A kind of wrinkled graphene oxide/latex flexible film and its preparation and application

A flexible thin film and graphene technology, applied in the direction of coating, etc., can solve the problems of slow recovery rate, long photoresponse time of photoactivated materials, poor stability, etc., achieve stable photodeformation performance, fast and safe preparation process, low cost The effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) At room temperature, weigh 1g of graphite oxide prepared by the improved Hummers method, measure 100mL of distilled water, transfer the two to a 200mL reagent bottle, stir for 5 minutes and then perform ultrasonication for 4h to obtain a concentration of 10mg / mL of graphene oxide dispersion.

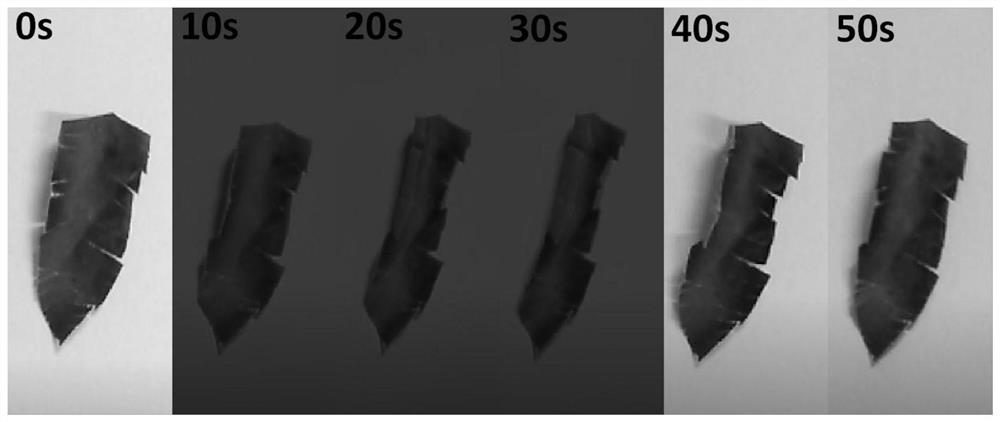

[0029] (2) After the latex film was treated with oxygen plasma for 10 minutes, a square of 6×6 cm was measured on it and cut with a manual guillotine. Fix the cut latex film with clips, and the stretching degree is 0%.

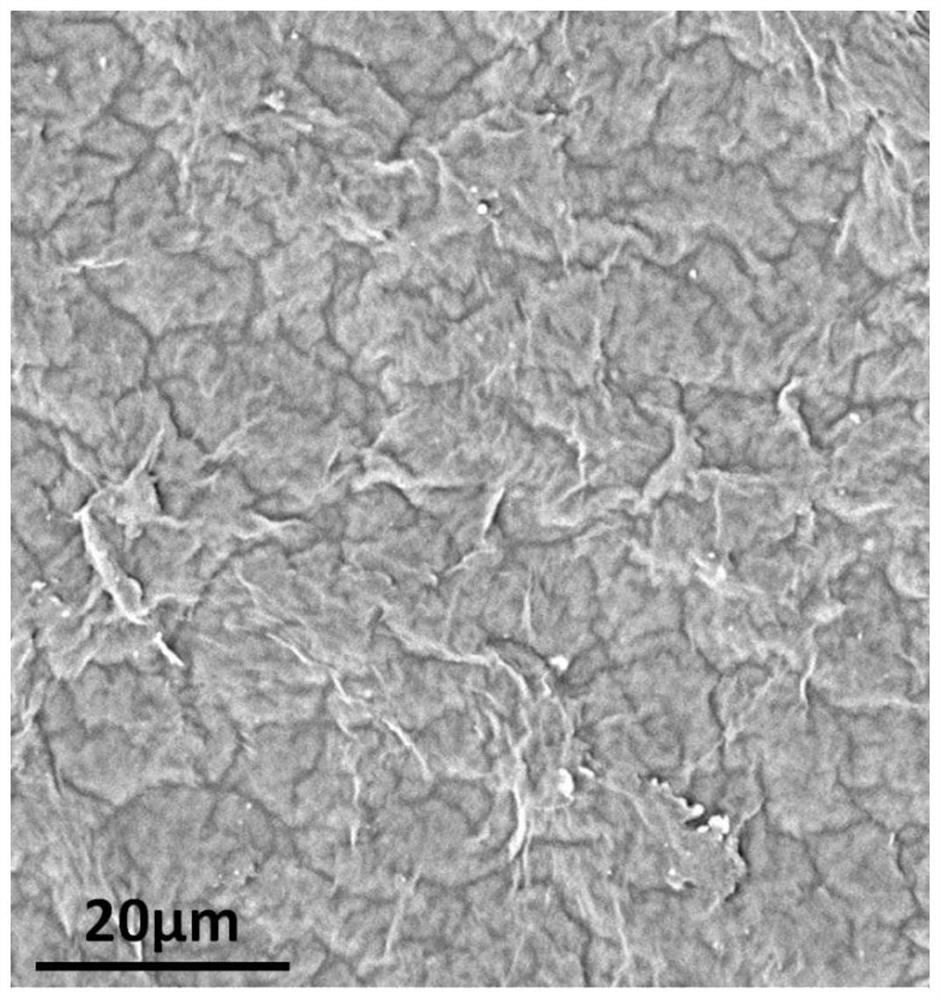

[0030] (3) Pour the graphene oxide dispersion on the petri dish, absorb the graphene oxide dispersion with a brush, and brush evenly on the latex film, then place it in an infrared lamp (20mW / m 2 ) to dry, each drying time is 50s, and after 6 times of drying, the graphene oxide / latex flexible deformable film is obtained. figure 2 It is the SEM photo of the graphite oxide side, from which we can see the wrinkled morphology of the graphene oxide coating.

