Photoresponsive polymer microsphere system and preparation method thereof

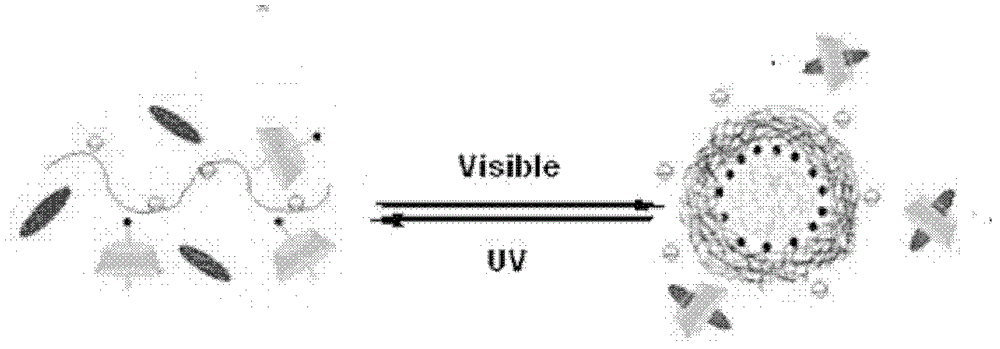

A polymer and light-responsive technology, applied in the field of intelligent polymer materials (responsive polymer materials), can solve the problems of difficult and precise control of the proportion and properties of the hydrophobic part of polymers, irreversible response behavior, high energy, etc., to achieve rapid and reliable Significant changes in light control and light transmission, reversible formation and disintegration, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve the sodium alginate-tetradecyltrimethylammonium bromide complex in the MES solution (concentration of 5%) and stir for 30 minutes to obtain the polymer to form microspheres. Then adjust the pH of the liquid to 14, add α-cyclodextrin (concentration of 5%), and then add monocarboxyazobenzene (concentration of 1.25%) to the system to obtain a polyelectrolyte with UV-visible light response Microspheres. The structure and size of the polymer microspheres are as attached figure 2 Shown in the scanning microscope photo.

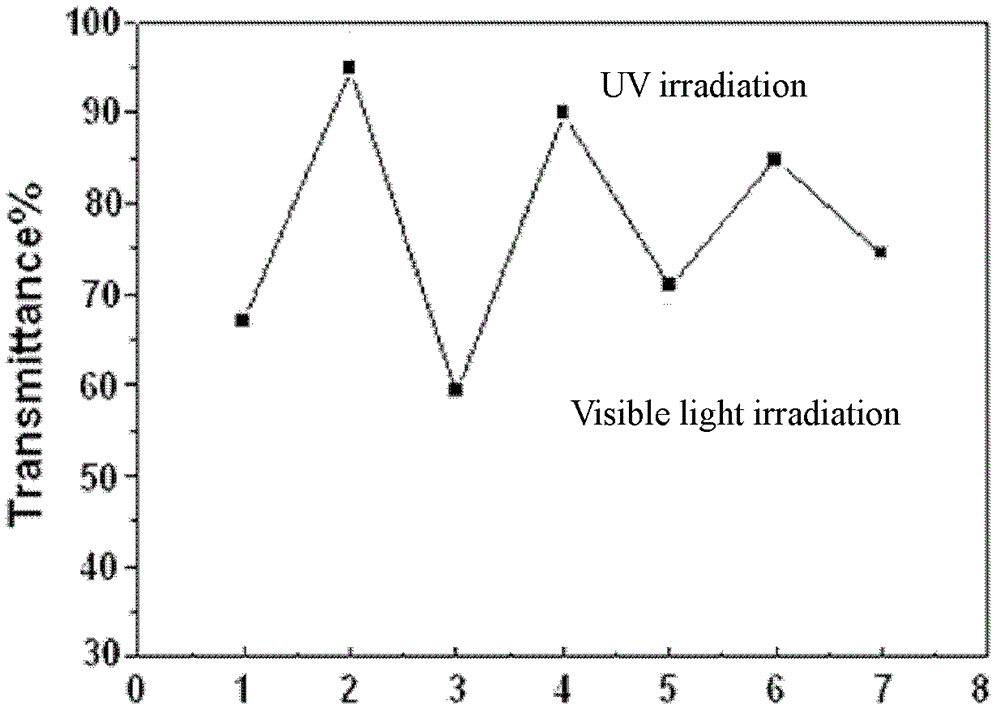

[0025] Response to UV-Visible light: When the resulting microsphere system was placed under a 500W UV lamp for 10 minutes, the light transmittance of the system rose from 65% to 95%, indicating that the microspheres in the system collapsed. When placed again under a 500W incandescent lamp for 10 minutes, the light transmittance of the system dropped from 95% to 55%, indicating that microspheres were regenerated. As attached image 3 As shown, the pr...

Embodiment 2

[0027] Polyacrylic acid grafted with dodecyl group (grafting rate 15%) was dissolved in water to prepare an aqueous solution with a concentration of 1.5%, and stirred for 3 hours to form microspheres. Then add hydroxypropyl β-cyclodextrin (concentration 1%), stir to dissolve. Then add dicarboxyazobenzene (concentration of 0.125%) to the system to obtain polyelectrolyte microspheres with UV-visible light response.

[0028] Response to ultraviolet-visible light: When the obtained microsphere system is placed under a 200W ultraviolet lamp for 1 hour and minutes, the light transmittance of the system rises from 50% to 90%, indicating that the microspheres in the system collapse. When placed under a 200W incandescent lamp for 1 hour and minutes, the light transmittance of the system dropped from 90% to 60%, indicating that microspheres were regenerated. This process of disintegration and formation of microspheres can be repeated many times with changes in ultraviolet-visible light.

Embodiment 3

[0030] Dissolve the polylysine grafted with tetradecyl group in an aqueous solution (sodium alginate concentration is 0.5%) and stir for 3 hours to form microspheres. Then adjust the pH of the above liquid to 4, add α-cyclodextrin (concentration 3%), and stir to dissolve it. Then add monohydroxy azobenzene (concentration of 0.75%) to the system to obtain polyelectrolyte microspheres with UV-visible light response.

[0031] Response to ultraviolet-visible light: When the obtained microsphere system was placed under a 600W ultraviolet lamp for 10 minutes, the light transmittance of the system rose from 40% to 79%, indicating that the microspheres in the system collapsed. When placed under a 200W incandescent lamp for 1 hour and minutes, the light transmittance of the system dropped from 79% to 47%, indicating that microspheres were regenerated. This process of disintegration and formation of microspheres can be repeated many times with changes in ultraviolet-visible light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com