Fuel injection valve

A fuel injection valve and fuel technology, which can be applied to fuel injection devices, charging systems, machines/engines, etc., can solve the problems of unstable direction or shape of spray foam, hindering the atomization of injected fuel, and increasing fuel pressure loss, etc. Achieve the effects of preventing dripping, promoting separation, and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

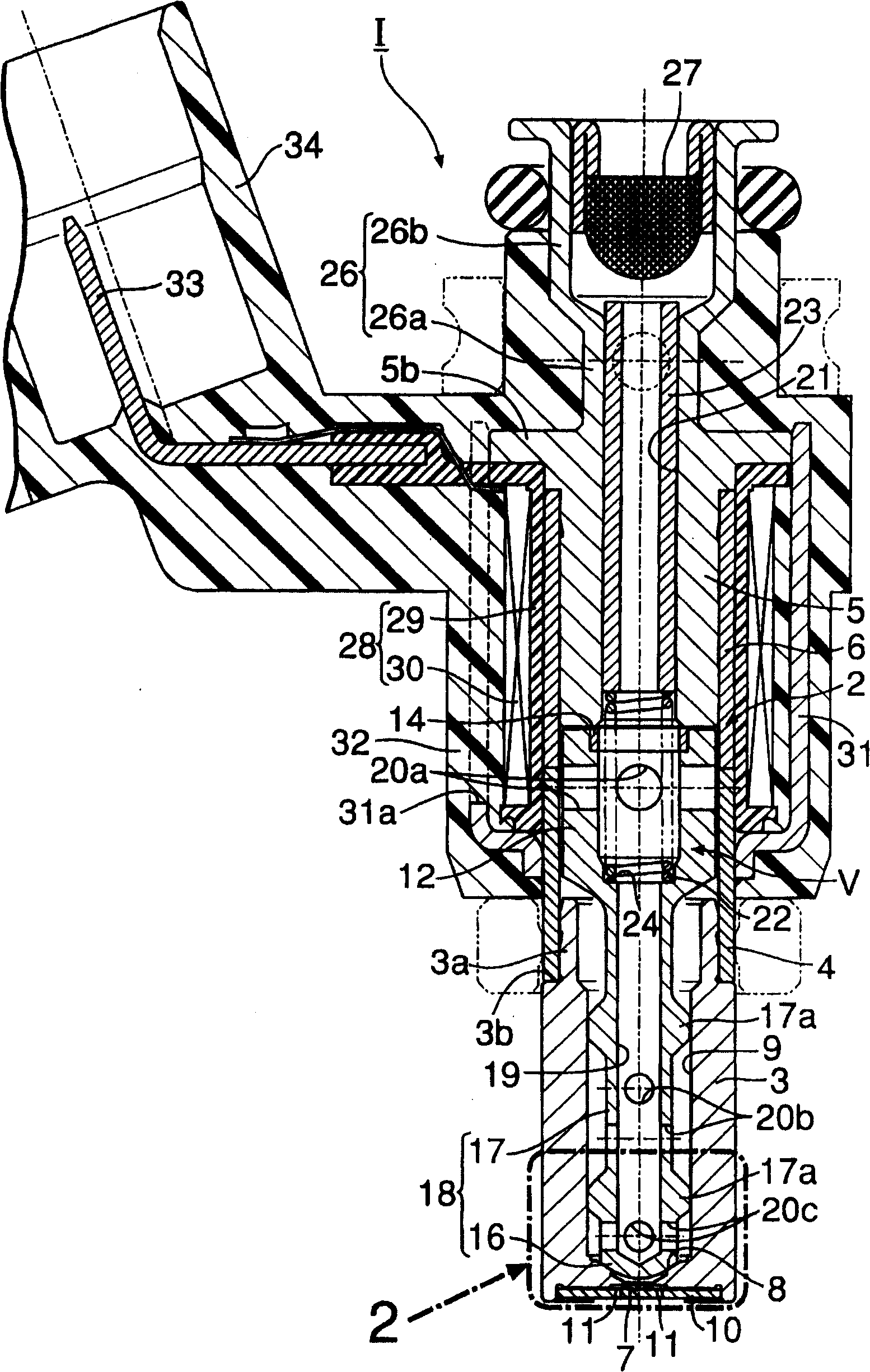

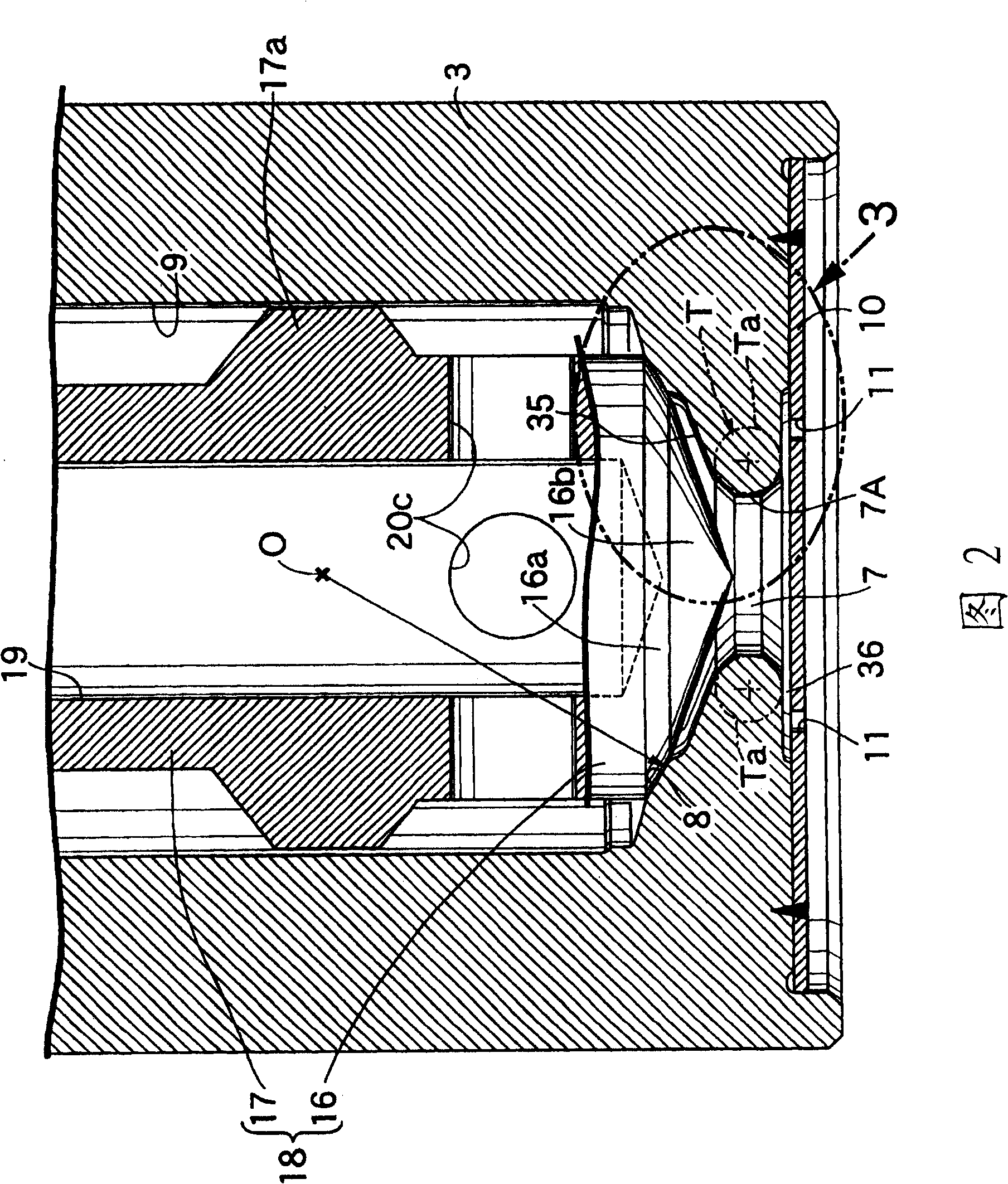

