Variable sound velocity water jet energy-saving device

An energy-saving device, water jet technology, applied in the direction of spraying device, spraying device, liquid spraying device, etc., to achieve the effect of compact and light device, small space occupation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

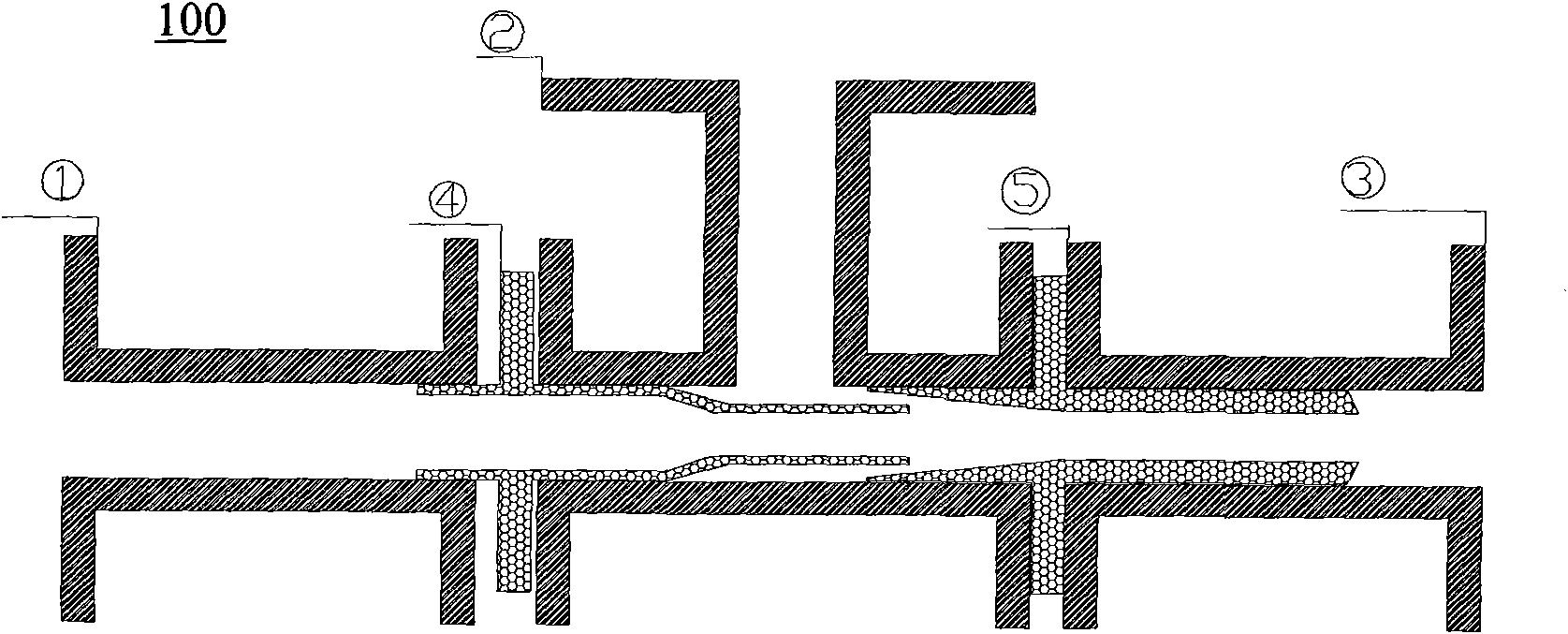

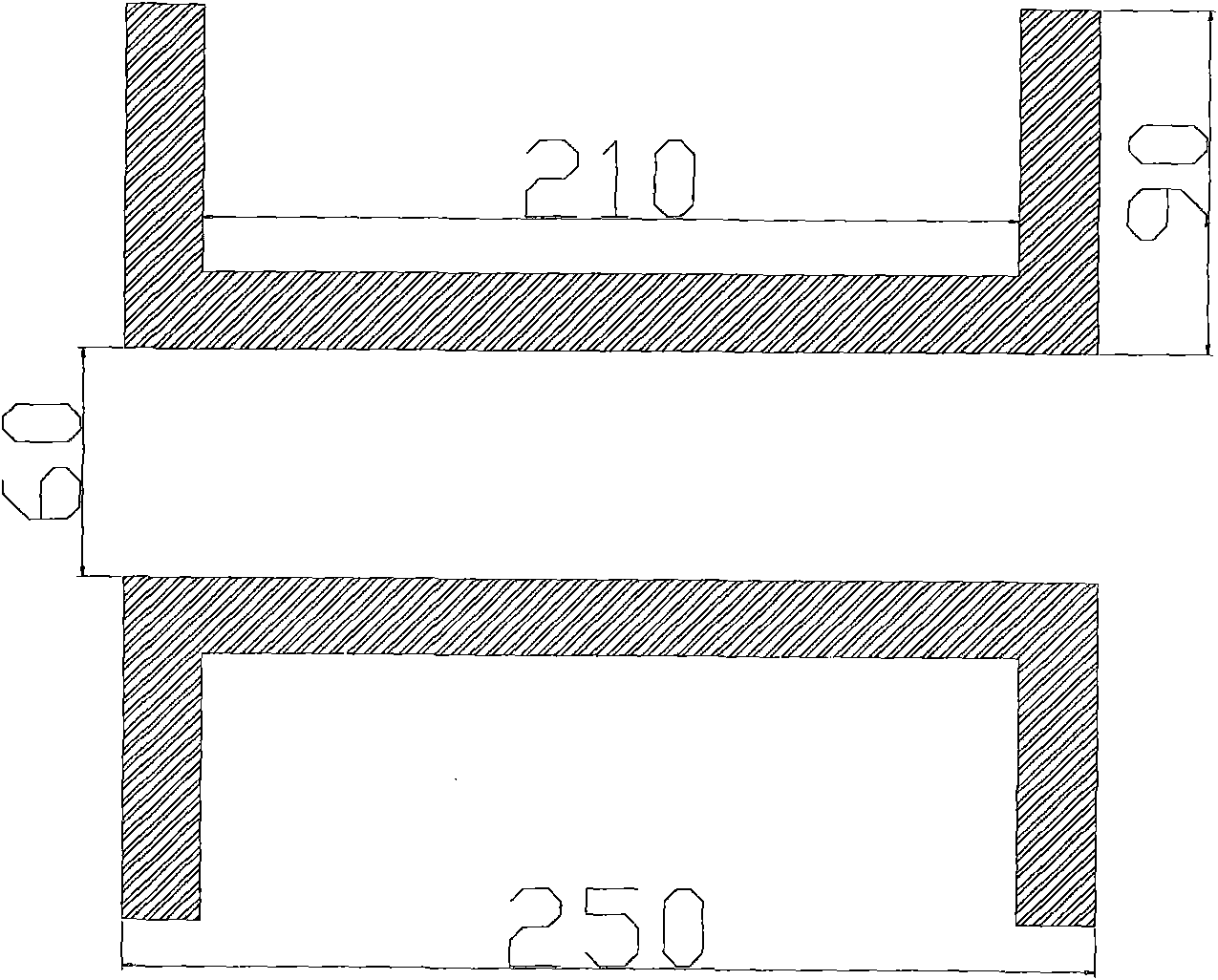

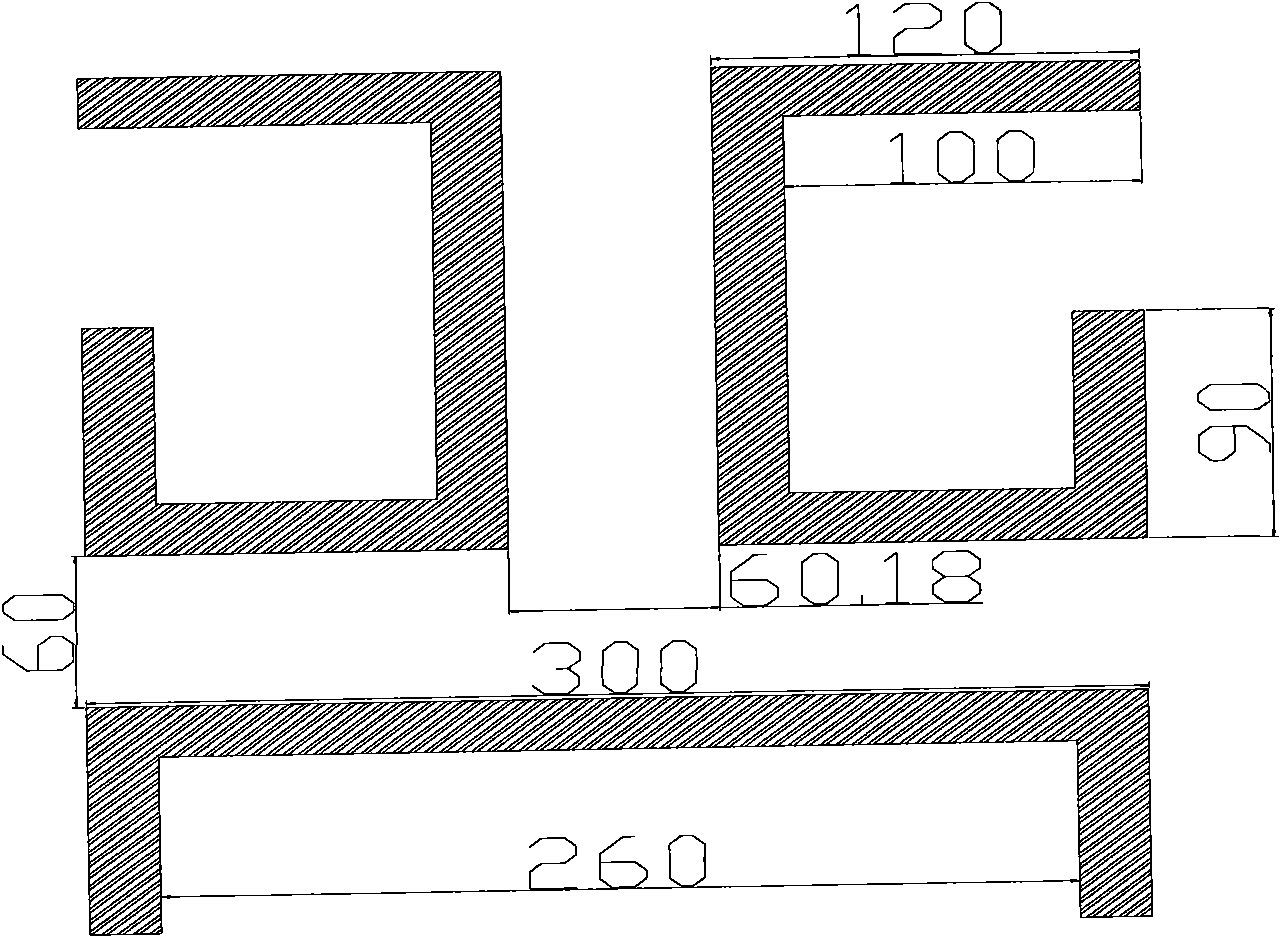

[0027] Below, refer to Figures 1 to 6 , the embodiments of the present invention will be described in detail.

[0028] figure 1 It is an overall structural diagram showing the variable-sonic water jet energy-saving device of the present invention. Such as figure 1 As shown, the variable sound velocity water jet energy-saving device 100 is mainly composed of five parts, including a first shell 1 , a second shell 2 , a third shell 3 , a first inner tank nozzle part 4 and a second inner tank nozzle part 5 .

[0029] The flanges between the first shell 1 and the second shell 2, and the second shell 2 and the third shell 3 are connected by bolts.

[0030] One side outer edge of the first liner nozzle part 4 is clamped between the first shell 1 and the second shell 2 and fixed, and the outer edge of the second liner nozzle part 5 is clamped between the second shell 2 and the third shell 3 fixed between.

[0031] The inner diameters of the first shell 1 , the second shell 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com