Control device for handrail drive device

A driving device and control device technology, used in escalators, transportation and packaging, etc., can solve the problems of shortened parts life, deteriorated driving performance, and increased traction slippage, etc., to extend the life of parts, improve maintenance operations, and reduce driving performance. Degraded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

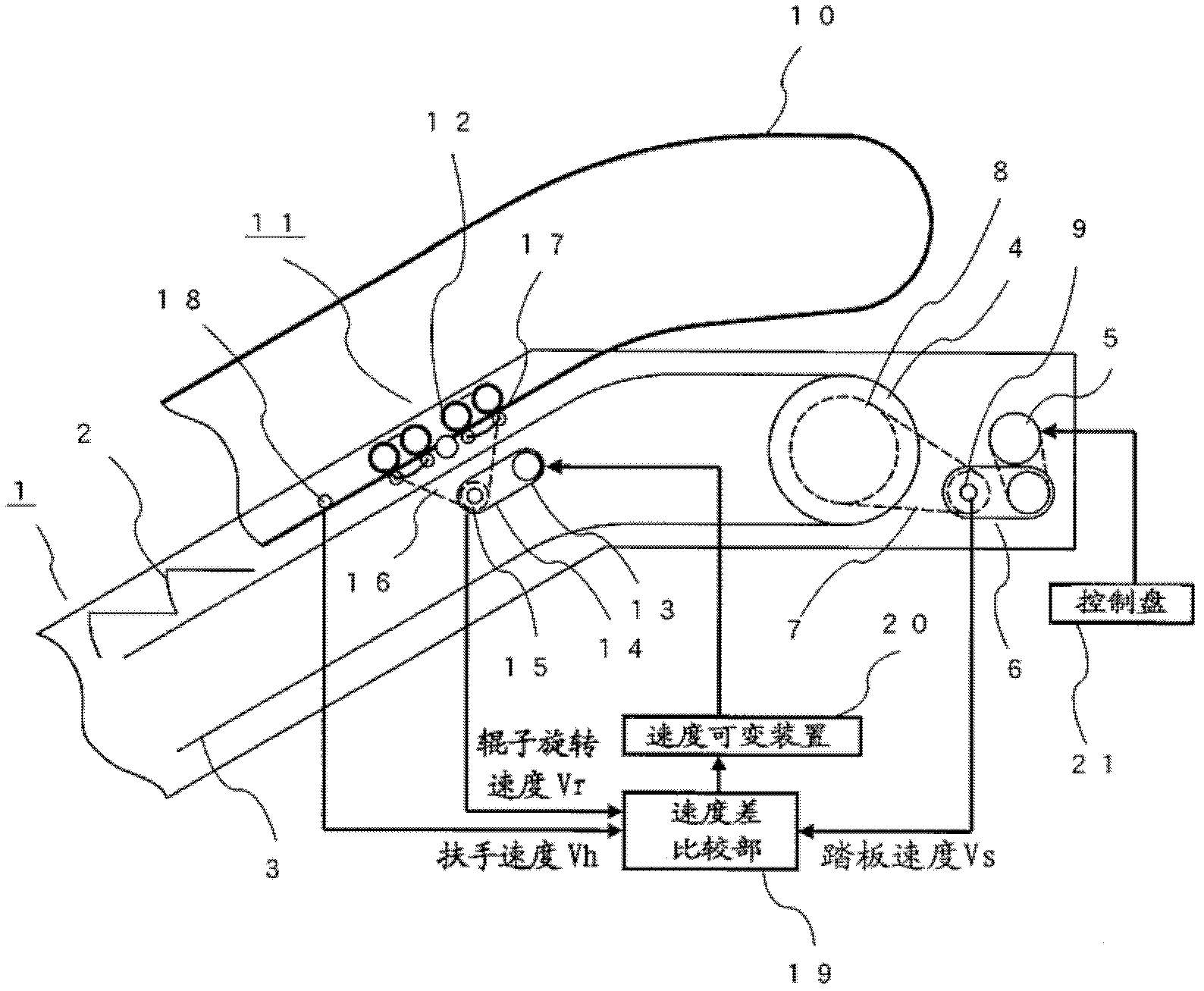

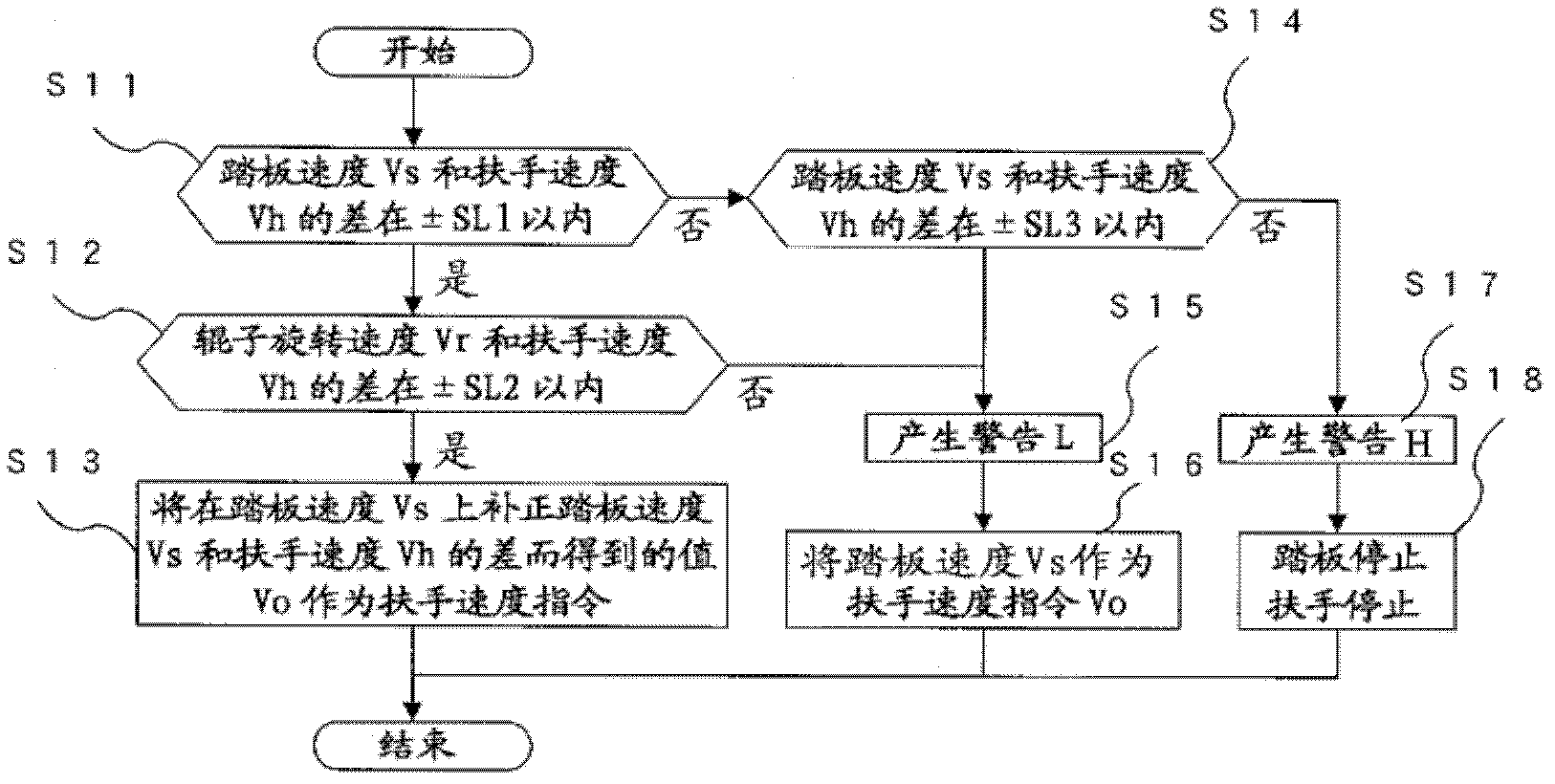

[0019] figure 1 It is a figure which shows the structure of the control apparatus of the handrail drive apparatus concerning Embodiment 1 of this invention. exist figure 1 Among them, the pedals 2 of the passenger conveyor 1 are connected to a pedal chain 3 . Power of a pedal driving machine constituted by a pedal motor 5 and a pedal reducer 6 installed on the upper portion of the passenger conveyor 1 is transmitted to the pedal chain 3 via a chain 7 , a sprocket 8 and a sprocket 4 . The handrail 10 transmits the power of the handrail driving machine constituted by the handrail motor 13 and the handrail reducer 14 to each roller 12 via the chain 16, and the handrail 10 is clamped by the rollers 12 and the pressing rollers 17, thereby driving the handrail 10. In addition, reference numeral 11 denotes a handrail driving device.

[0020] The driving speed of the pedal 2 is performed by inputting a desired speed command from the control panel 21 to the pedal driving machine. R...

