Detection jig for circular plastic product

A technology for detecting fixtures and products, applied in mechanical counters/curvature measurement, etc., can solve the problems of affecting product roundness accuracy, manufacturing scrap waste, uneven cooling shrinkage, etc., and achieve the effect of reducing product manufacturing costs and saving man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the embodiments and accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

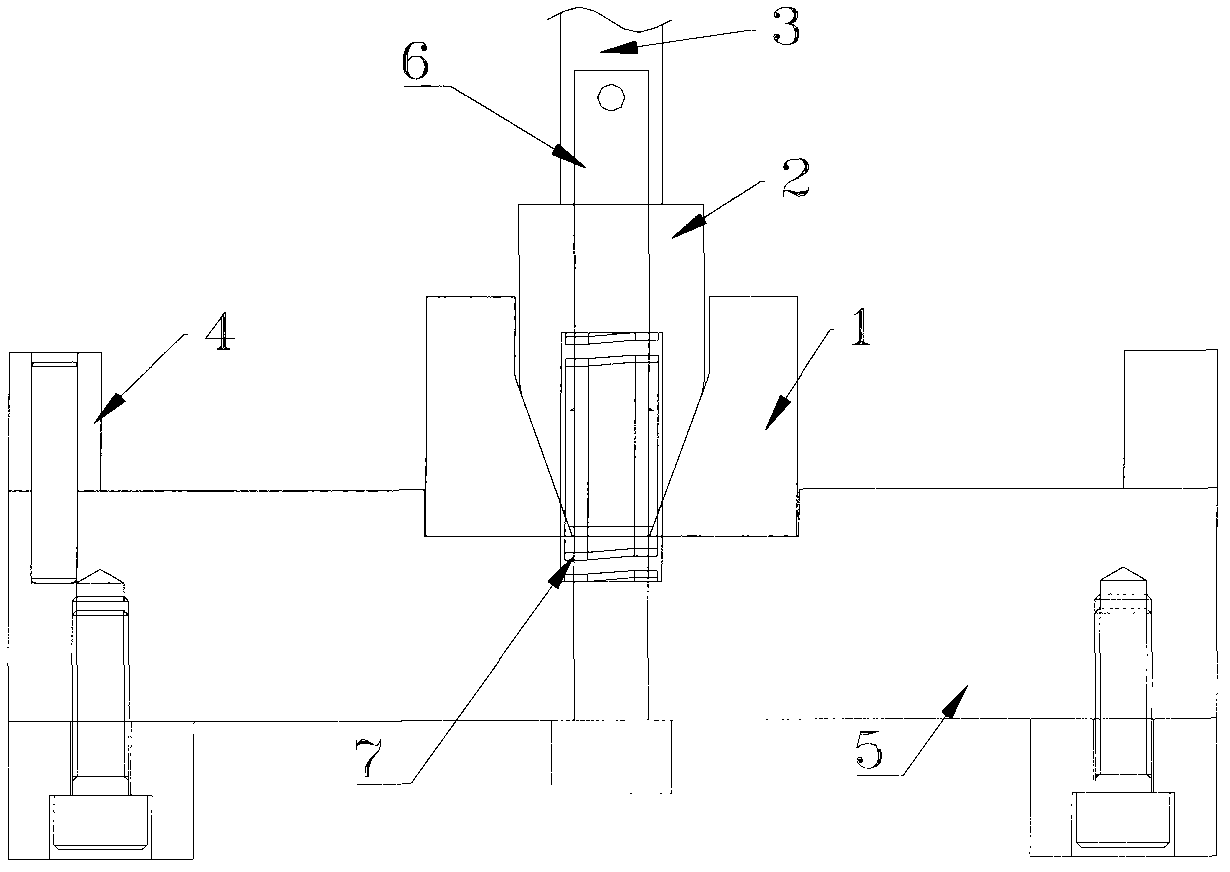

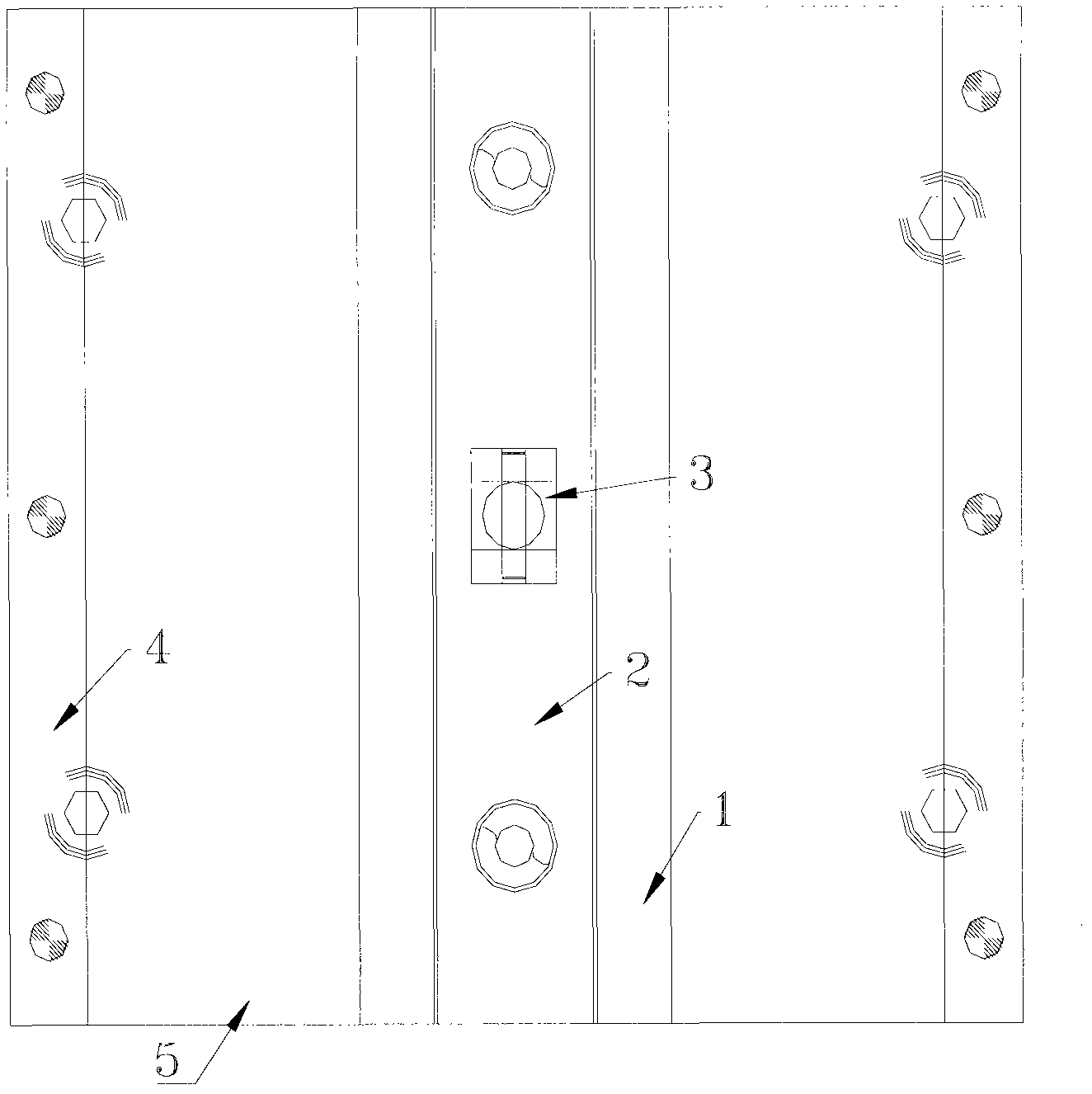

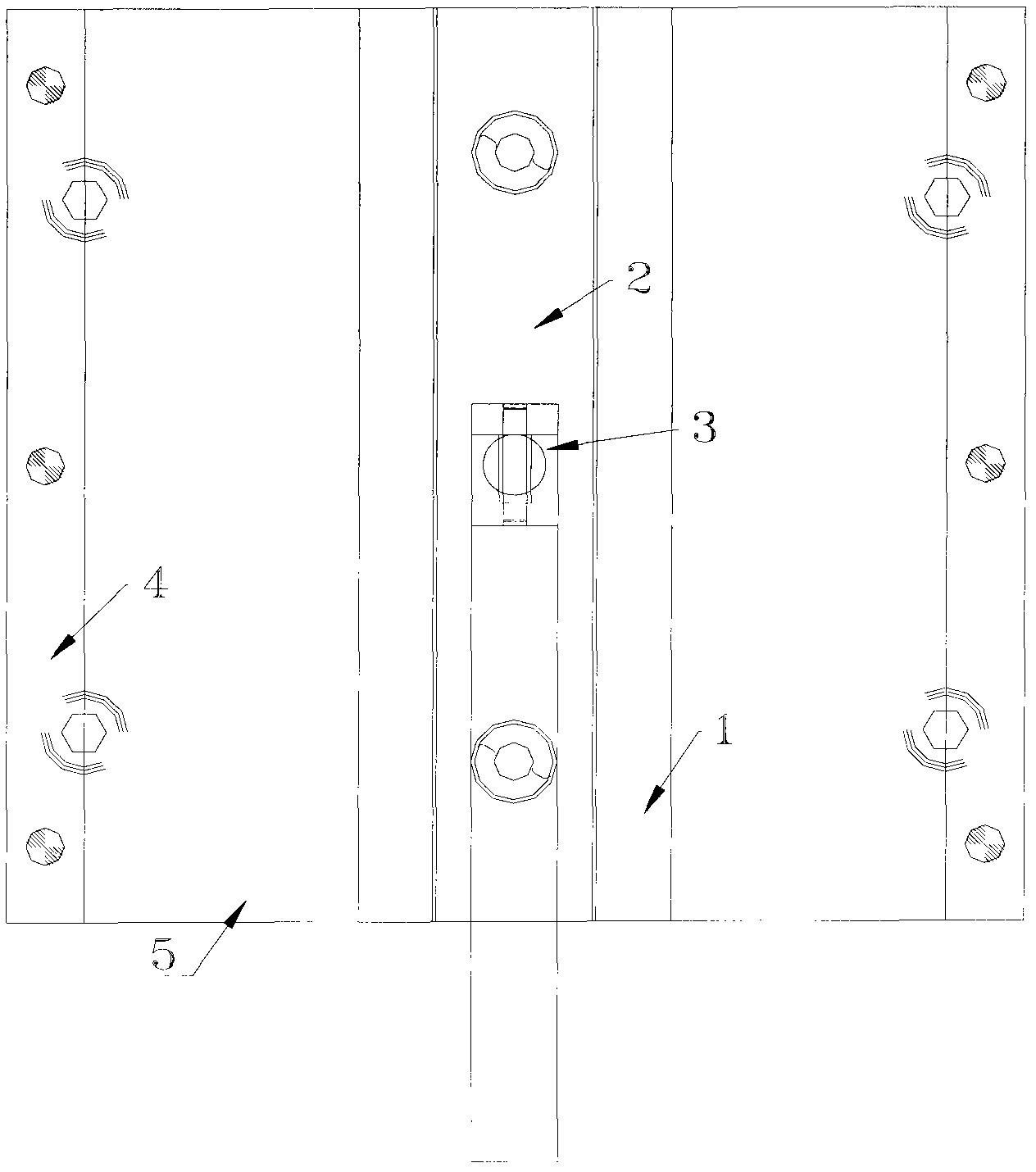

[0014] Such as figure 1 and figure 2 As shown, it is a schematic structural diagram of the detection fixture used for the manufacture of circular plastic products in the present invention. The illustration is only a single fixture unit in the detection fixture. In practical applications, the fixture unit It can also be arranged and combined in various ways (tied side by side) to form any scale of testing fixtures, and two adjacent fixture units can share a vertical baffle to simplify the testing fixtures. It can be seen from the cross-sectional schematic diagram in the width direction and the schematic structural diagram of the top view: the jig unit has a base 5 with vertical baffles 4 on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com