A kind of acid mixing method and its acid mixing device

A technology of mixing acid and acid liquid, applied in mixing methods, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of difficult operation, slow start, single structure, etc., to reduce the degree of violence and prevent the occurrence of Dangerous, severity-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

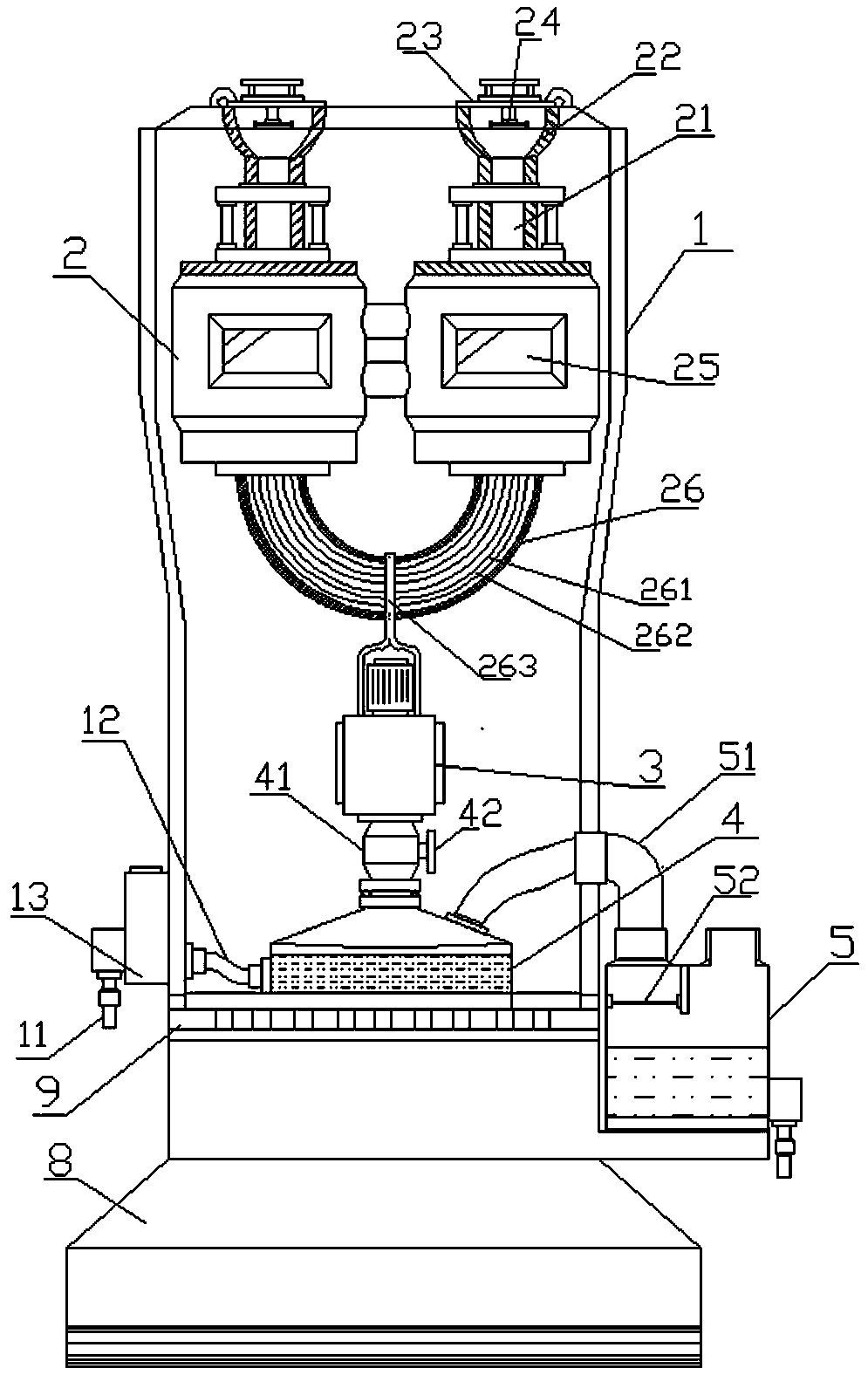

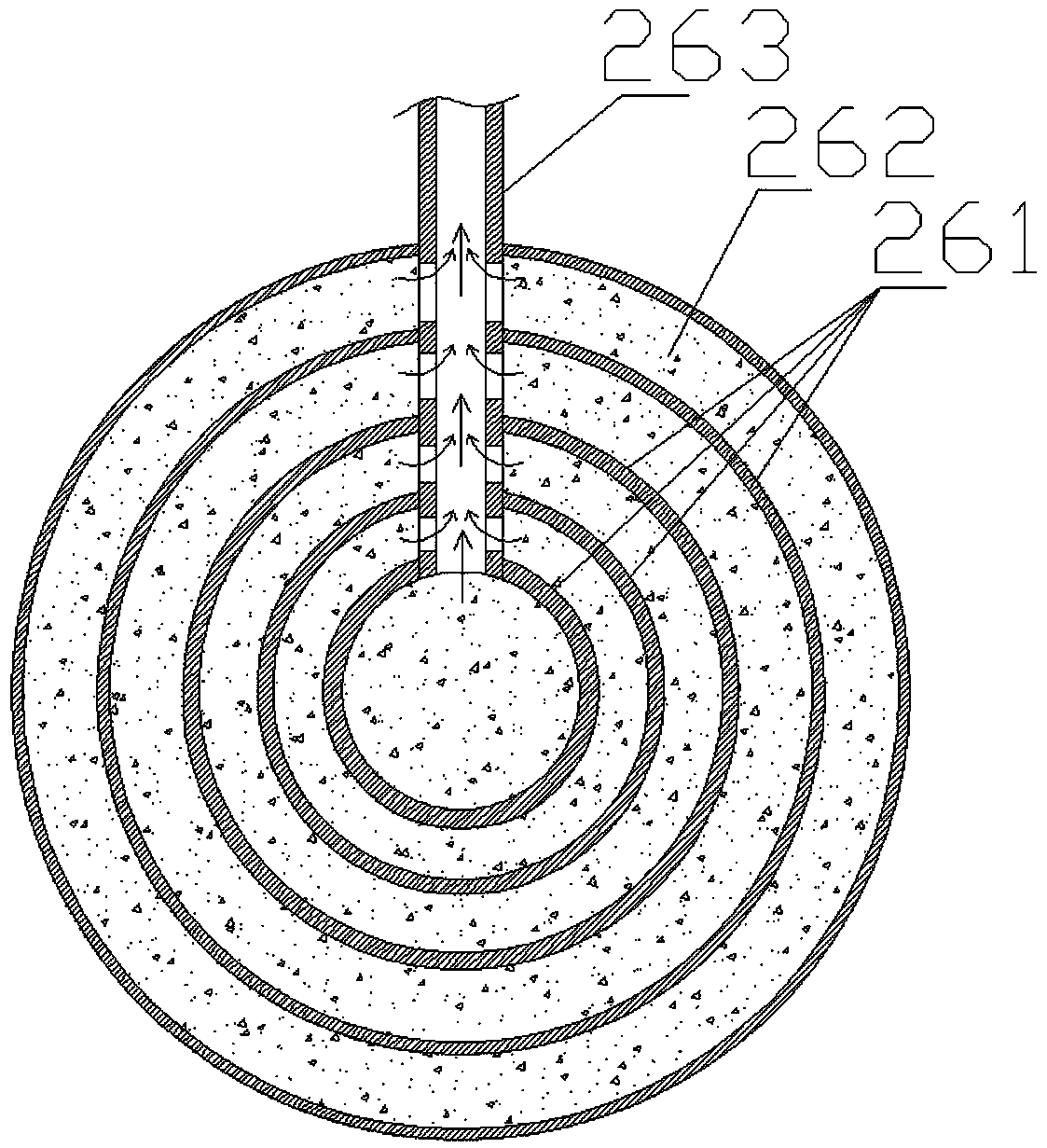

[0036] Embodiment one: see figure 1 , 2, 7, 8, a kind of acid mixing device, a plurality of acid tanks 2 for respectively storing different acid liquids are arranged above the mixed acid mixing room 3; The liquid inlet pipe 26; the upper end of the combined liquid inlet pipe 26 is connected to the acid tank 2, and the lower end is connected to the mixed acid mixing chamber 3 through a pipeline after the lower end is connected to each other; 261 intervals are arranged to form separated first flow passages 262; the first flow passages 262 corresponding to different confluence liquid inlet pipes 26 communicate with each other at the lower end of the confluence liquid inlet pipes 26, so that different acid liquids meet in a separated state; The guide tube 263 passes through the intersection of the inner tubes 261 corresponding to each other, and communicates with the first flow channel 262 respectively, so that the pre-mixed acid liquid flows into the mixed acid mixing chamber th...