Embodiment approach 2

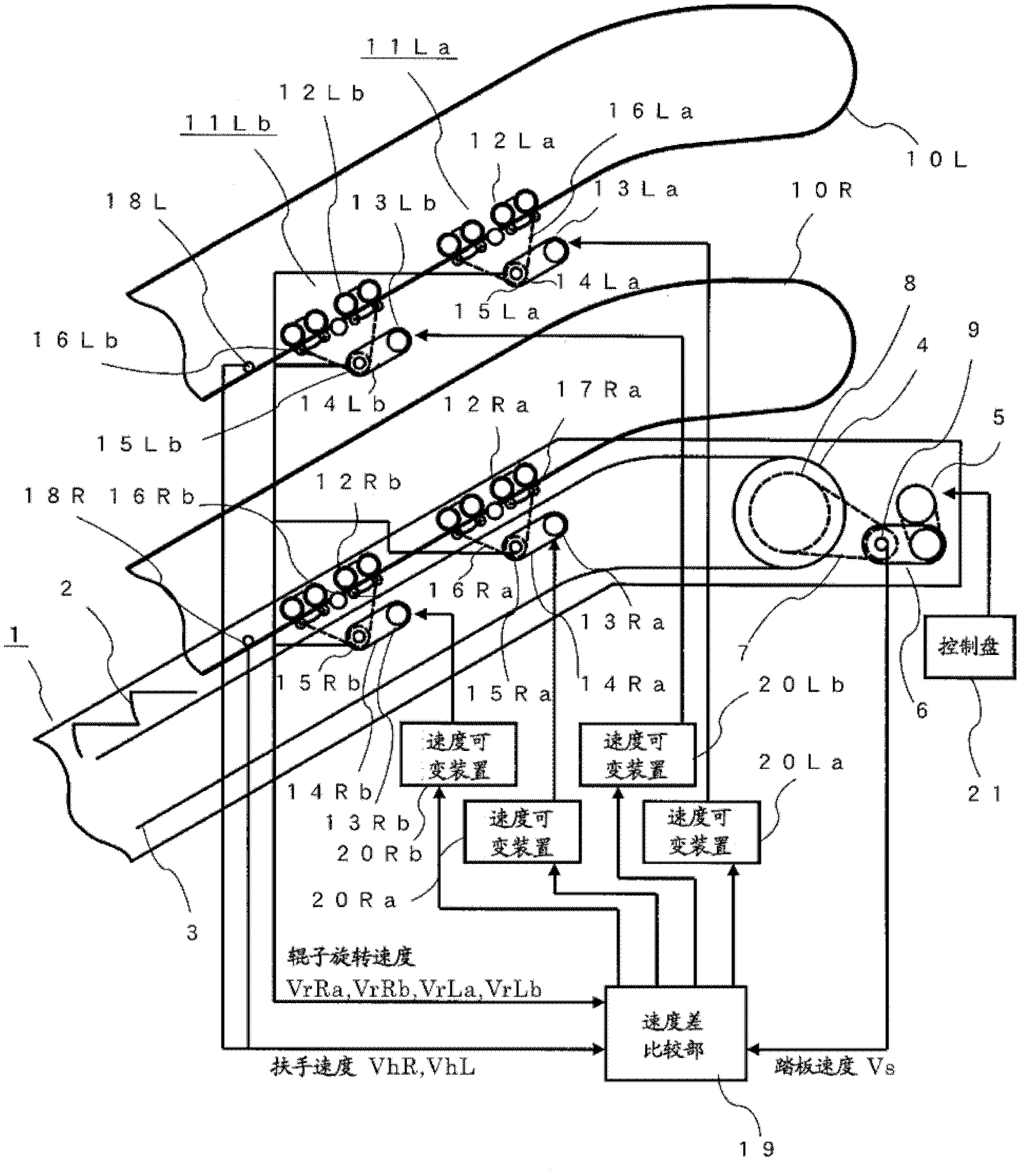

[0031] image 3 It is a figure which shows the structure of the control apparatus of the handrail drive apparatus concerning Embodiment 2 of this invention. exist image 3 Among them, the pedals 2 of the passenger conveyor 1 are connected to a pedal chain 3 . Power of a pedal driving machine constituted by a pedal motor 5 and a pedal reducer 6 installed on the upper portion of the passenger conveyor 1 is transmitted to the pedal chain 3 via a chain 7 , a sprocket 8 and a sprocket 4 .

[0032]The right (left) handrail 10R (10L) is composed of the right (left) handrail motors 13Ra, 13Rb (13La, 13Lb) and the handrail speed reducers 14Ra, 14Rb (14La, 14Lb), which are arranged separately on the left and right sides. The power of the driver for the handrail is transmitted to the rollers 12Ra, 12Rb (12La, 12Lb) via the chains 16Ra, 16Rb (16La, 16Lb), and the rollers 12Ra, 12Rb (12La, 12Lb) and the push rollers 17Ra, 17Rb (17La, 17Lb) ) pinches the armrest 10R (10L), thereby drivin...

Embodiment approach 3

[0046] Figure 5 It is a figure which shows the structure of the control apparatus of the handrail drive apparatus concerning Embodiment 3 of this invention. exist Figure 5 In this example, the pedals 2 of the passenger conveyor 1 are connected to a pedal chain 3 . Power of a pedal driving machine constituted by a pedal motor 5 and a pedal reducer 6 installed on the upper portion of the passenger conveyor 1 is transmitted to the pedal chain 3 via a chain 7 , a sprocket 8 and a sprocket 4 . The right (left) handrail 10R (10L) is composed of the right (left) handrail motors 13Ra, 13Rb (13La, 13Lb) and the handrail speed reducers 14Ra, 14Rb (14La, 14Lb), which are arranged separately on the left and right sides. The power of the driver for the handrail is transmitted to the rollers 12Ra, 12Rb (12La, 12Lb) via the chains 16Ra, 16Rb (16La, 16Lb), and the rollers 12Ra, 12Rb (12La, 12Lb) and the push rollers 17Ra, 17Rb (17La, 17Lb) ) pinches the armrest 10R (10L), thereby driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com