Method for preparing high-activity corn antihypertensive peptide

A blood pressure-lowering peptide, high-activity technology, applied in the field of natural product preparation, to achieve the effect of reducing adverse effects, significant blood pressure lowering effect, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, preparation process embodiment

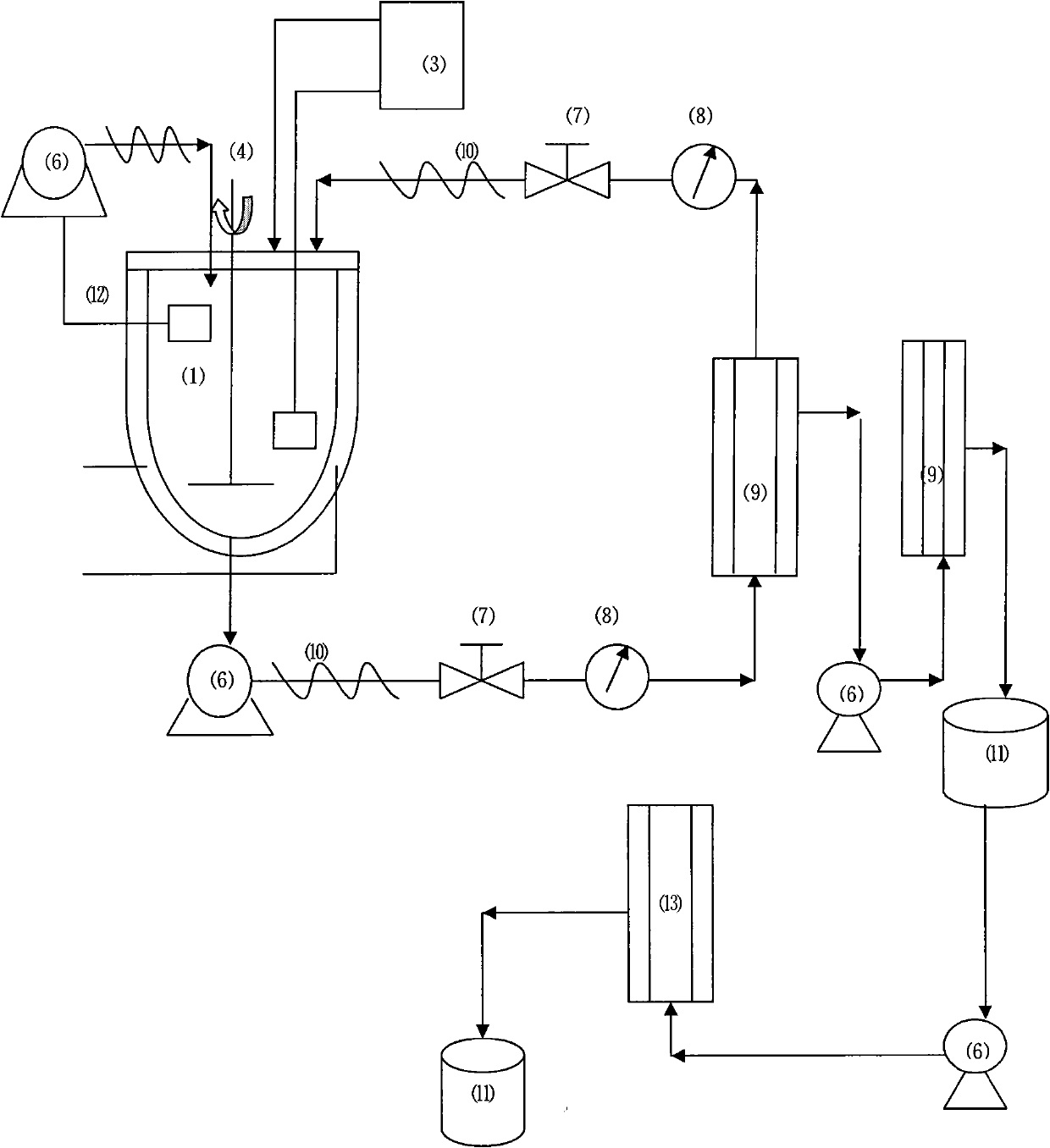

[0040] Experimental setup for hydrolysis of zein in an enzyme membrane reactor such as figure 1 shown.

[0041] Depend on figure 1 , the special device of the present invention is a continuous treatment enzyme membrane reaction system, which includes a reaction tank 1, temperature control system 2, automatic pH titrator 3, strong stirrer 4, feed liquid storage tank 5, peristaltic pump 6, Control valve 7, pressure gauge 8, ultrafiltration membrane assembly 9, pipeline heat exchanger 10, collection tank 11, liquid level controller 12 and nanofiltration membrane assembly 13 constitute, wherein said reaction tank 1 and temperature control system 2, The automatic pH titrator 3 and the strong agitator 4 form a circulating reaction system. The reaction tank 1 is installed at a horizontal position higher than the ultrafiltration membrane module 9 in the installation position, and one end thereof passes through the peristaltic pum...