...

Embodiment 2

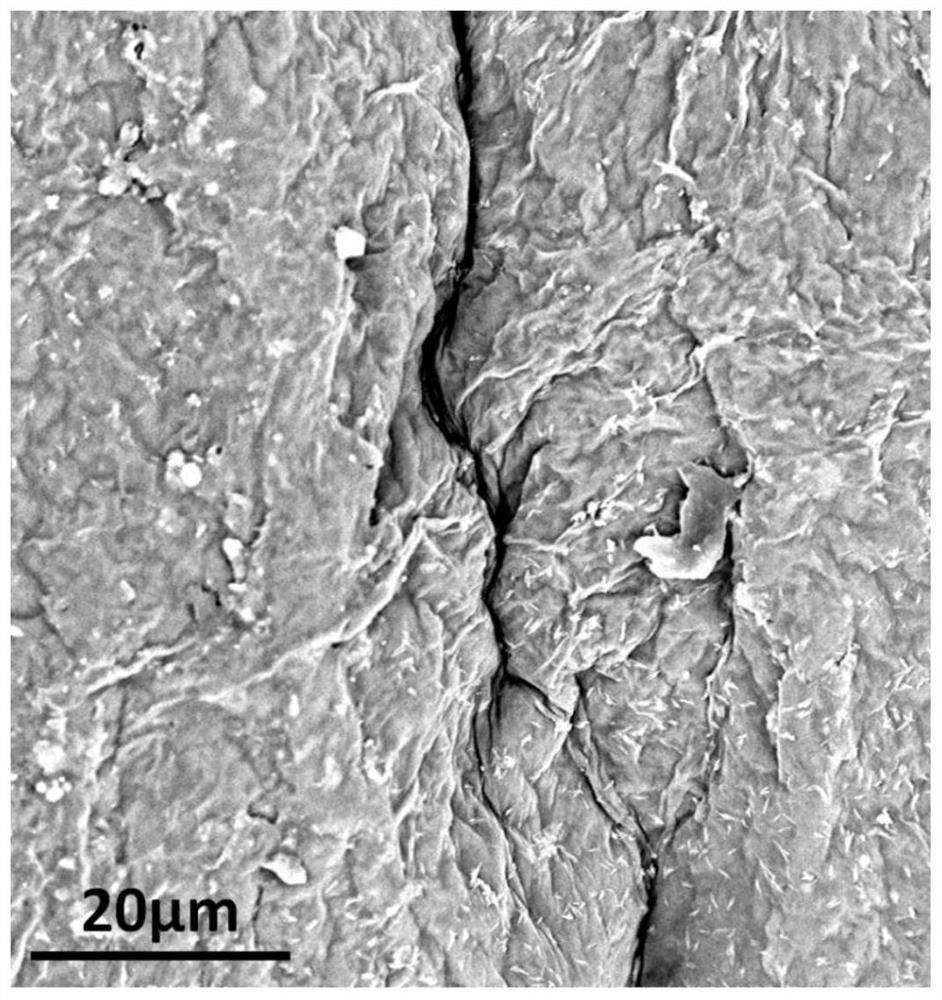

[0033] According to the method of embodiment 1, except that the length and width of the square latex film of 6 × 6cm after plasma treatment in embodiment 1 are all stretched to 7.2cm and fixed with clips, all the other are the same as embodiment 1, take off the fixed film Clips, so that the film naturally stretches until it no longer changes, that is, a wrinkled graphene oxide / latex film with a stretching degree of 20%, image 3 It is the SEM photo of the graphite oxide side. It can be seen from the figure that the surface of the graphene oxide coating has more wrinkles and a greater degree of deformation. The deformation effect and recovery degree of the wrinkled graphene oxide / latex film prepared in this embodiment are basically the same as those of the sample in Example 1.

Embodiment 3

[0035] According to the method of embodiment 1, except that the length and width of the square latex film of 6 × 6cm after plasma treatment in embodiment 1 are all stretched to 9.0cm and fixed with clips, all the other are the same as embodiment 1, take off the fixed film Clips, so that the film naturally stretches until it does not change, that is, a wrinkled graphene oxide / latex film with a stretching degree of 50%, Figure 4 It is the SEM photo of the graphite oxide side, from which it can be seen that the mechanical deformation causes the graphene oxide coating to show periodic wrinkles. The deformation effect and recovery degree of the wrinkled graphene oxide / latex film prepared in this embodiment are basically the same as those of the sample in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com