Method for improving coating uniformity of release agent by using nano coating

A technology of nano-coating and mold release agent, which is applied in the direction of coating, metal material coating process, sputtering plating, etc. Reduced precision and other issues, to achieve the effect of simple implementation, optimized demolding quality, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

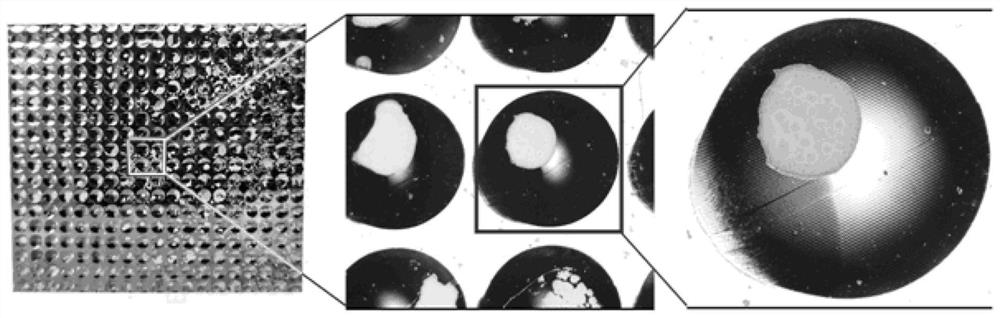

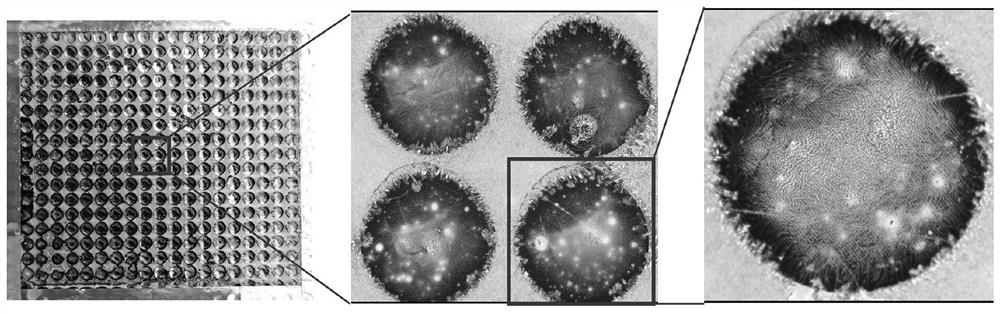

[0021] Preparation of potassium dichromate release agent solution: according to figure 1 Medium lens structure surface area, weigh 5g of potassium dichromate, temperature 20°C, add 100mL of deionized water into the beaker, stir well, and let stand for 1h.

[0022] Pretreatment of the copper mold: activate the copper mold with acetic acid, degrease with acetone, rinse with deionized water, and air dry.

[0023] The production of Cr coating: put the cleaned copper mold into the sputtering chamber of the magnetron sputtering instrument (the model can be VTC-600-3HD), close the valve, open the chiller and the control panel, and start the mechanical pump. Vacuumize, adjust the power of the DC power supply to 150W, the time is 15s, adjust the heating temperature of the control panel substrate to 35°C, the rotational speed of the sample stage to 12rpm, the argon flow rate to 35sccm, and use the quartz crystal film thickness monitor attached to the magnetron sputtering instrument (Qu...

Embodiment 2

[0026] Preparation of potassium dichromate release agent solution: according to figure 1 Medium lens structure surface area, weigh 8g of potassium dichromate, temperature 25°C, add 100mL of deionized water into the beaker, stir well, and let stand for 1h.

[0027] Pretreatment of the copper mold: activate the copper mold with acetic acid, degrease with acetone, rinse with deionized water, and air dry.

[0028] Production of Cr coating: Put the cleaned copper mold into the sputtering chamber of the magnetron sputtering instrument (model VTC-600-3HD), close the valve, open the chiller and control panel, and start the mechanical pump for vacuuming , adjust the power of the DC power supply to 200W, the time to 18s, adjust the heating temperature of the control panel substrate to 40°C, the rotational speed of the sample stage to 16rpm, and the argon flow rate to 40sccm, and use the quartz crystal film thickness monitor (Quartz Crystal Microbalance, referred to as QCM, can use the ...

Embodiment 3

[0031] Preparation of potassium dichromate release agent solution: according to figure 1 Medium lens structure surface area, weigh 10g of potassium dichromate, temperature 30°C, add 100mL of deionized water into the beaker, stir well, and let stand for 1h.

[0032] Pretreatment of the copper mold: activate the copper mold with acetic acid, degrease with acetone, rinse with deionized water, and air dry.

[0033] Production of Cr coating: Put the cleaned copper mold into the sputtering chamber of the magnetron sputtering instrument (model VTC-600-3HD), close the valve, open the chiller and control panel, and start the mechanical pump for vacuuming , adjust the power of the DC power supply to 250W, the time to 20s, adjust the substrate heating temperature of the control panel to 45°C, the rotational speed of the sample stage to 20rpm, and the argon gas flow rate to 45sccm, and use the quartz crystal film thickness monitor (Quartz Crystal Microbalance, QCM for short, model EQ-TM1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com