T-shaped micropore spinneret plate

A spinneret and microporous technology, applied in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of fabric moisture absorption and air permeability that cannot meet market demand, achieve good moisture absorption and perspiration, and benefit the market The effect of promoting, improving quality and production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

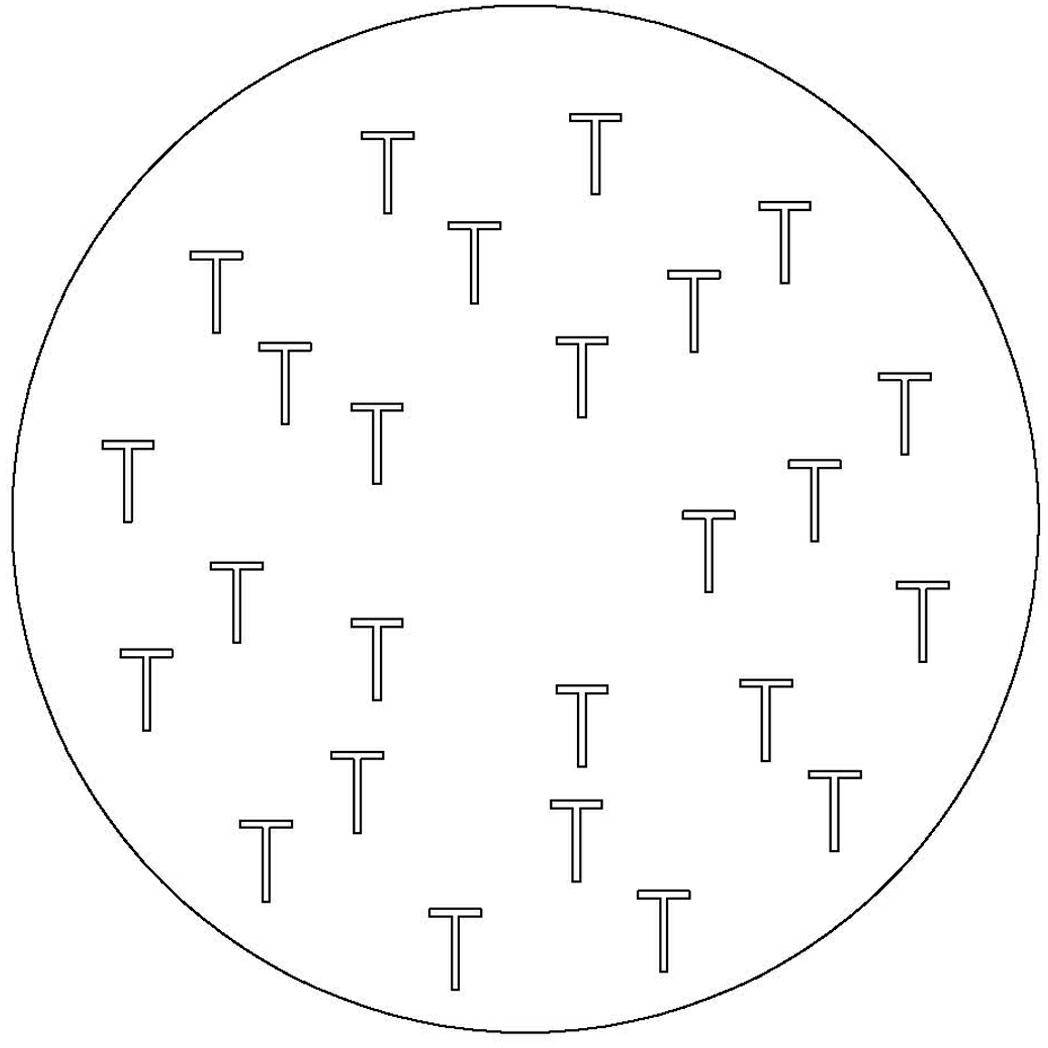

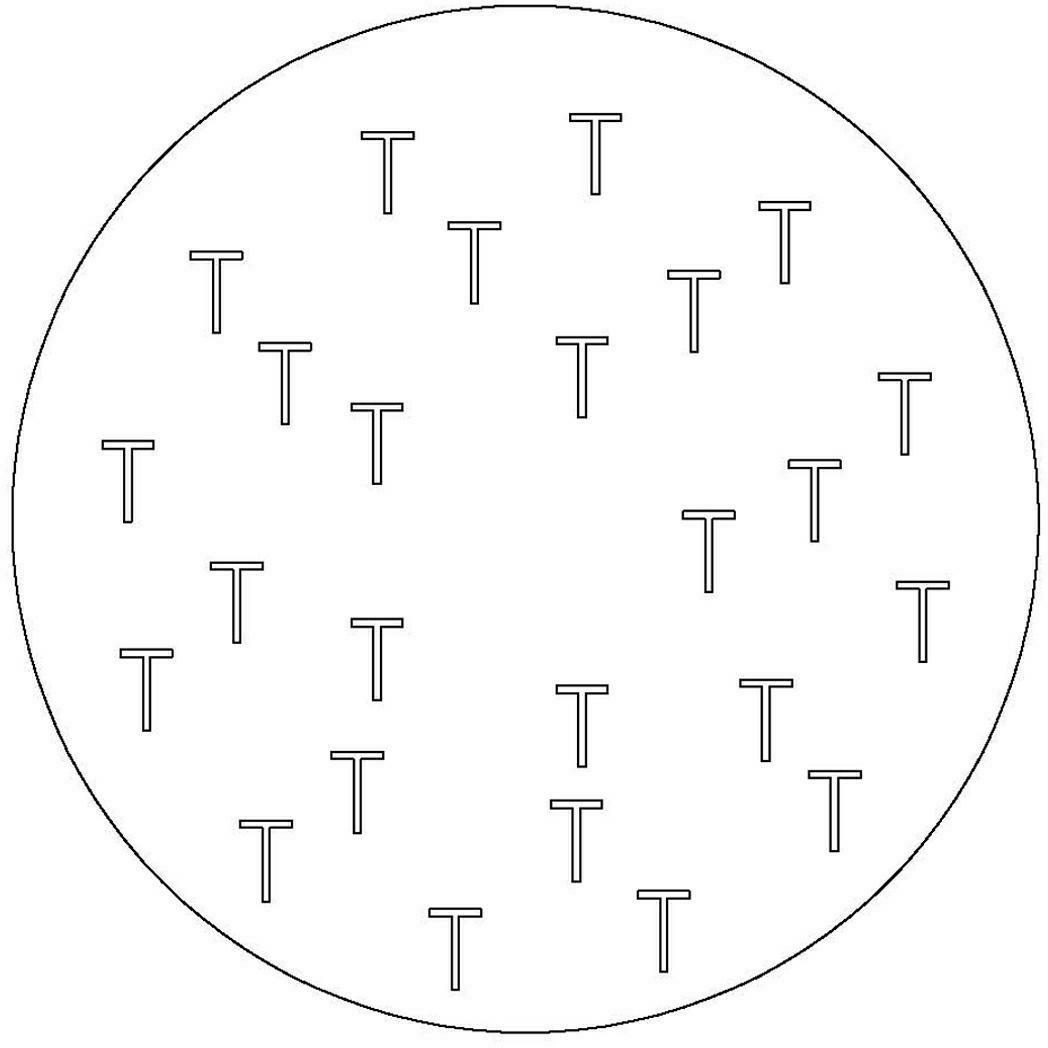

[0018] Such as figure 1 As shown, the diameter of the T-shaped micro-hole spinneret selected in the embodiment of the present invention is 70mm, and the spinneret holes on the spinneret adopt three circles to arrange, and the total number of three circles of spinneret holes is 25, starting from the innermost The first circle of layers is 5, the second circle is 8, and the third circle is 12; the width of the "T"-shaped transverse surface and longitudinal surface of the spinneret hole is 0.10-0.20mm; the "T" shape of the spinneret hole The ratio of the length and width of the ""-shaped transverse surface is 5-10, and the ratio of the length and width of the "T"-shaped longitudinal surface of the spinneret hole is 8-15. Due to the adoption of the "T"-shaped spinneret hole structure, the conventional cross-sectional shape is changed, so that the fiber cross-sectional shape of the produced polyester simulated filament is "T"-shaped. In addition to having a good moisture absorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com