fuel injection valve

A fuel injection valve and fuel injection technology, which are applied to fuel injection devices, charging systems, engine components, etc. to achieve the effects of atomization and conflict suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

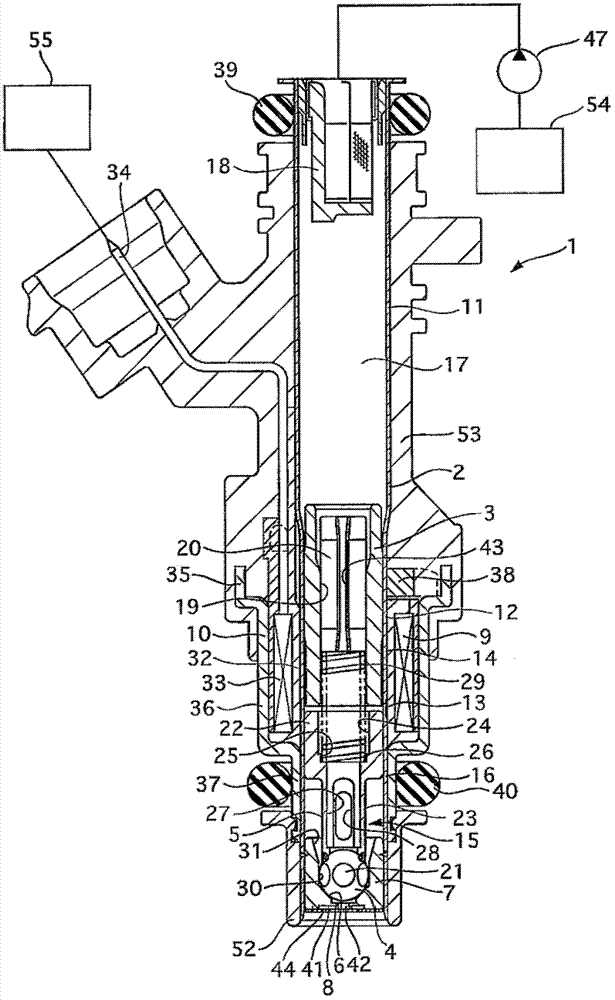

[0034] The fuel injection valve 1 of the first embodiment will be described.

[0035] [Structure of Fuel Injection Valve]

[0036] figure 1 is an axial sectional view of the fuel injection valve 1 . This fuel injection valve 1 is used in an automobile engine and the like.

