Branch fuel gas fire arrestor for inflammable gas collecting bag

A technology of flammable gas and gas collecting bag, applied in fire rescue and other directions, can solve problems such as hidden safety hazards and inability to cut off the gas source, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

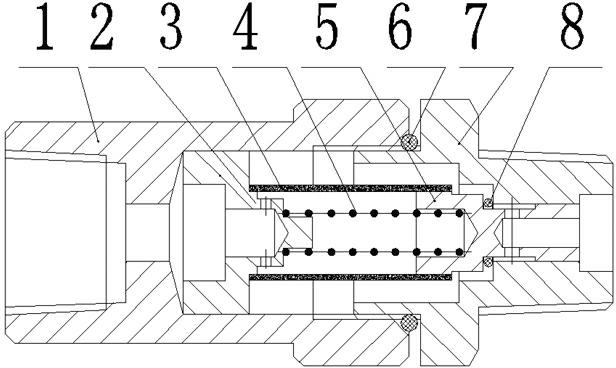

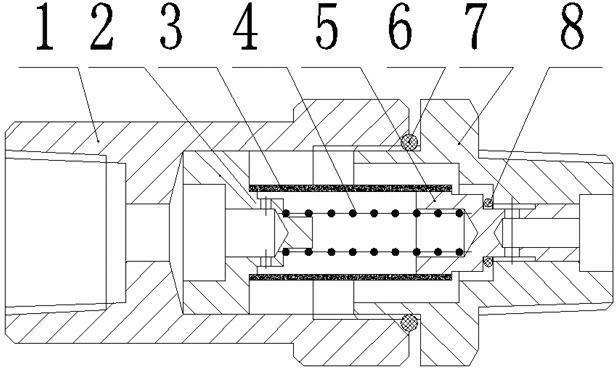

[0011] Such as figure 1 As shown, the present invention is a gas flame arrester for a branch pipeline of a flammable gas gas collection package, comprising: a housing 1, a spring seat 2, a fusible alloy microhole sleeve 3, a spring 4, a fixed sealing ring 6, a connector 7 and The movable sealing ring 8 is connected with a one-way valve core 5 on the spring 4, the spring seat 2 supports the spring 4 and the fusible alloy microhole sleeve 3, and the fixed sealing ring 6 is a static seal.

[0012] The action principle is: when the air is supplied normally, the pressure of the air source overcomes the spring force of the spring 4, and the one-way valve core 5 is opened to supply air to the designated place. When a tempering accident occurs, the heat of tempering melts the fusible alloy to block the micropores on the fusible alloy microporous sleeve 3, and the tempering is extinguished. The tempering heat causes the gas in the housing 1 to expand and the pressure to rise, pushing ...

Embodiment 2

[0014] It is the same as the gas flame arrester of the branch pipeline of the flammable gas gas collecting bag in the first embodiment, the difference is that: the check valve core 5 is also equipped with a movable sealing ring 8, and the movable sealing ring 8 is an intermittently working Static sealing, moving to connection 1 together with the one-way valve core 5, so that the fit is better, and the sealing and air shutoff are more thorough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com