Graphite material for negative electrodes of lithium secondary battery, manufacturing method for said material, and lithium secondary battery using same

A technology of graphite material and secondary battery, applied in secondary batteries, battery electrodes, graphite, etc., can solve the problems of increased reduction and decomposition of electrolyte, capacity deterioration, etc., and achieves inhibition of capacity deterioration, high reliability, and inhibition of capacity maintenance. rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

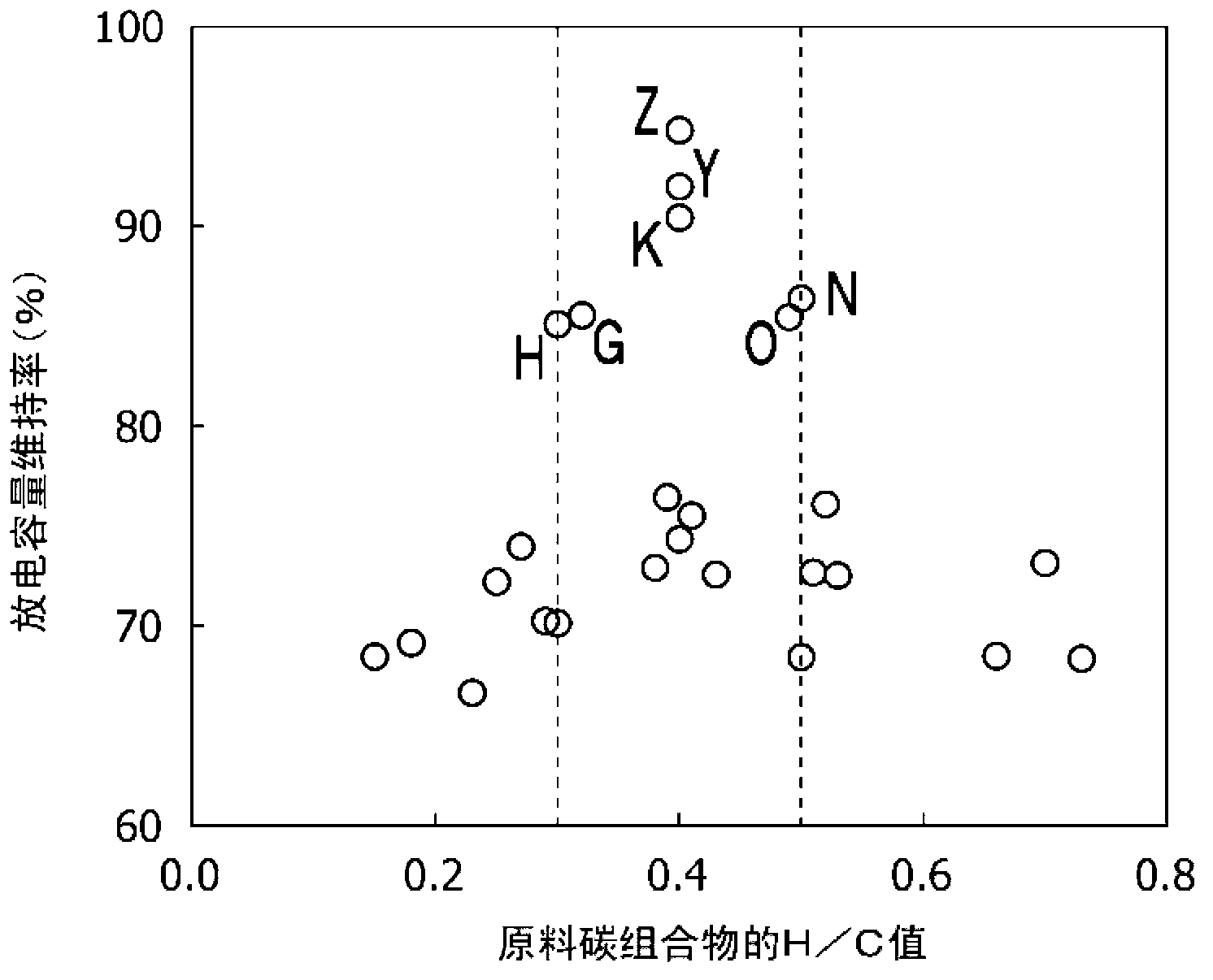

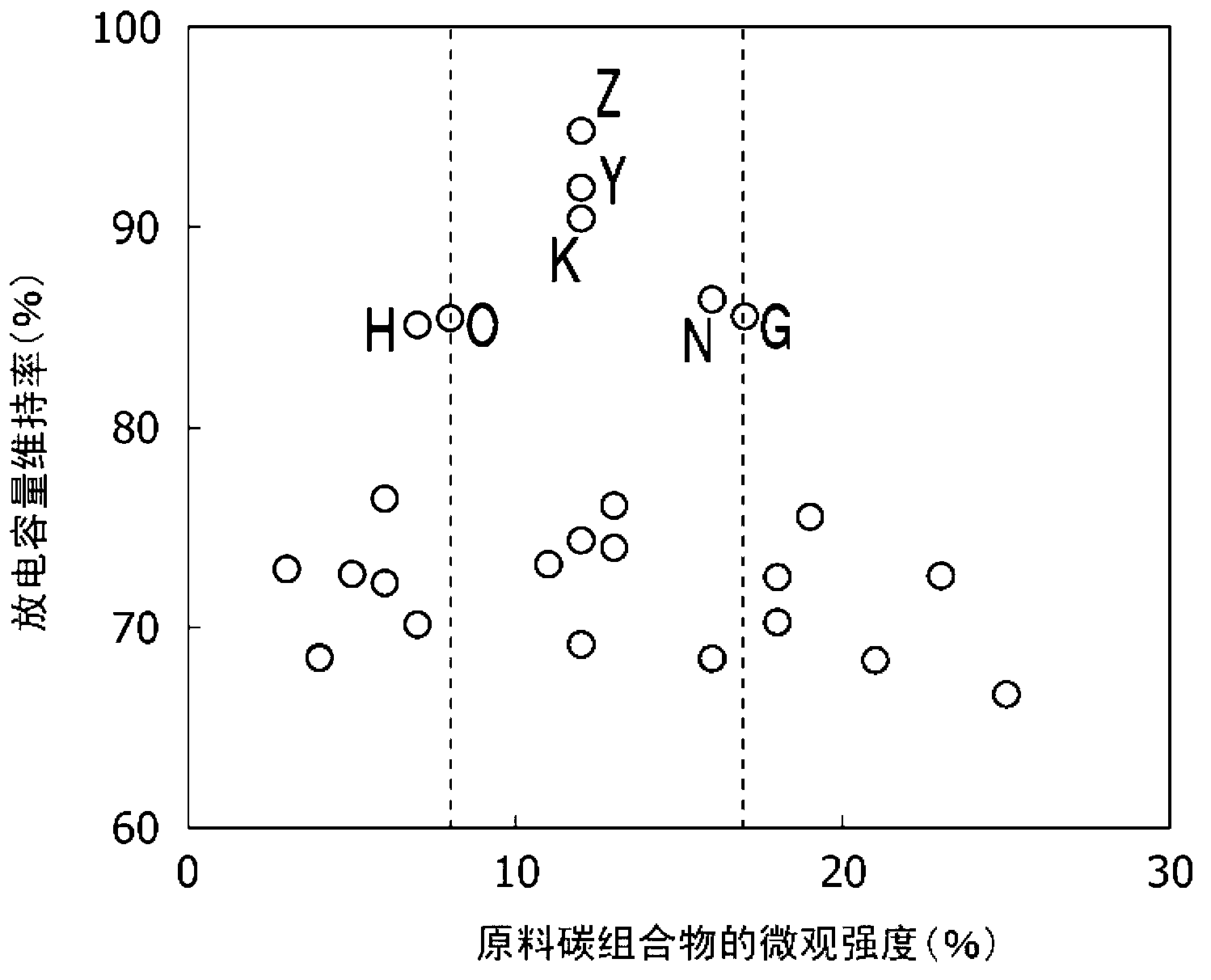

[0419] Hereinafter, based on examples and comparative examples, the first to third embodiments of the present invention will be described more specifically, but the present invention is not limited to the following examples.

[0420] 1. Raw material carbon composition and production method thereof

[0421] (1) Raw carbon composition A-1

[0422] Hydrodesulfurize the atmospheric distillation residue with a sulfur content of 3.1% by mass in the presence of a catalyst until the hydrocracking rate reaches 25% or less to obtain hydrodesulfurized oil. The hydrodesulfurization conditions are total pressure 180MPa, hydrogen partial pressure 160MPa, temperature 380°C. In addition, desulfurized vacuum light oil (with a sulfur content of 500 mass ppm and a density of 0.88 g / cm at 15°C 3 ) fluid catalytic cracking to obtain fluid catalytic cracking residue. The fluidized catalytic cracking residual oil is selectively extracted with dimethylformamide to be separated into aromatic compon...

Embodiment 1

[0648] In Examples 16 to 31 and Comparative Examples 19 to 46, the powders of raw carbon compositions A-3 to U-3 were mixed with calcined coke, and compressive shear stress was applied to obtain composite powders. Carry out carbonization and graphitization under the same conditions to obtain graphite material. Table 3 shows the average particle size of the calcined coke, the blending amount, and the conditions for applying compressive shear stress. Here, for Examples 16 to 28 and Comparative Examples 19 to 46, "NOBILTA Model 130" manufactured by HOSOKAWA MICRON CORPORATION was used as a device for applying compressive shear stress, and NIPPON COKE & ENGINEERING CO., LTD. was used in Examples 29 and 30. "COMPOSI CP-15" manufactured by HOSOKAWA MICRON CORPORATION and "Mechano Fusion AMS-Lab" manufactured by HOSOKAWA MICRON CORPORATION were used in Example 31. In addition, in Table 3, "NOBILTA130 type" is abbreviated as "N", "COMPOSI CP-15" is abbreviated as "C", and "Mechano Fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com