Tie-back self-lock mechanism for suspended packer

A hanging packer and self-locking technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of unsealed pipe string, failure of seal between anchor claw and body, and failure of pipe string to be raised, and achieve reliable sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

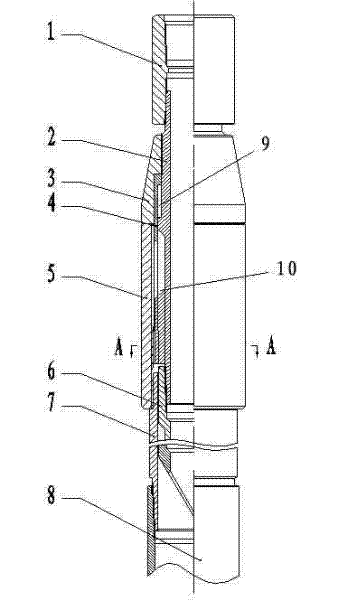

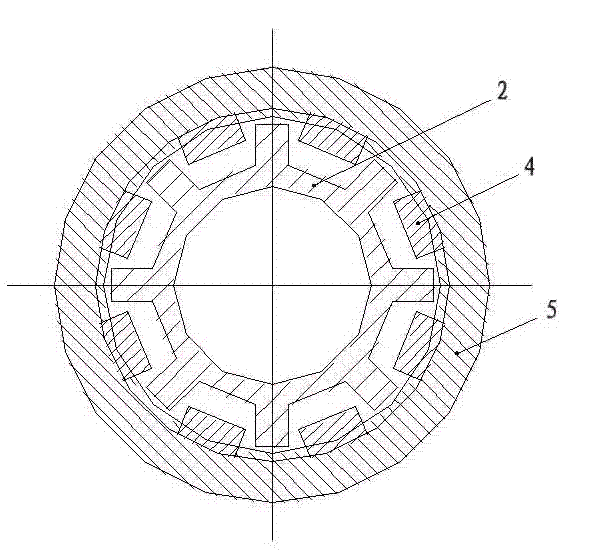

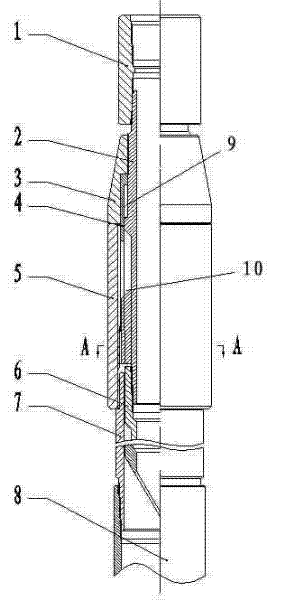

[0025] The invention discloses a tie-back self-locking mechanism for a suspended packer, which comprises a tie-back device and a self-locking device. tube; the self-locking device includes an undercut connector, a tie-back barrel and a lower joint; the upper joint, the central tube, the claw limit sleeve and the tie-back intubation are threaded from top to bottom, and the The above-described undercut connector, return barrel and lower joint are connected by threads from top to bottom, the lower end of the claw is provided with a trapezoidal male thread, and the lower end of the undercut connector is provided with a trapezoidal female thread that matches the claw. The spring claw slides axially up and down in the chute formed between the central tube and the spring claw limiting sleeve, the return sleeve is located under the undercut connector, and the return inserting tube is located under the spring claw.

Embodiment approach

[0027] The best implementation mode of the present invention is as follows:

[0028] The structure and connection relationship of the present invention: the present invention includes a tie-back device and a self-locking device. The tie-back device is composed of an upper joint 1, a central tube 2, a claw limit sleeve 3, a claw 4, and a tie-back intubation tube 6. The lock device is composed of an undercut connector 5, a return barrel 7 and a lower joint 8; the lower end of the claw 4 has a trapezoidal male button thread, the lower end of the undercut connector 5 has a trapezoidal female button thread matching the claw 4, and the claw 4 It can slide up and down in the axial direction in the chute formed by the center tube 2 and the claw limit sleeve 3. The lower end of the center tube 2 is evenly distributed with an axial limit shoulder, which limits the claw 4 from rotating in the circumferential direction and can only rotate along the Sliding in the axial direction; there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com