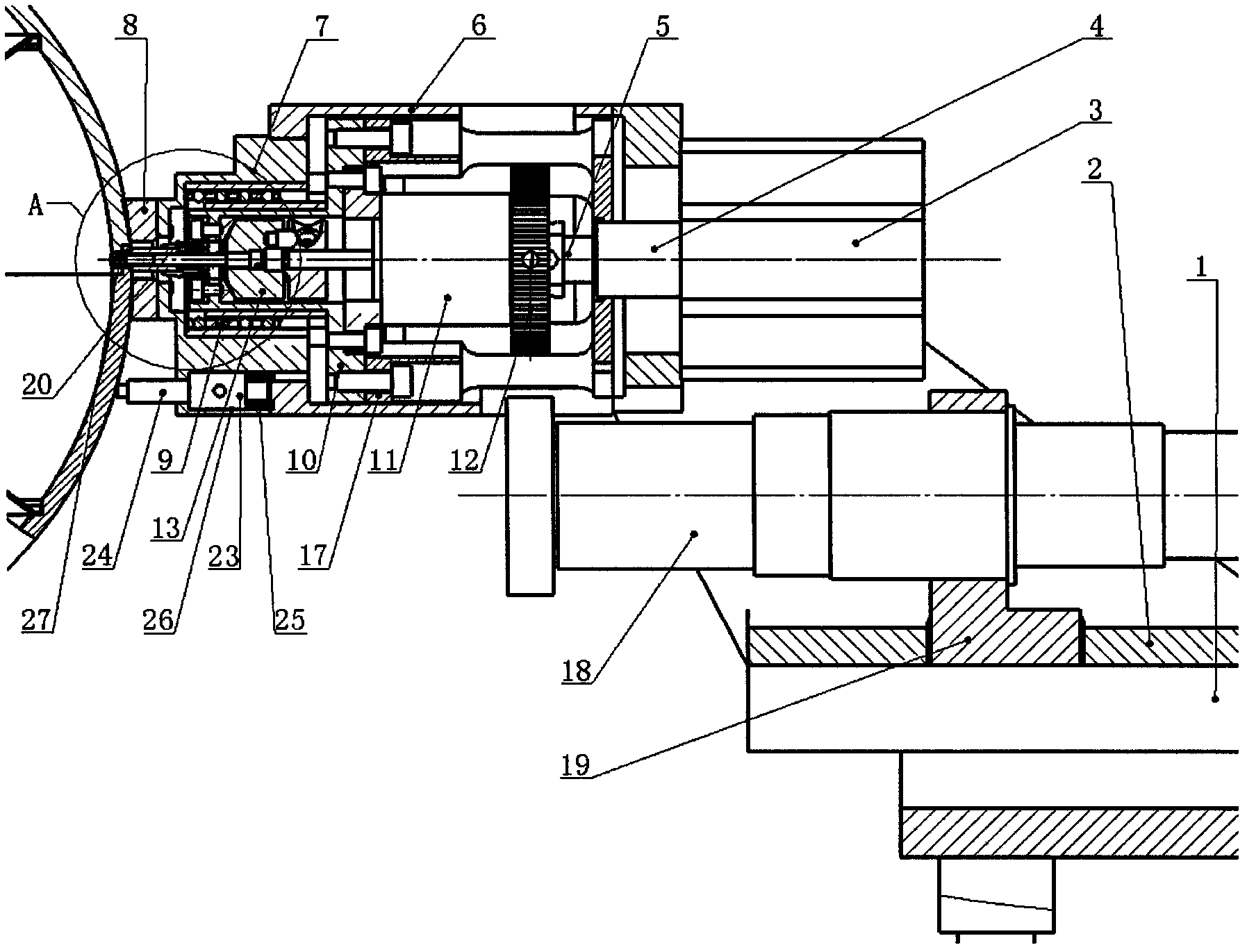

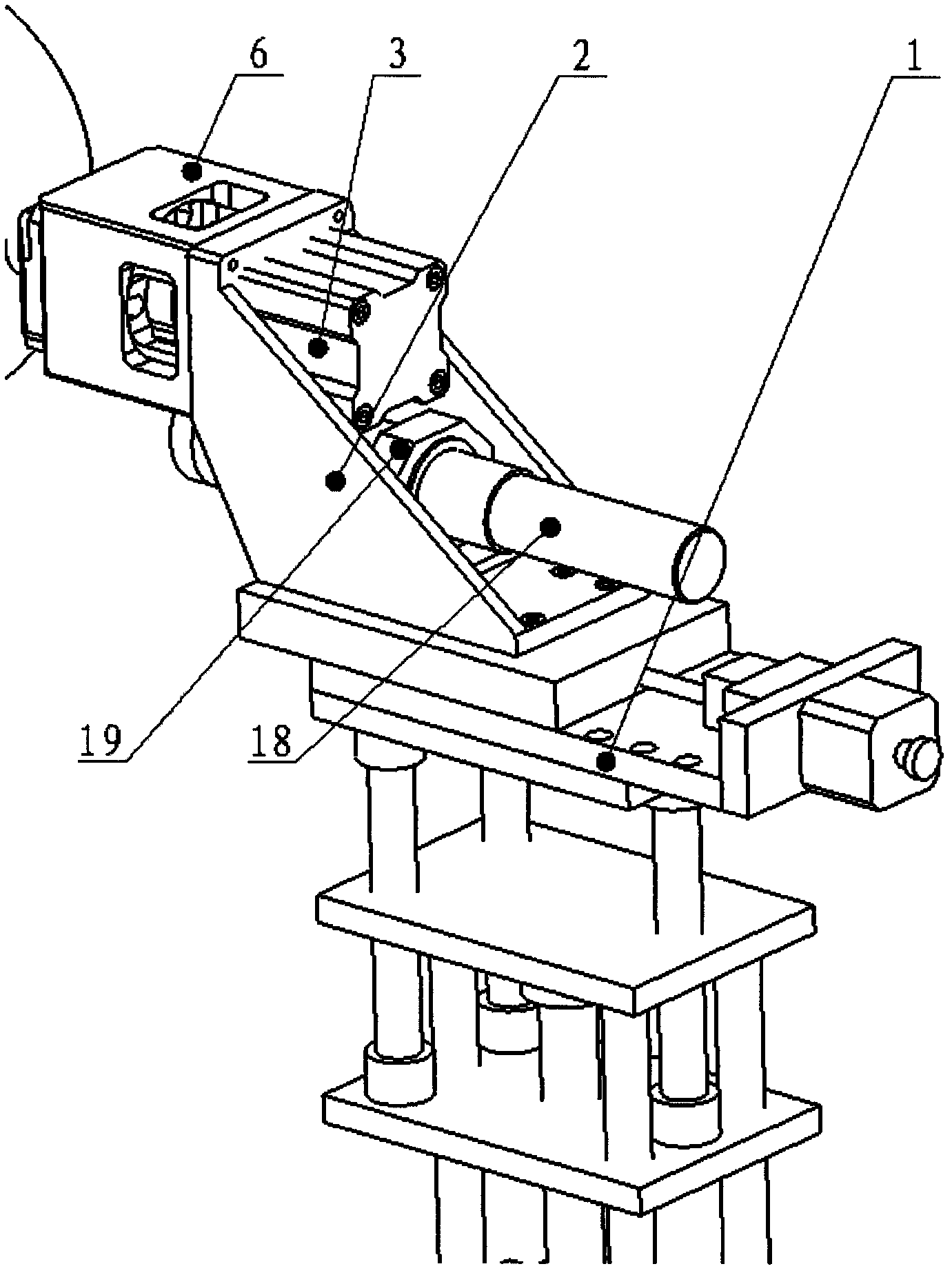

[0020] The technical solution of the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0021] See attached Figure 2-8 As shown, this kind of automatic pliable pulling and pin loading device is characterized in that: the device includes an adjustment platform 1, the fixed bracket 2 is installed on the adjustment platform 1, and can move horizontally on the adjustment platform 1, and the fixed bracket 2 A cylinder 3 is installed at the rear, and an impact block 5 is fixed at the front end of the piston rod 4 of the cylinder 3;

[0022] A front fixed mount 6 is installed at the front end of the fixed bracket 2, a centering support 7 is installed at the front end of the front fixed mount 6, and a workpiece positioning block 8 is installed at the front end of the centering support 7;

[0023] Set a linear bearing 9 in the center hole of the centering bracket 7, set a guide bracket 10 on the inner hole of the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com