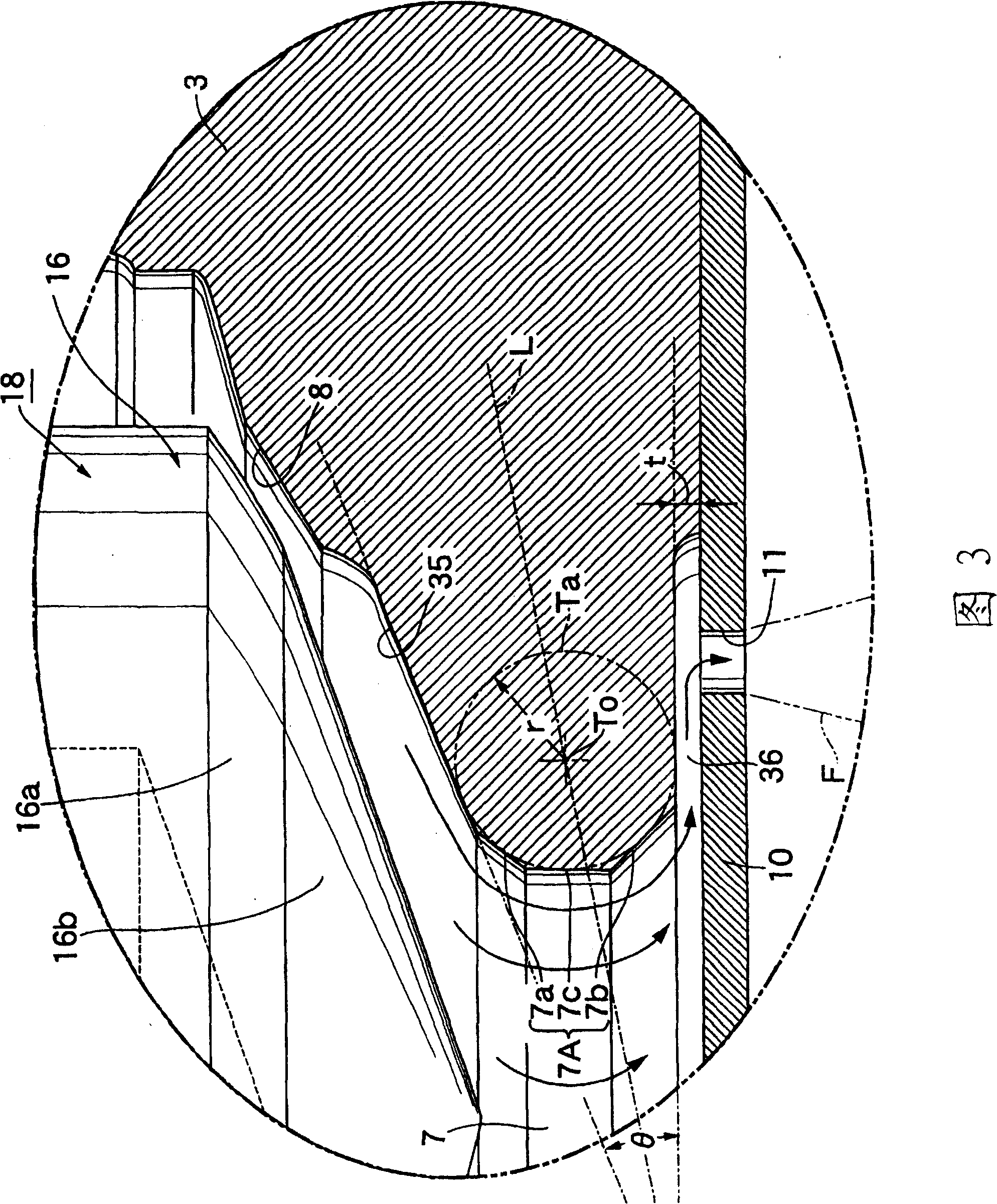

[0022] refer to figure 1 ~ Fig. 3 illustrates the embodiment of the present invention, at first in figure 1 2, the valve housing 2 of the electromagnetic fuel injection valve 1 for an internal combustion engine is made of a cylindrical valve seat member 3, a magnetic cylinder 4 and a non-magnetic cylinder 6, and the valve seat member 3 has a front end. The valve seat 8 ; the magnetic cylinder 4 is coaxially coupled to the rear end of the valve seat member 3 ; the non-magnetic cylinder 6 is coaxially coupled to the rear end of the magnetic cylinder 4 .

[0023] The valve seat member 3 has an annular shoulder 3b from its outer peripheral surface, and has a connecting cylindrical portion 3a at the rear end portion, and the connecting cylindrical portion 3a protrudes toward the magnetic cylinder 4 side. The inner peripheral surface of the front end of the magnetic cylinder 4, and the front end surface of the magnetic cylinder 4 is brought into contact with the annular shoulder 3b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com