Fully mechanized mining face hydraulic support beam-type retracting device

A technology of fully mechanized mining face and hydraulic support, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of shortening the auxiliary time of hydraulic support relocation of fully mechanized mining face, high labor intensity, slow retraction speed, etc. , to achieve the effect of improving the speed of retracting, relocating and reversing the support of the fully mechanized mining face, improving high production and efficiency, safety, stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

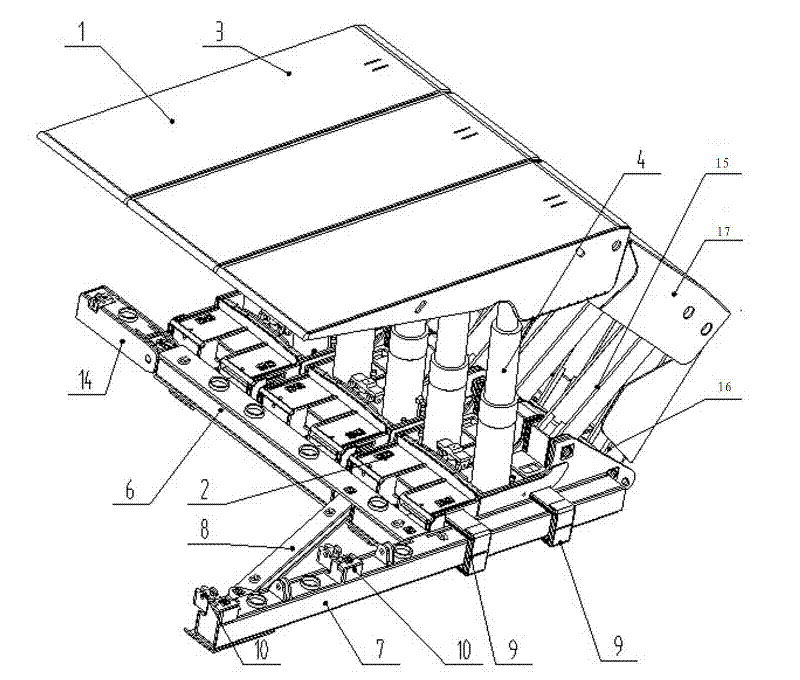

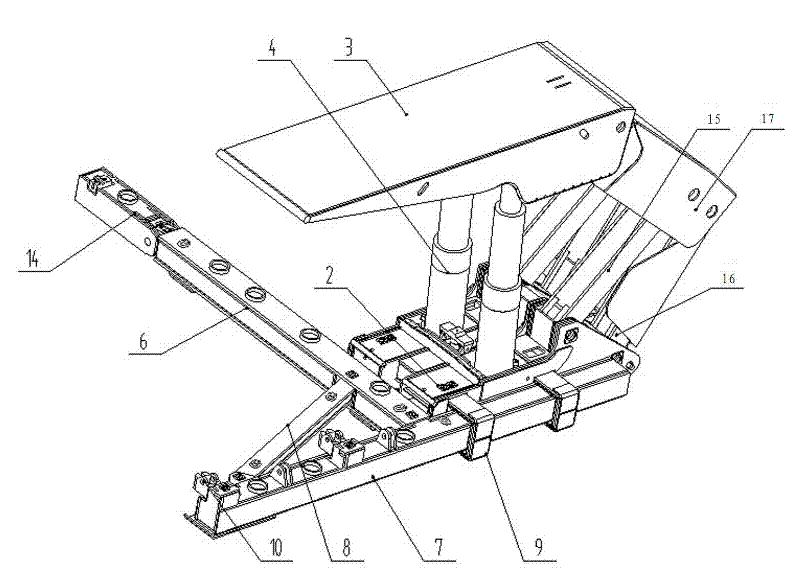

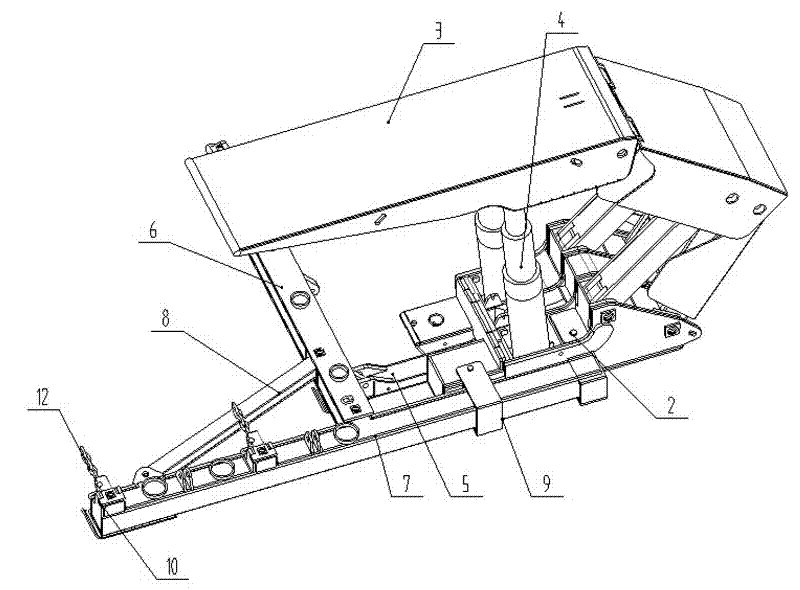

[0016] The hydraulic support beam type retraction device of the fully mechanized mining face, such as figure 1 As shown, it includes at least three retraction shielding brackets arranged side by side. The retraction shielding bracket 1 includes a base 2, a front connecting rod 15, a rear connecting rod 16, a shielding beam 17, and a top beam 3. Between the base and the top beam It is connected with a column 4, and a push rod 5 and a push cylinder are arranged through the base, and a two-way lock is arranged in the hydraulic control system of the push cylinder. Well known, one end of the push rod is hinged with the end of the piston rod of the push cylinder, such as figure 2 , 3 As shown, the beam type retraction device also includes a crossbeam 6 located in front of each retraction shield support base 2, a longitudinal beam 7 positioned outside the side retraction shield support 18, and a diagonal brace connected between the crossbeam and the longitudinal beam. Rigid triang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com