Nonaqueous electrolyte secondary battery and method for manufacturing the same

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte batteries, electrolyte battery manufacturing, non-aqueous electrolyte battery electrodes, etc., to achieve excellent storage characteristics and reduce the initial defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

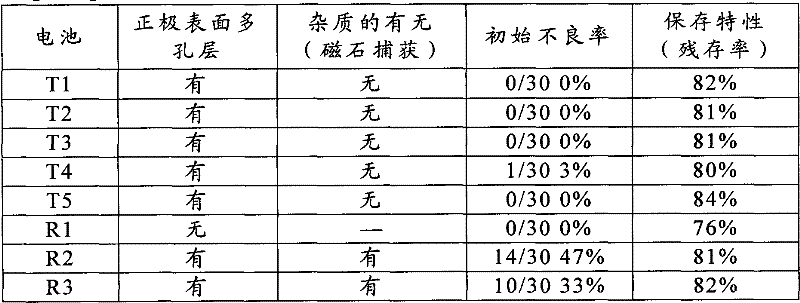

Examples

Embodiment 1

[0068] Formation of positive electrode active material layer

[0069] Lithium cobaltate, acetylene black as a carbon conductive agent, and PVDF (polyvinylidene fluoride) were mixed at a mass ratio of 95:2.5:2.5, and NMP was used as a solvent for mixing with a mixer to prepare positive electrode mixture slurry.

[0070] The prepared slurry was coated on both sides of an aluminum foil as a positive electrode current collector, dried and then rolled to form a positive electrode active material layer on the positive electrode current collector. In addition, the packing density of the positive electrode active material layer is 3.60 g / cm 3 .

[0071] Porous layer formation

[0072] As the inorganic particles contained in the porous layer, silica particles (SiO 2 , average particle size 40nm, surface area 50cm 2 / g, the trade name "AEROSIL50" manufactured by Aerosil Corporation of Japan, hydrophilic fumed silica). Moreover, the purity of the silica used is 99 mass % or more...

Embodiment 2

[0083] Silica particles (SiO 2 Average particle size: 20nm, surface area 90m 2 / g, the product name "AERO SIL90" manufactured by Japan AEROSIL Co., Ltd., hydrophilic fumed silica), and the aqueous slurry t2 and the battery T2 were produced in the same manner as in Example 1.

Embodiment 3

[0085] Silica particles (SiO 2 Average particle size: 16nm, surface area 130m 2 / g, the product name "AEROSIL30" manufactured by Japan AEROSIL Co., Ltd., hydrophilic fumed silica), and the aqueous slurry t3 and the battery T3 were produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap