Fuel reformer and fuel supply system using the same

A technology of fuel supply system and reforming device, which is applied in the direction of charging system, liquid fuel feeder, combustion air/combustion-air treatment, etc. The problem of uneven performance, etc., achieves the effect of suppressing adverse effects, suppressing adverse effects on the environment, and suppressing the decline in combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

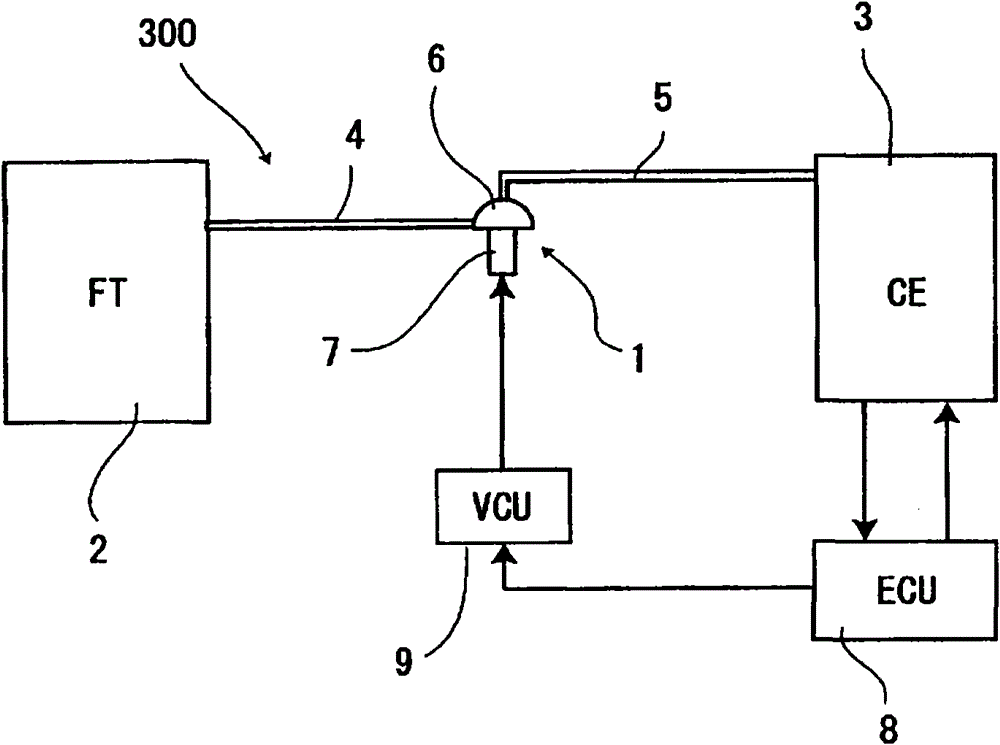

[0095] Such as figure 1 As shown, the fuel reforming device 1 of the present invention is arranged on the pipes 4 and 5 connecting the fuel tank 2 and the internal combustion engine 3 to form a first fuel supply system 300, and is a reforming part in which liquid fuel flows 6, and an ultrasonic transducer (specifically, a bolted Langevin transducer (BLT)) 7 for applying ultrasonic vibration to the reforming portion 6 . Furthermore, the BLT 7 is controlled by a vibrator control unit (VCU) 9 that outputs a signal corresponding to the signal based on a signal from an engine control unit (ECU) 8 that controls the internal combustion engine 3 . As the above-mentioned internal combustion engine 3, it may be a gasoline engine or a diesel engine that mixes liquid fuel with air through a carburetor and sends it to a combustion chamber, or may be a gasoline engine or a diesel engine equipped with a fuel injection pump that directly injects liquid fuel into a combustion chamber. Diesel ...

