Mask developing method and apparatus

A development method and a technology of a development device, which are applied in the field of mask development, can solve the problems that the uniformity of the development line width is greatly affected, and the uniformity of the width of the developer solution is poor, so as to shorten the coating time, improve the uneven coverage, and improve Effect of Line Width Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

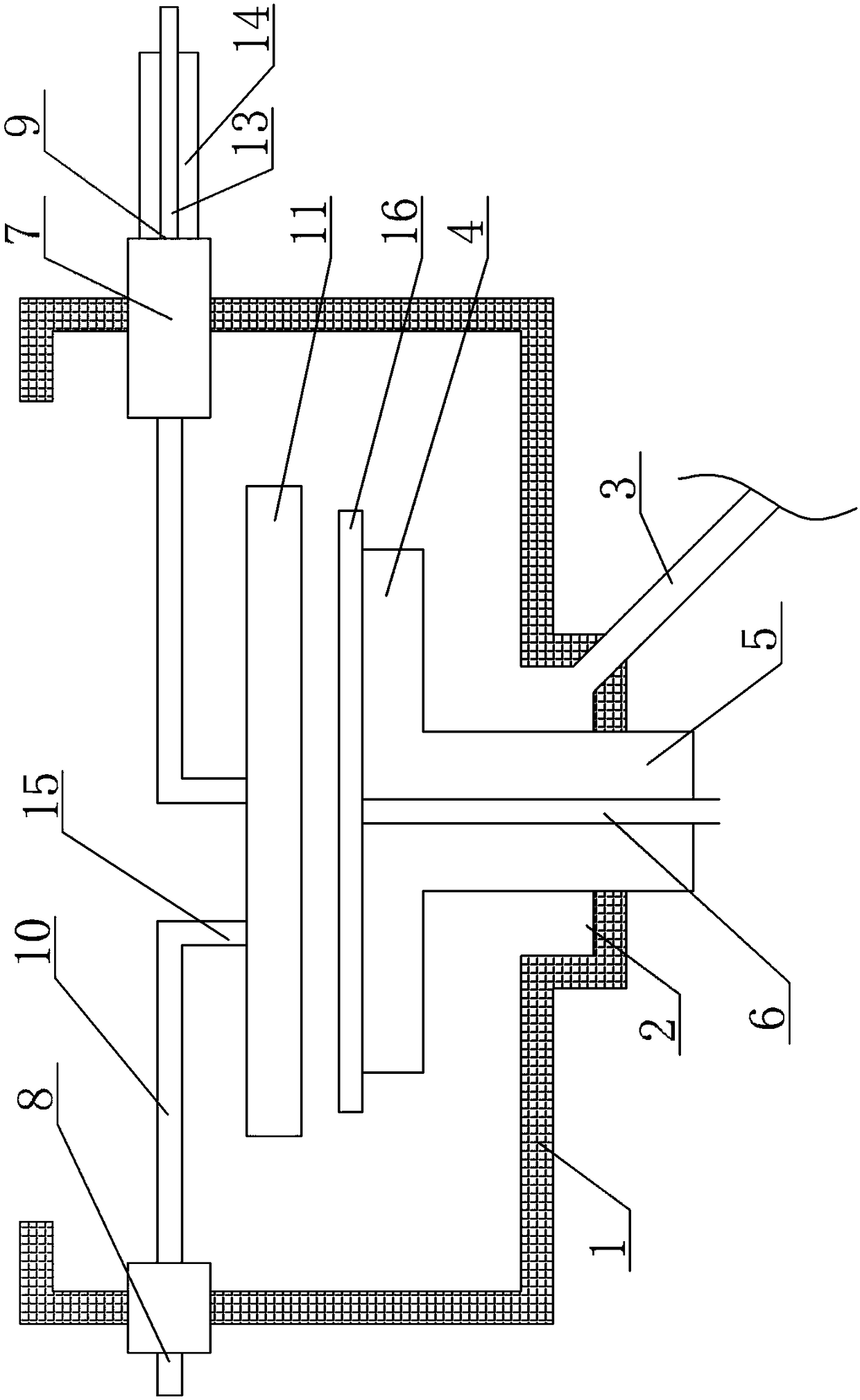

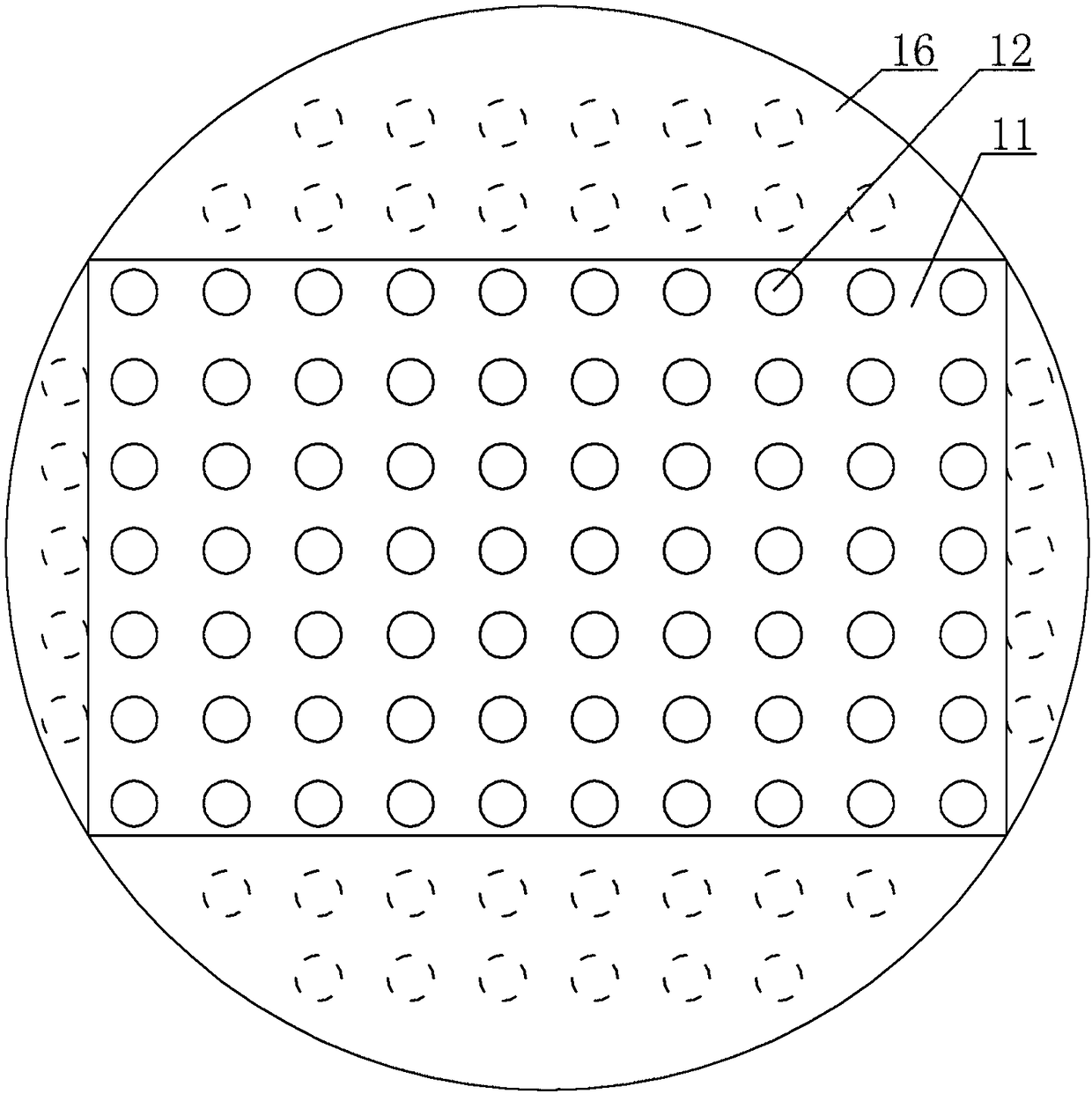

[0021] A method for developing a mask: a developing nozzle is arranged directly above a circular carrying platform, the cross section of the developing nozzle is in a rectangular shape, the length of the diagonal of the developing nozzle is not less than the diameter of the circular carrying platform, and the developing The nozzles are arranged horizontally parallel to the circular bearing platform, and the lower end surface of the developing nozzle is evenly distributed with spray holes arranged in a rectangular array, and the spray holes are arranged vertically downwards, and the mask is fixed on the upper surface of the bearing platform, and the bearing platform is driven While rotating, the developing nozzle pumps the developing solution through the liquid pump and covers the area corresponding to the lower mask through the spray hole. During the rotation of the mask, the developing solution evenly covers the center and edge of the mask.

[0022] The area center of the deve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com