A multi-die synchronous roll forming method for large-diameter internal gear parts

A roll forming and multi-mold technology, which is applied to gears, household appliances, and other household appliances, can solve problems such as difficult roll forming of internal thread parts, high-strength impact toughness, and difficulty in ensuring force balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, a large-diameter internal tooth type multi-die synchronous roll forming method, comprising the following steps:

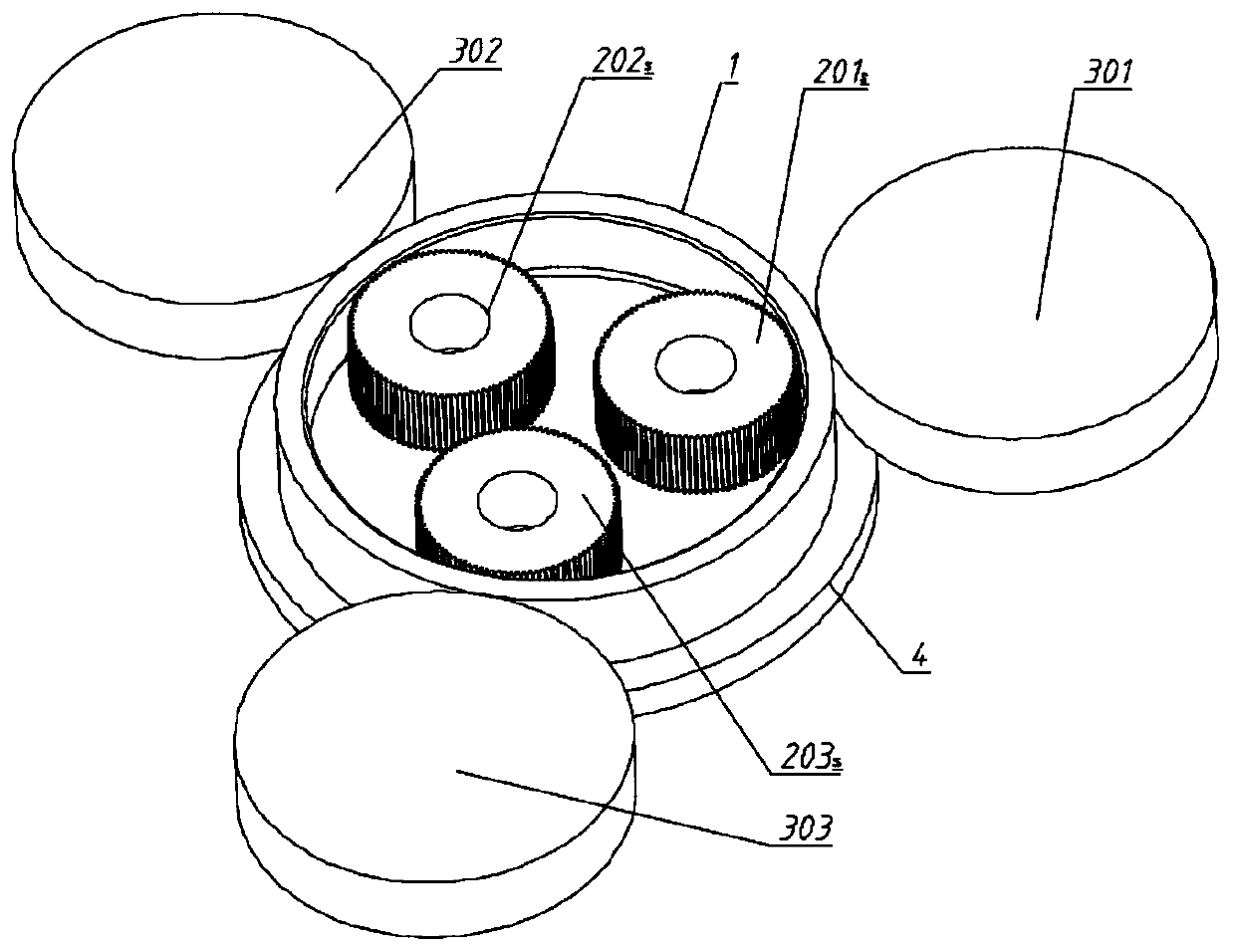

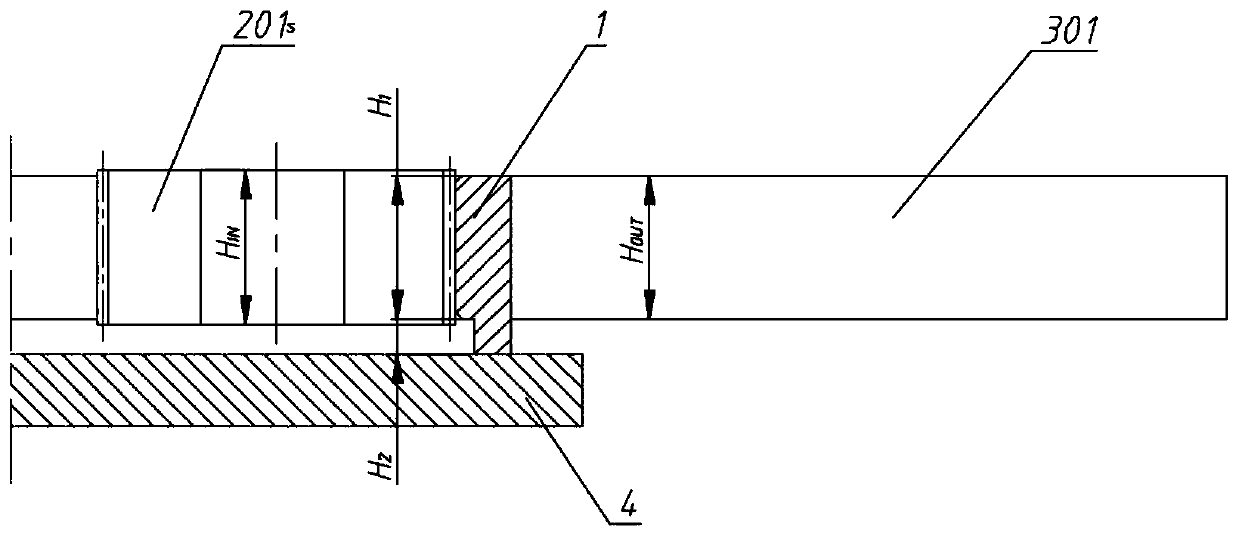

[0028] Step 1, refer to figure 1 and figure 2 , to clamp the workpiece blank 1, the workpiece blank 1 is driven by the turntable 4 (if the diameter is too large (greater than 5000mm), it can be driven by multiple double-toothed roller mechanisms), the central axis of the workpiece blank 1 and the central axis of the turntable 4 or evenly distributed The central axes of multiple double-toothed rollers coincide; the workpiece blank 1 is divided into a forming section and a clamping driving section in the axial direction, and its outer diameter is R b ;The forming section is the area where the inner tooth is formed, and the inner diameter is Height is H 1 , at the same time, in order to facilitate feeding and forming, both ends of the inner diameter are processed with chamfers L 1 ; There is no plastic deformation in the clamping drive secti...

Embodiment 2

[0037] Embodiment 2, a large-diameter internal tooth type multi-die synchronous roll forming method, comprising the following steps:

