Internal drilling riser centralizer

a technology of riser and centralizer, which is applied in the direction of drilling pipes, drilling/well accessories, sealing/packing, etc., can solve the problems of substantial pollution of drilling mud into seawater, loss of drilling mud pressure to control the pressure, and the key seat of the drilling riser or the blowout preventer stack can literally wear all the way through the metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

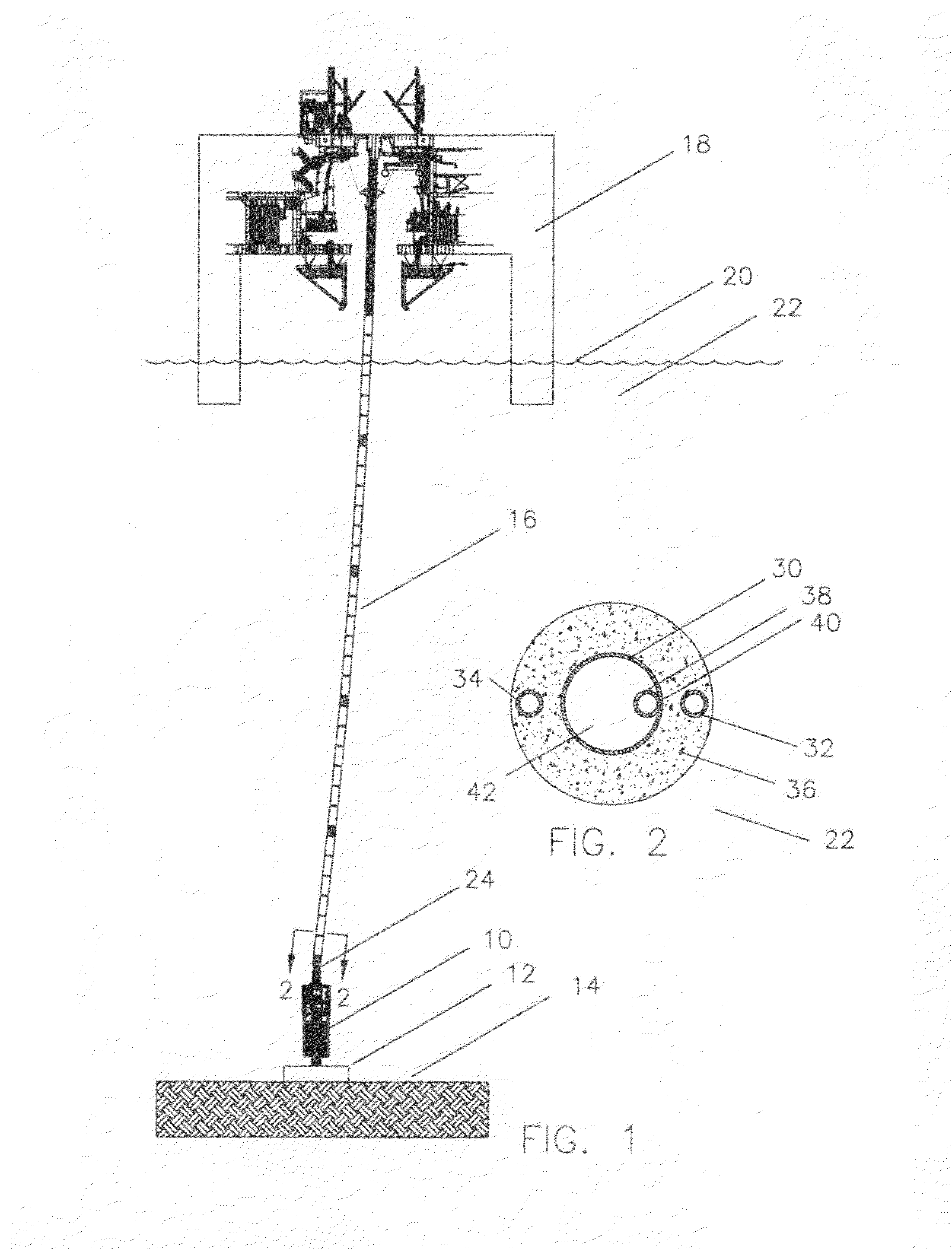

[0020]Referring now to FIG. 1, a blowout preventer stack 10 is landed on a subsea wellhead system 12 on the ocean floor 14. Drilling riser 16 extends to a drilling vessel 18 at the surface 20 of the ocean 22. At the connection of the drilling riser to the top of the blowout preventer stack is a flex joint 24 which is similar to a rubber ball joint.

[0021]Referring now to FIG. 2, riser pipe 16 is shown with an internal steel pipe 30, auxiliary pipes 32 and 34, and flotation material 36. Rotating internal pipe 38 is shown wearing a notch or keyseat 40 in the internal steel pipe 30. If the keyseat 40 wears all the way through the wall of steel pipe 30, the drilling mud 42 will leak into the ocean 22.

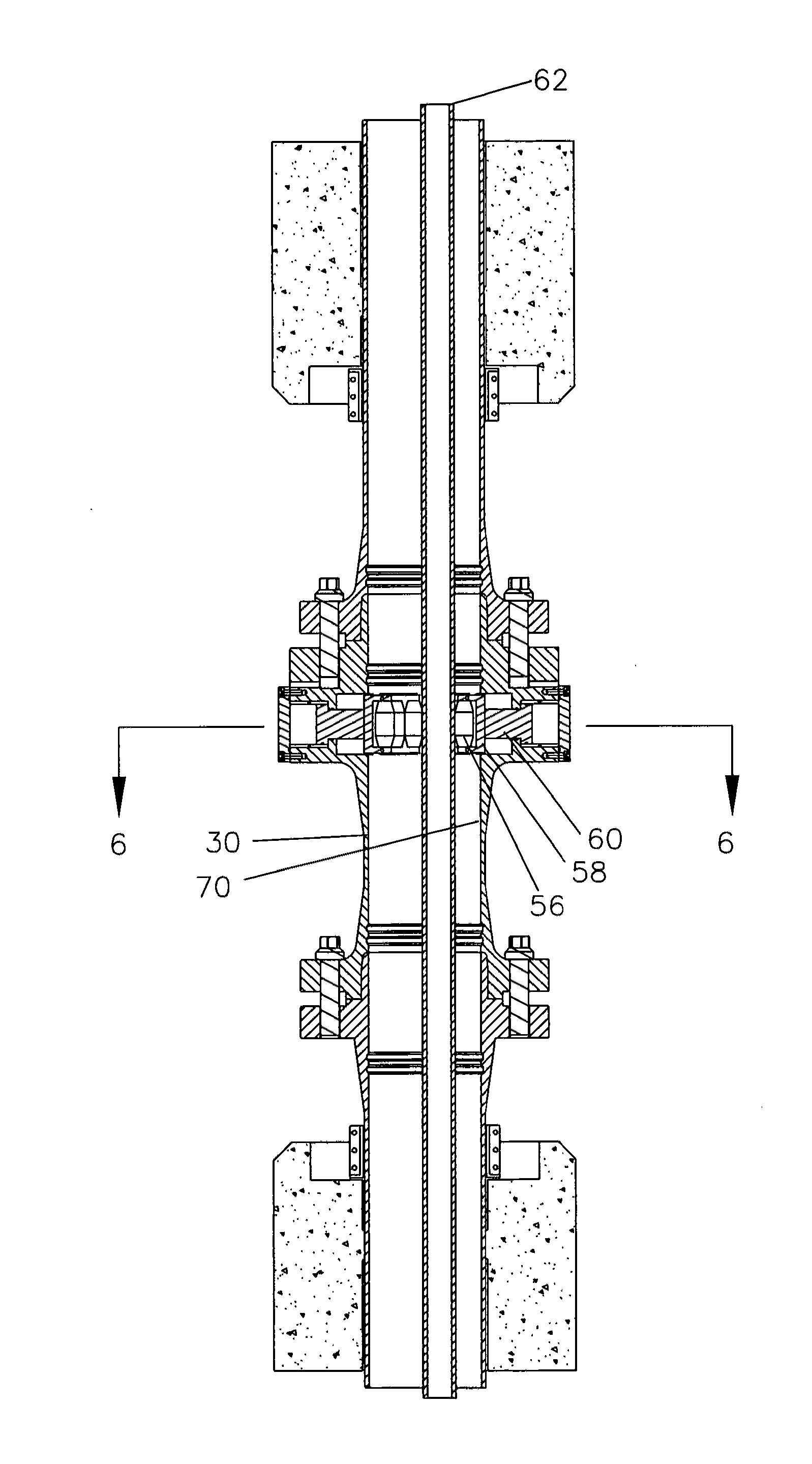