Embodiment 2

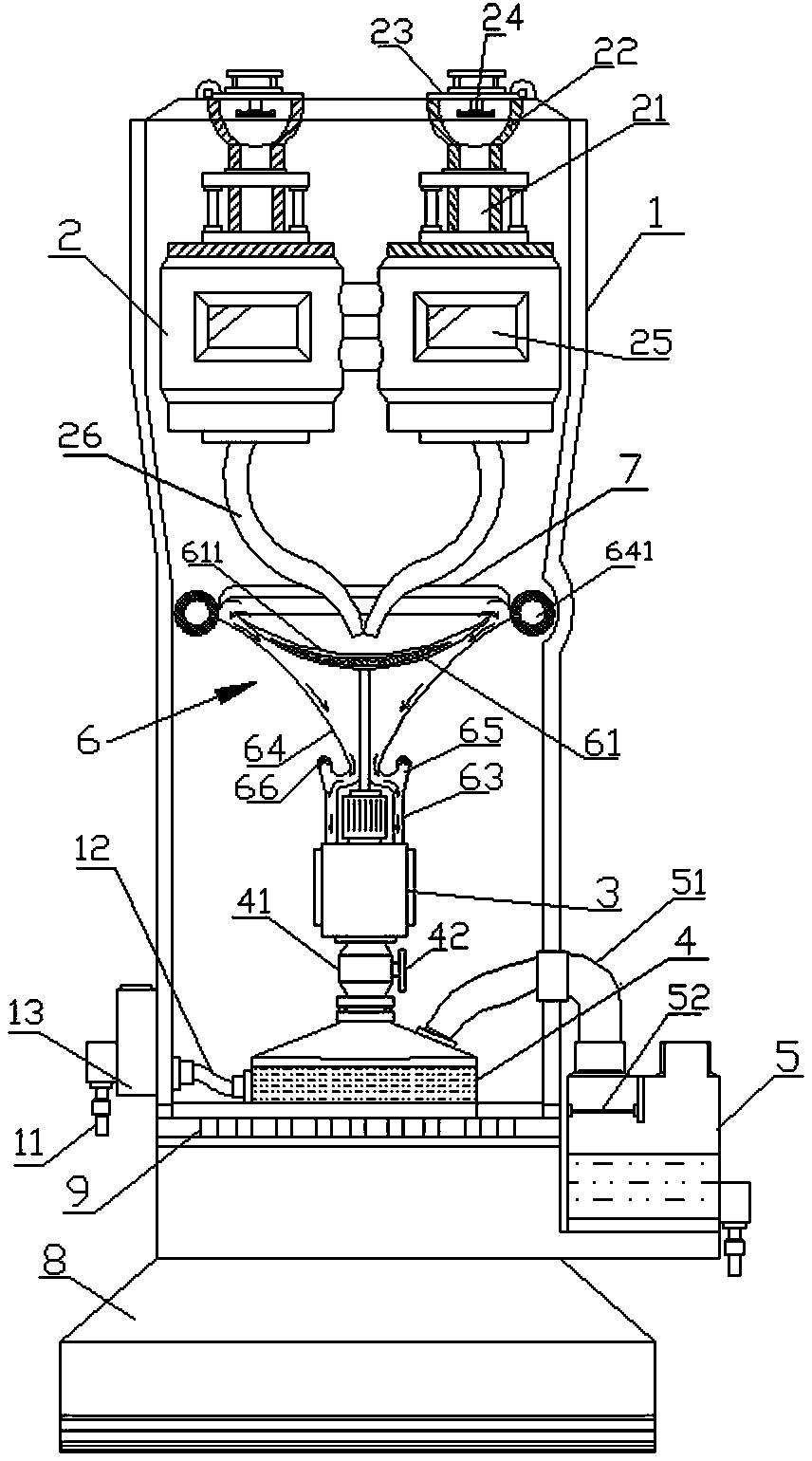

[0037] Embodiment two: see Figures 3 to 8 , an acid mixing device, a plurality of acid cabins 2 for storing different acid solutions are arranged above the acid mixing room 3; a homogenizing device 6 is also arranged between the acid mixing room 3 and the acid cabin 2; The homogenizing device 6 includes a rotating body 61 rotating horizontally; the upper end surface of the rotating body 61 is a bowl-shaped distributing surface 611; the distributing surface 611 is radially distributed with a plurality of mutually separated second The flow channel 612, the second flow channel 612 is respectively defined by the heat conduction sheet 613 fixed on the distribution surface 611; the acid tank 2 guides the acid liquid to the rotating distribution surface 611 through a combined liquid inlet pipe 26 respectively In the middle part, the acid liquid is pre-mixed in the middle part of the distribution surface 611, and then flows out from the outer ring of the distribution surface 611 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com