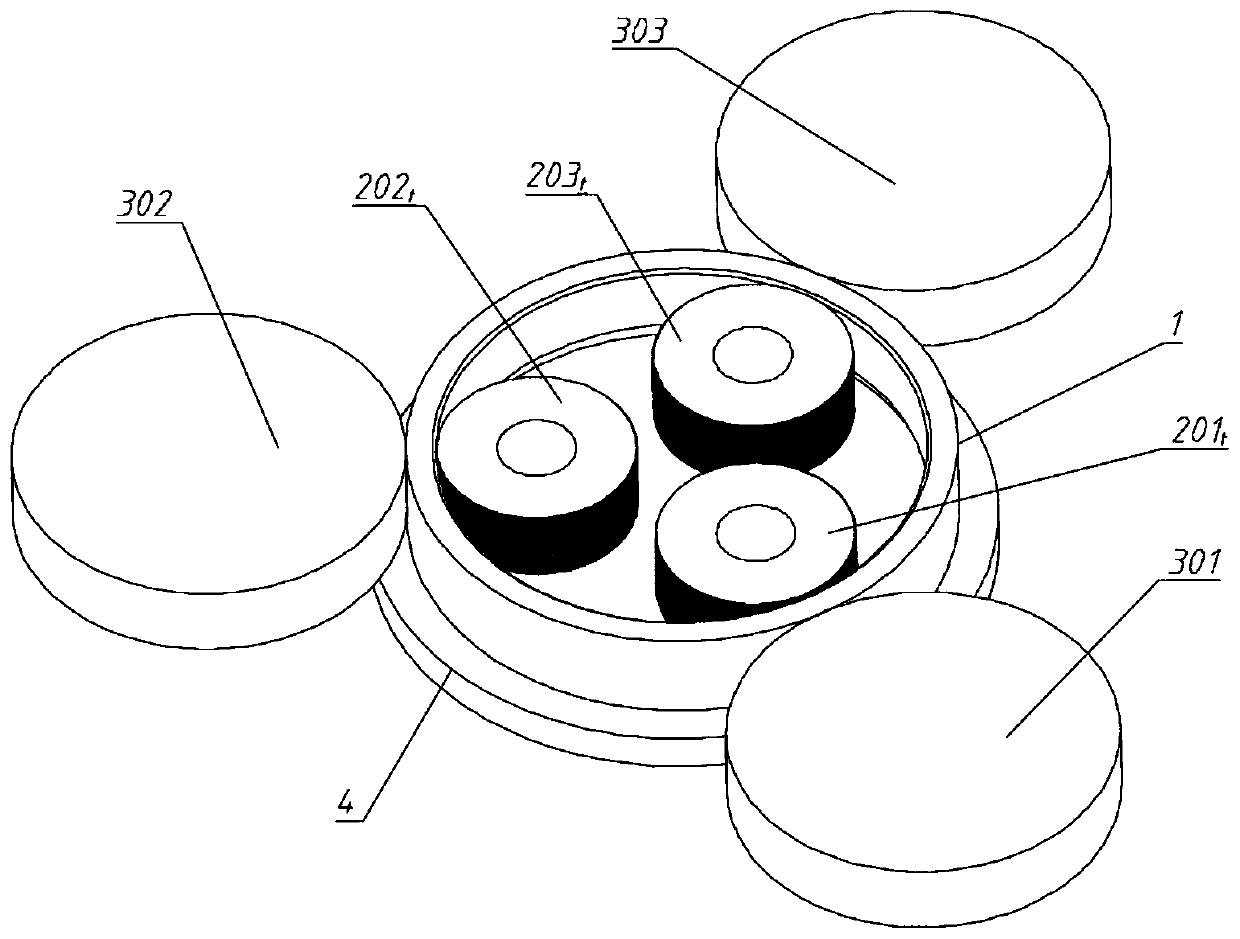

[0038] Step 1, refer to image 3 and Figure 4 , to clamp the workpiece blank 1, the workpiece blank 1 is driven by the turntable 4 (if the diameter is too large (greater than 5000mm), it can be driven by multiple double-toothed roller mechanisms), the central axis of the workpiece blank 1 and the central axis of the turntable 4 or evenly distributed The central axes of multiple double-toothed rollers coincide; the workpiece blank 1 is divided into a forming section and a clamping driving section in the axial direction, and its outer diameter is R b ;The forming section is the area where the inner tooth is formed, and the inner diameter is Height is H 1 , at the same time, in order to facilitate feeding and forming, both ends of the inner diameter are processed with chamfers L 1 ; There is no plastic deformation in the clamping drive secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com