Embodiment 2

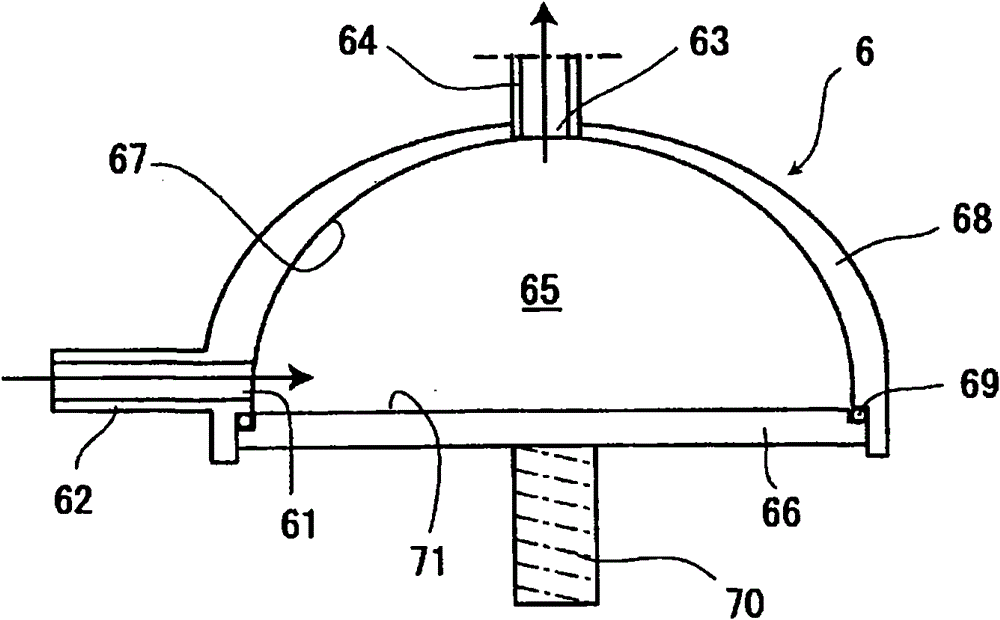

[0102] In the reforming part 6 of the first embodiment, the outflow direction of the liquid fuel is the same as the direction in which the ultrasonic vibration is applied. Figure 4 The reforming unit 6A of the fuel reforming device 1 of the illustrated embodiment 2 is such that the outflow direction of the liquid fuel from the reforming space 65 is the direction along the swirl of the liquid fuel from the top of the reforming space 65, in other words, It is perpendicular to the application direction of the above-mentioned ultrasonic vibration. Also in the modified portion 6A shown in the second embodiment, the same effect as that in the first embodiment can be obtained. In addition, in Figure 4 In Example 2 shown, the same parts as in Example 1 or parts having the same effect are attached with the same symbols and their descriptions are omitted.

Embodiment 3

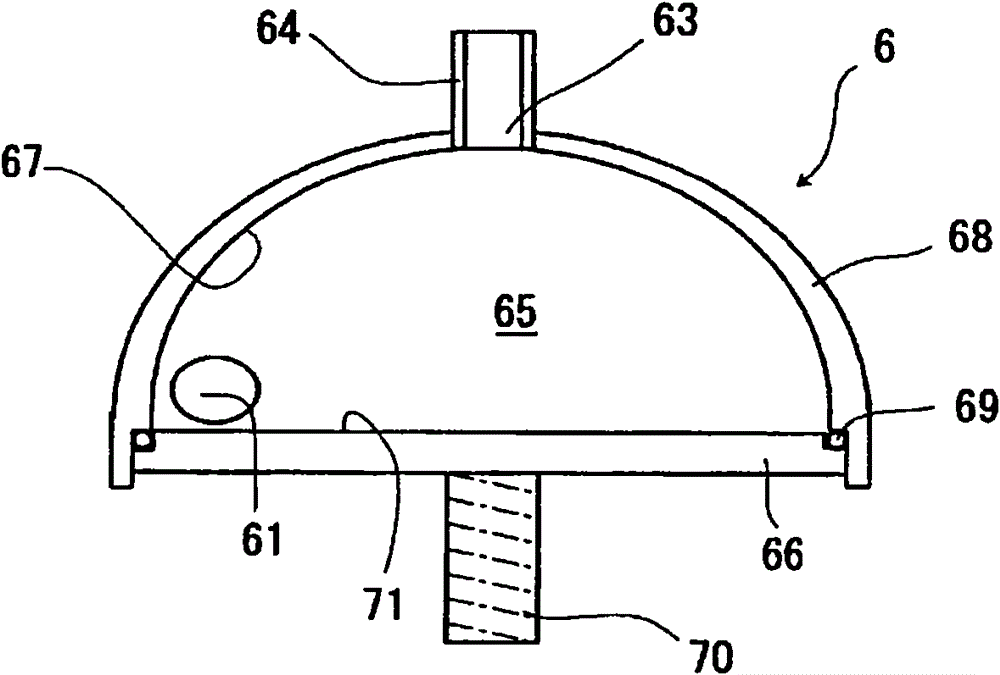

[0104] Figure 5 The reforming part 6B of the fuel reforming device 1 shown in Embodiment 3 is characterized in that the positions of the inlet 63 and the outlet 64 of the reforming part 6 in Embodiment 1 are substantially reversed, and the reforming space 65 The vibrating plate 66 necessarily has an inverted dome shape, and the vibrating plate 66 applies ultrasonic vibrations to the liquid fuel in the reforming space 65 from above the reforming space 65 . At this time, the liquid fuel flowing into the reforming space 65 from the inflow port 61 ′ moves toward the vibrating surface in a spiral shape while being exposed to ultrasonic vibrations toward the vibrating surface 71 , and moves from the outflow port 63 ′ to the vibrating surface 71 along the vibrating surface 71 ′. The internal combustion engine 3 moves. In this case as well, the same effect as in the case of the first or second embodiment described above can be obtained.

[0105] For each of the above embodiments 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com