Workpiece supply device

A technology for supplying devices and workpieces, applied to spraying devices, etc., can solve problems such as paint waste, and achieve the effect of shortening the coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

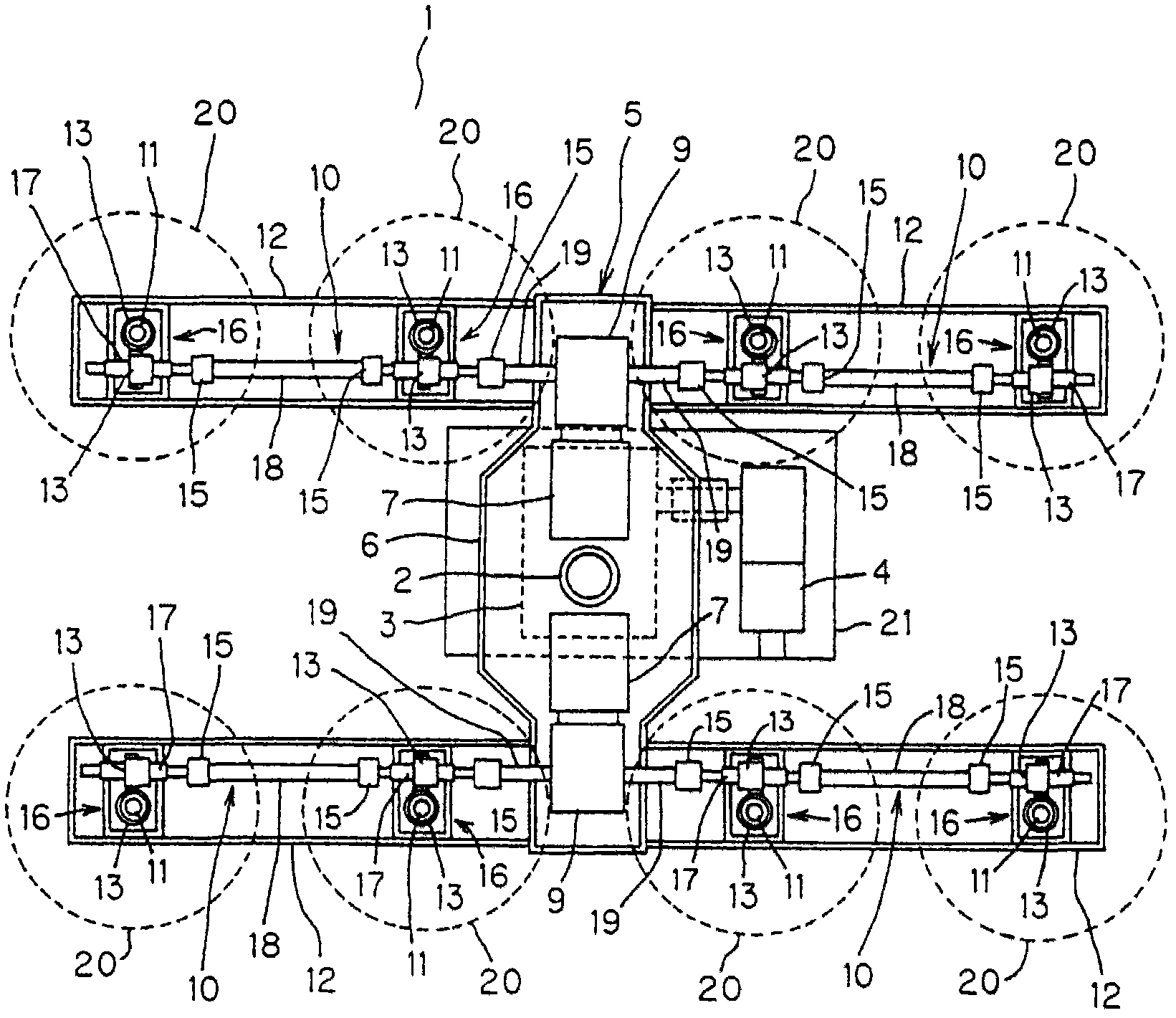

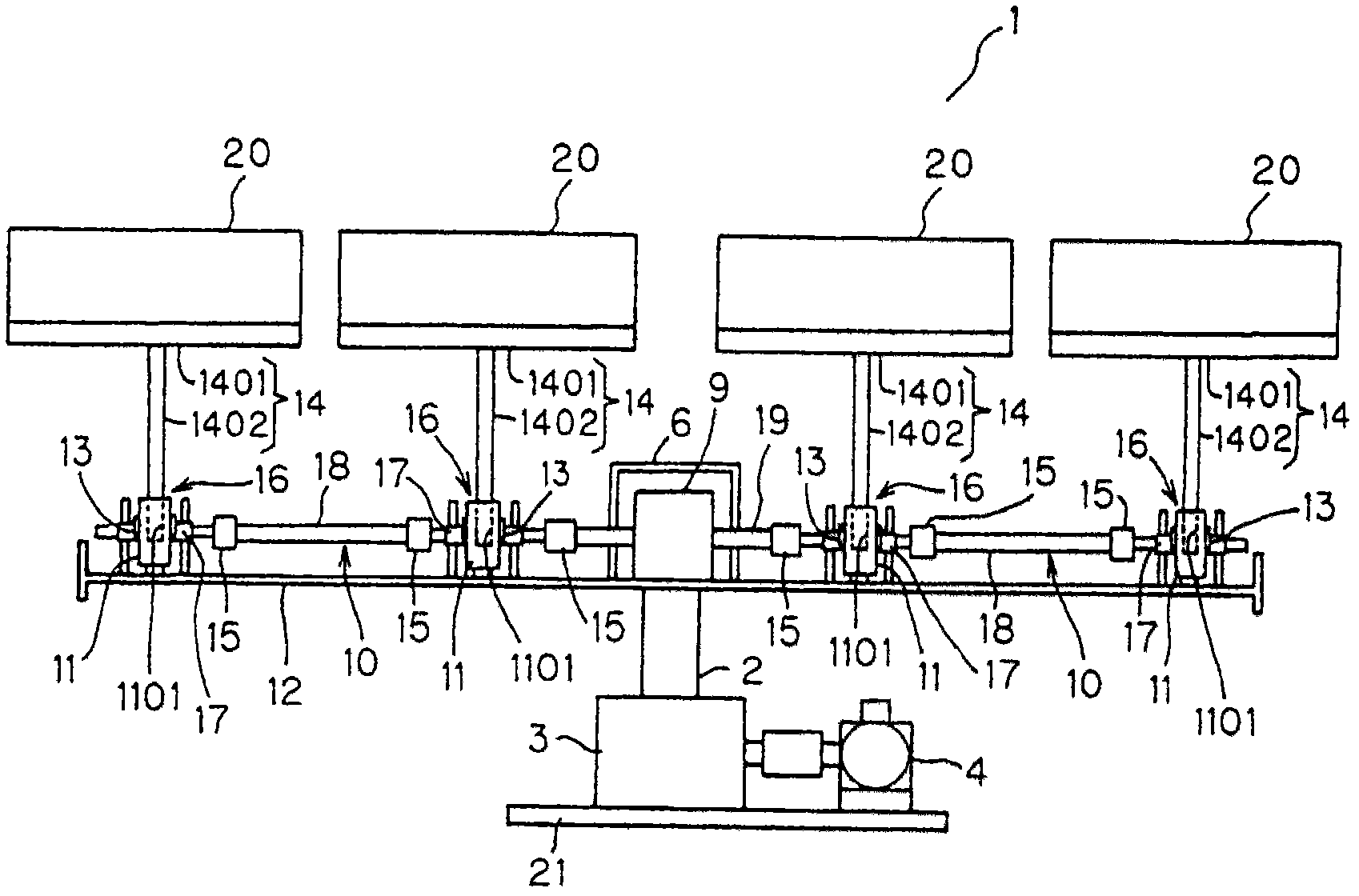

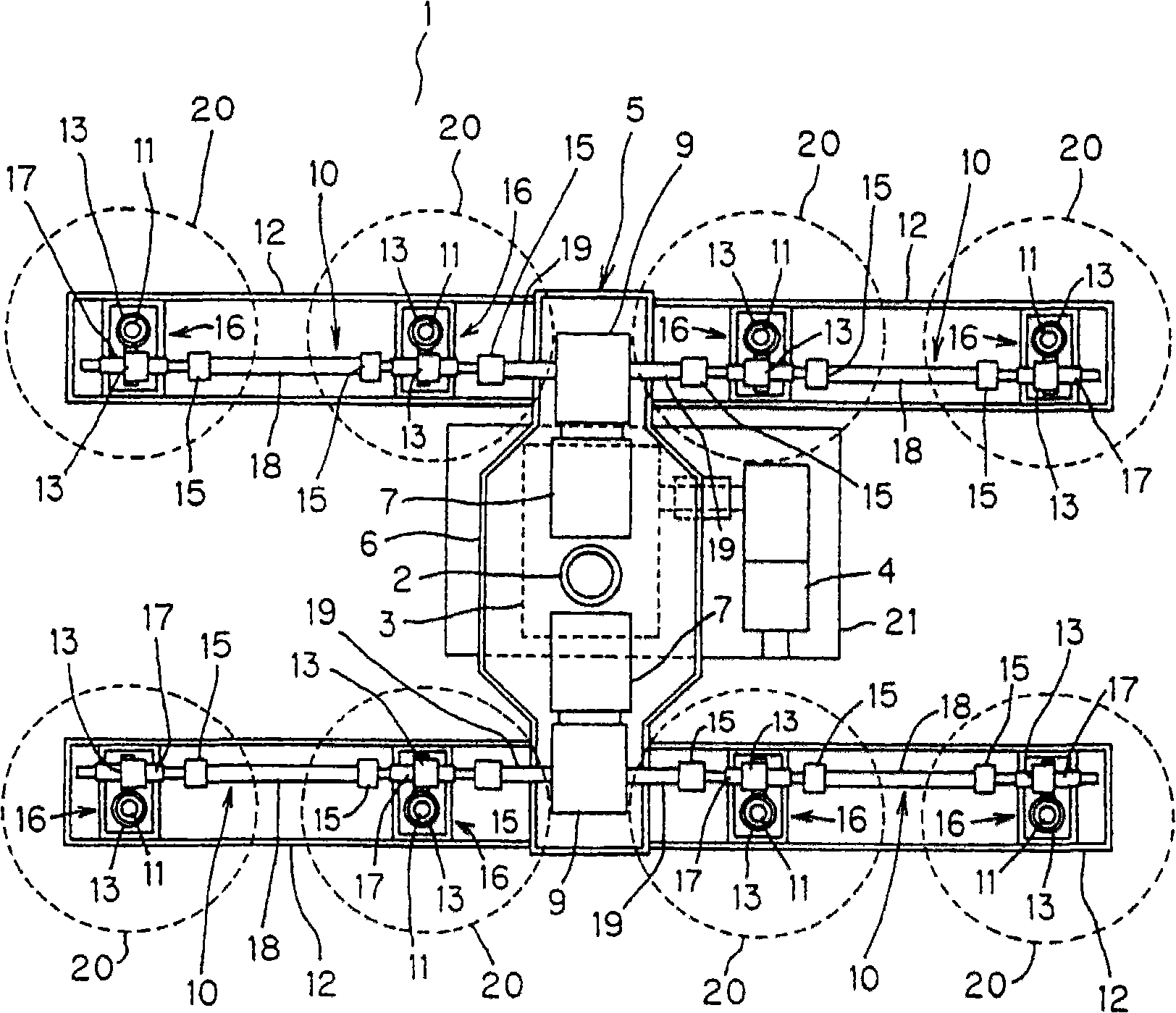

[0052] Embodiments of the workpiece supply device of the present invention will be described with reference to the drawings, figure 1 is a view showing the configuration of the workpiece supply device of this embodiment from the plane side, figure 2 is a view showing the configuration of the workpiece supply device of this embodiment from the front side, and in the view, 1 is the workpiece supply device of this embodiment.

[0053] In addition, in the drawing, 20 is a workpiece attached to the workpiece supply device 1 of the present embodiment, and in the present embodiment, the workpiece is a wheel for an automobile.

[0054] Next, in the view, 2 is the main axis. That is, the workpiece supply device 1 in this embodiment has a main shaft 2. In this embodiment, the main shaft 2 is rotatably supported by a mounting base 21 through a rotating mechanism. Wait on the ground.

[0055] Moreover, in this embodiment, the above-mentioned rotating mechanism is an indicator device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com