On-site calibration equipment of integrated electric power voltage transformer

A technology for voltage transformers and on-site calibration, applied in instruments, measuring electrical variables, measuring devices, etc., can solve problems such as economic loss, heavy weight, time-consuming and labor-intensive, and achieve the effect of improving integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

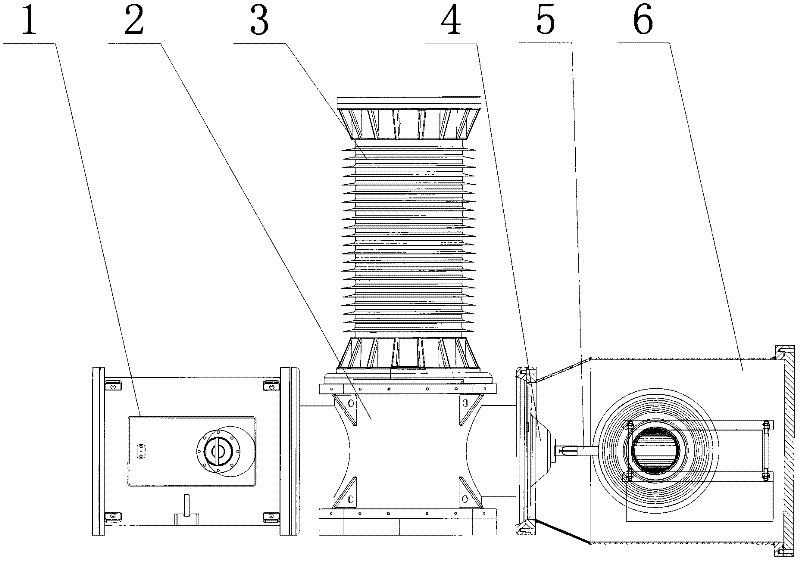

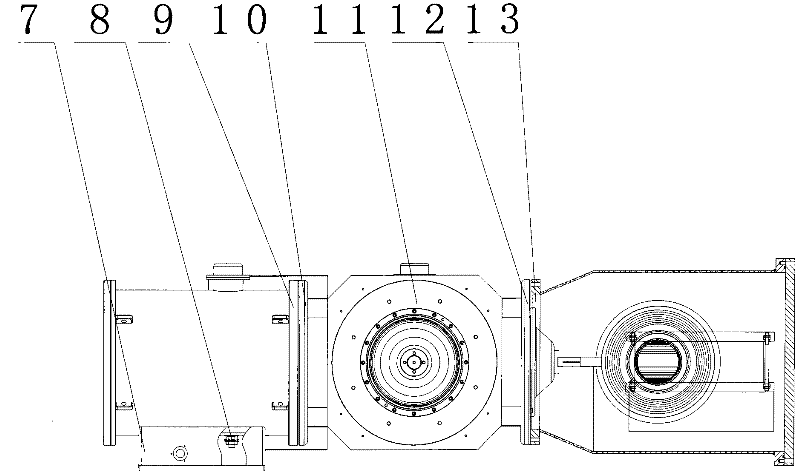

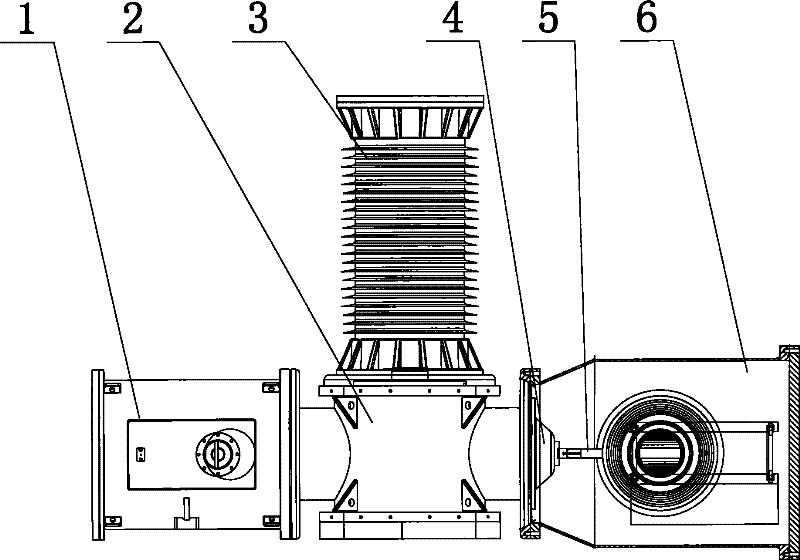

[0015] as attached figure 1 , 2 The shown integrated power voltage transformer field calibration equipment of the present invention includes a standard voltage transformer 1, an intermediate connecting cylinder 2, a high voltage bushing 3, a step-up test transformer 6, a first flange 9, Left flange 10, upper flange 11, right flange 12, second flange 13; the first flange 9 is set on the standard voltage transformer 1; the left flange 10 is set on the left side of the middle connecting cylinder 2 side interface; the right flange 12 is set at the interface on the right side of the middle connecting cylinder 2; the second flange 13 is set on the step-up test transformer 6; the upper flange 11 is set on the middle connecting cylinder 2; the first flange 9 is connected to the left flange 10; the second flange 13 is connected to the right flange 12; the high voltage bushing 3 is connected to the upper flange 11; the integrated power The voltage transformer on-site calibration equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com