Embodiment 2

[0064] Embodiment 2 Drying embodiment of corn hypotensive peptide of the present invention

[0065] 1 Experimental method

[0066] 1.1 Freeze-drying of corn hypotensive peptide solution

[0067] The corn hypotensive peptide solution obtained in Example 1 was vacuum-concentrated to 1 / 10 of its original volume at a temperature of 45° C. and a pressure of 0.095 MPa, placed in a stainless steel tray with a liquid level of 2 cm, and pre-cooled in a freeze dryer. After 120 minutes, when the temperature of the material reaches -20°C, it is completely frozen, and the temperature starts to rise. The vacuum degree is 0.040 mbar. The heating temperature starts from -20°C and rises slowly after 18 hours until the temperature reaches 25°C. Freeze dried.

[0068] 1.2 Spray drying of corn hypotensive peptide solution

[0069] The corn peptide solution obtained in Example 1 was vacuum-concentrated to 1 / 5 of its original volume at a temperature of 45° C. and a pressure of 0.095 MPa, and spr...

Embodiment 3

[0079] Example 3 Structural characterization and analysis of the corn hypotensive peptide prepared by the present invention

[0080] 1 Experimental method:

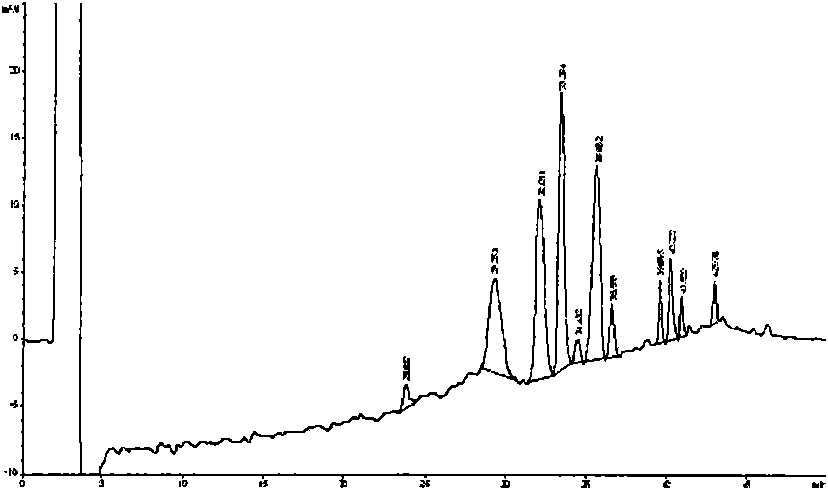

[0081] 1.1 Separation of corn hypotensive peptide by reversed-phase-high performance liquid chromatography (RP-HPLC)

[0082] The corn hypotensive peptide after ultrafiltration is analyzed by RP-HPLC, the conditions are as follows: Agilent 1200 high performance liquid chromatography, ZorbaxSB-C 18 5μm column, ID 4.6×250mm; mobile phase A is pure water + 0.1% trifluoroacetic acid, mobile phase B is acetonitrile + 0.1% trifluoroacetic acid; gradient elution: from 0 to 45min, mobile phase A is from 10% to 35%, the flow rate is 1.0mL / min; the ultraviolet detector detects at 230nm.

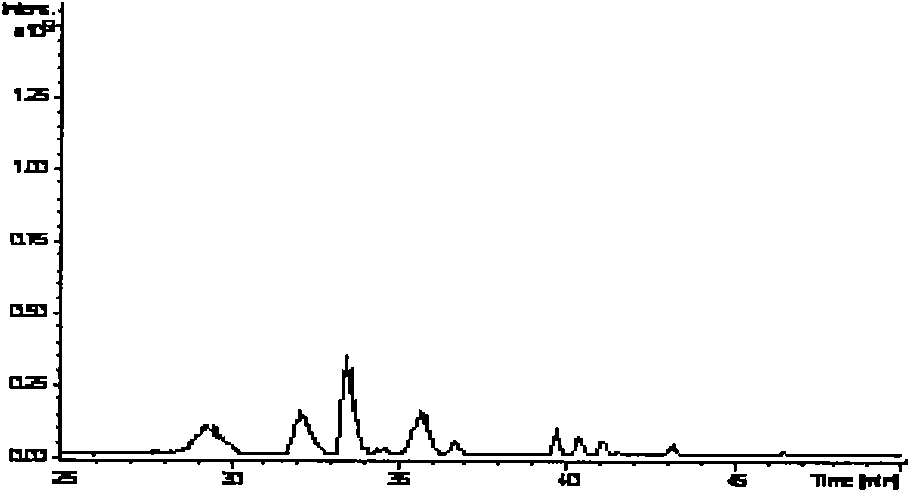

[0083] 1.2 High performance liquid chromatography-mass spectrometry / mass spectrometry (HPLC-MS / MS) analysis

[0084] Liquid chromatography conditions: Zorbax SB-C18 5μm column, ID 4.6×250mm; mobile phase A is pure water + 0.1% trifluoroacetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com