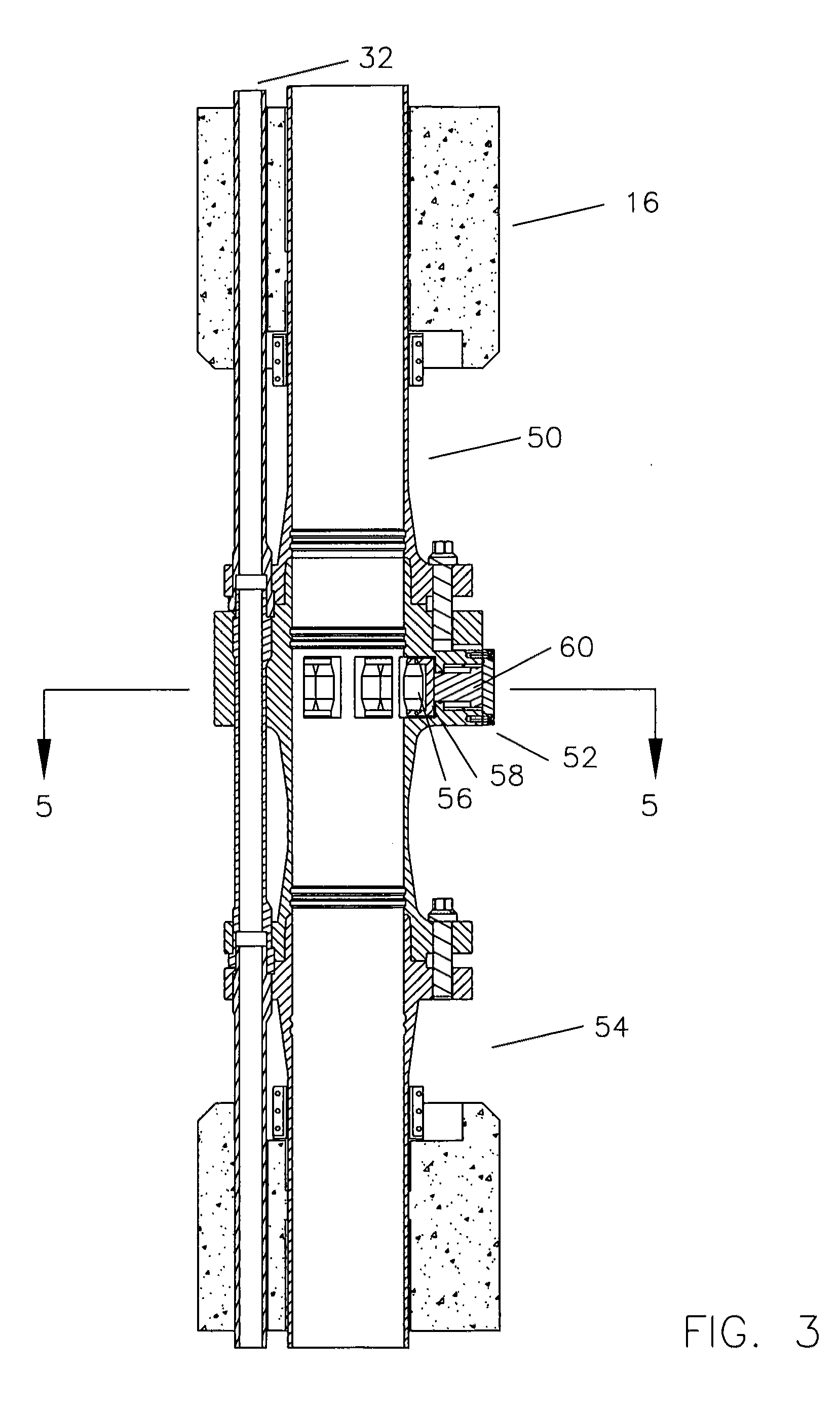

[0022]Referring now to FIG. 3, the section of drilling riser 16 shown comprises an upper riser joint 50, a drilling riser centralizer 52 and a lower riser joint 54. There is an upper bolted connection 56 between upper riser joint 50 and drilling riser centralizer 52 and a lower bolted connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com