Method for bonding optical substrate and carrier plate and process for manufacturing soft substrate by method

A flexible substrate and optical technology, used in chemical instruments and methods, semiconductor/solid-state device manufacturing, lamination devices, etc., can solve problems such as yield decline, affecting process, and reduce equipment costs and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable your examiner to clearly understand the content of the present invention, the following descriptions are provided together with the drawings, please refer to them.

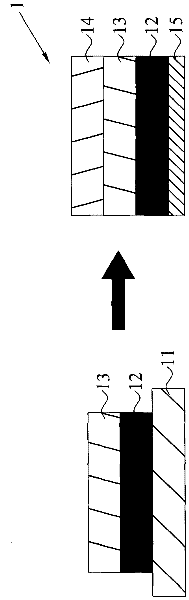

[0033] see Figure 5 As shown, it is a flowchart of a preferred embodiment of the method for laminating an optical substrate and a carrier plate according to the present invention, which includes the following steps

[0034] S11: Provide an optical substrate.

[0035] S12: Provide a solid silica gel layer, which has an electrostatic adsorption force.

[0036] S13: disposing the solid silica gel layer on the optical substrate by electrostatic adsorption.

[0037] S14: Provide a carrier board.

[0038] S15: placing the carrier plate on the solid silica gel layer by electrostatic adsorption.

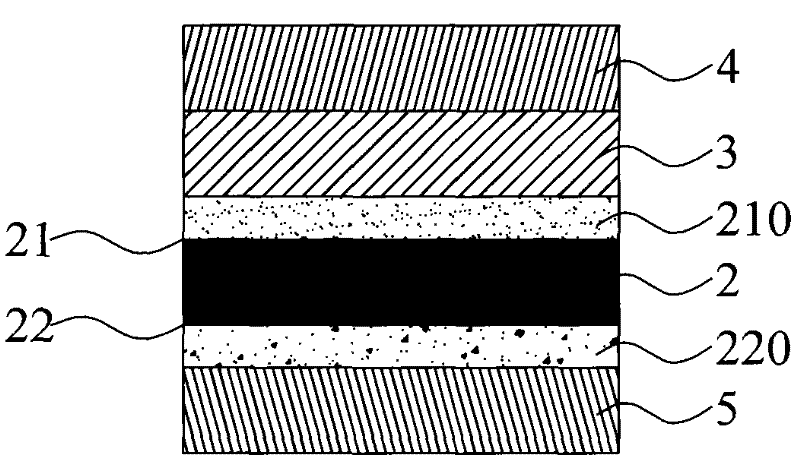

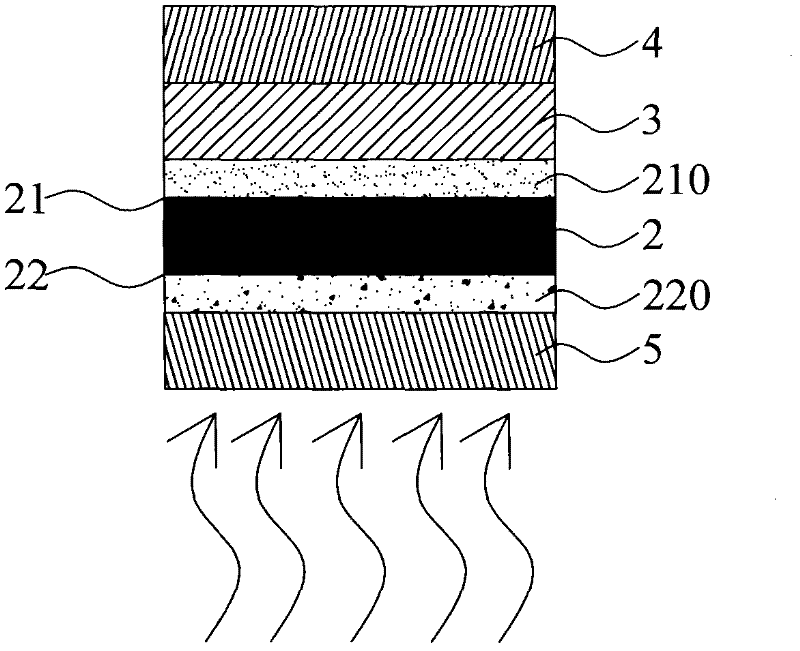

[0039] Please also refer to Figure 6 , which is a schematic diagram of a preferred embodiment of the method for laminating an optical substrate and a carrier in the present invention.

[0040] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com