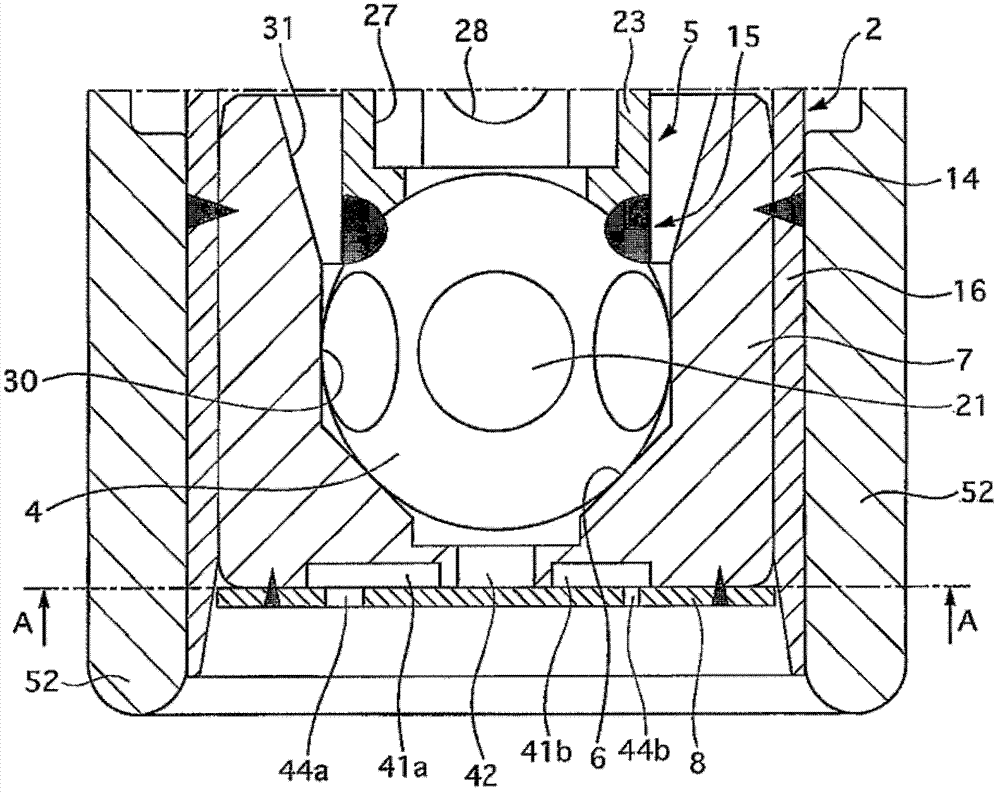

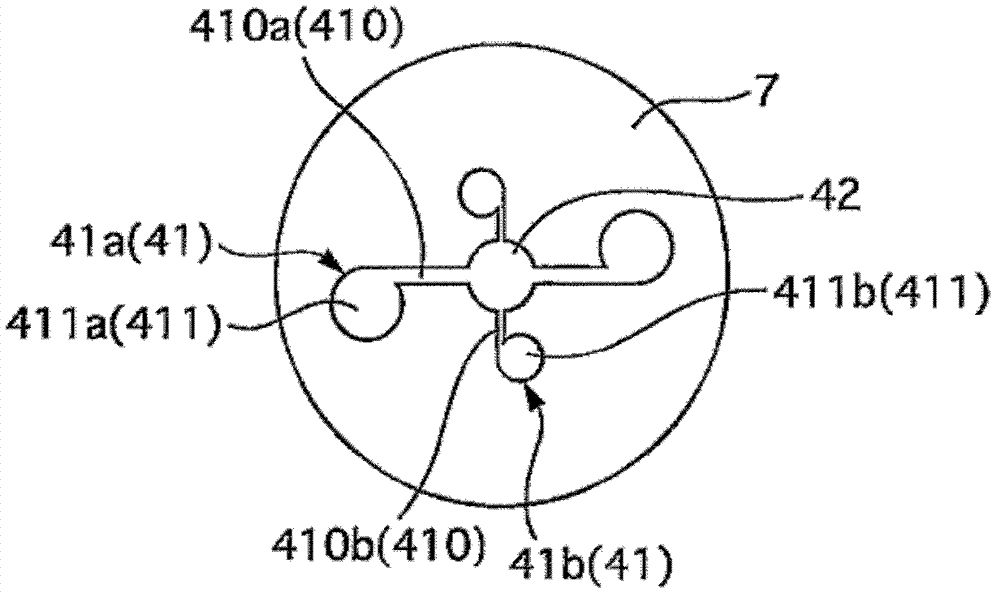

[0037] The fuel injection valve 1 has: a magnetic cylinder body 2, a core cylinder body 3 accommodated in the magnetic cylinder body 2, a valve body 4 slidable in the axial direction, a valve shaft 5 integrally formed with the valve body 4, and a valve shaft through which the valve is closed. The valve seat part 7 of the valve seat 6 that is closed by the valve body 4, the nozzle plate 8 with the injection hole that injects fuel when the valve is opened, the electromagnetic coil 9 that makes the valve body 4 slide in the valve opening direction when the valve is energized, and the yoke 10 that induces magnetic flux .

[0038] The magnetic cylinder 2 is made of, for example, a metal pipe formed of a magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com