Polystyrene nanocomposites for blow molding applications

A nano-composite, polystyrene-based technology, applied in the fields of injection stretch blow molding and injection blow molding of styrene-based polymers, can solve problems such as product deterioration and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] To evaluate the effect of clay-based nanocomposites, PS nanocomposites prepared by commercially available polystyrene PS535 from Total Petrochemicals were mixed with 5% by weight of CLOISITE 10A, which was purchased from Southern Clay Products. , the nanocomposite is referred to herein as 535 / 10A. The 535 / 10A blend was compounded with a twin screw extruder and molded into preforms on a Netstal injection molding machine. The preforms were conditioned at room temperature for at least 24 hours before they were stretch blow molded into bottles on an ADSG62 linear injection stretch blow molding machine.

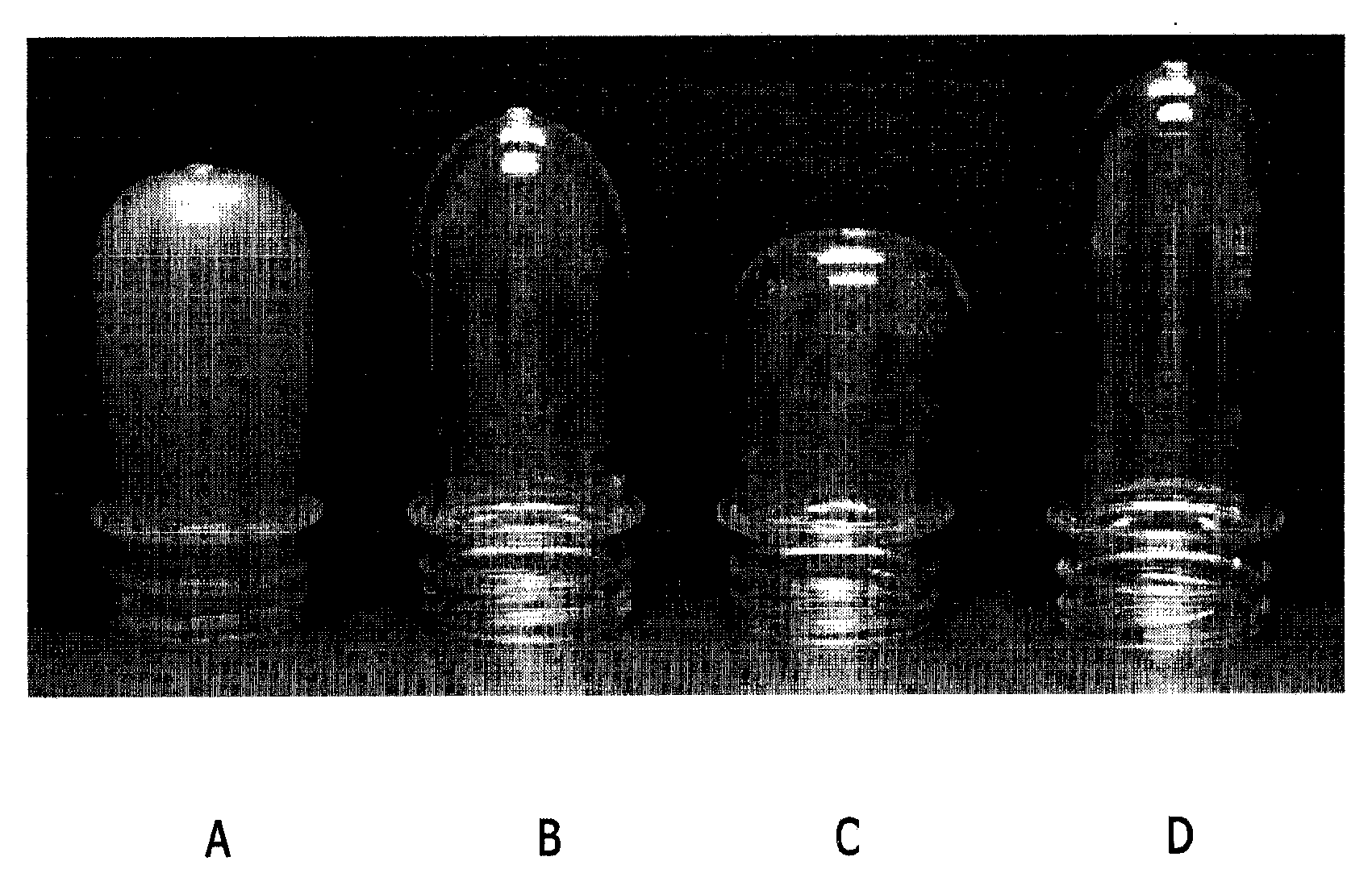

[0076] In the ISBM process, 535 / 10A preforms exhibited lower shrinkage and limited warpage compared to pure PS535 preforms. Thus, the preform was successfully blow molded into bottles under the four conditions shown in Table 3 below.

[0077] Table 3 Summary of processing conditions for PS535 and 535 / 10A preforms

[0078]

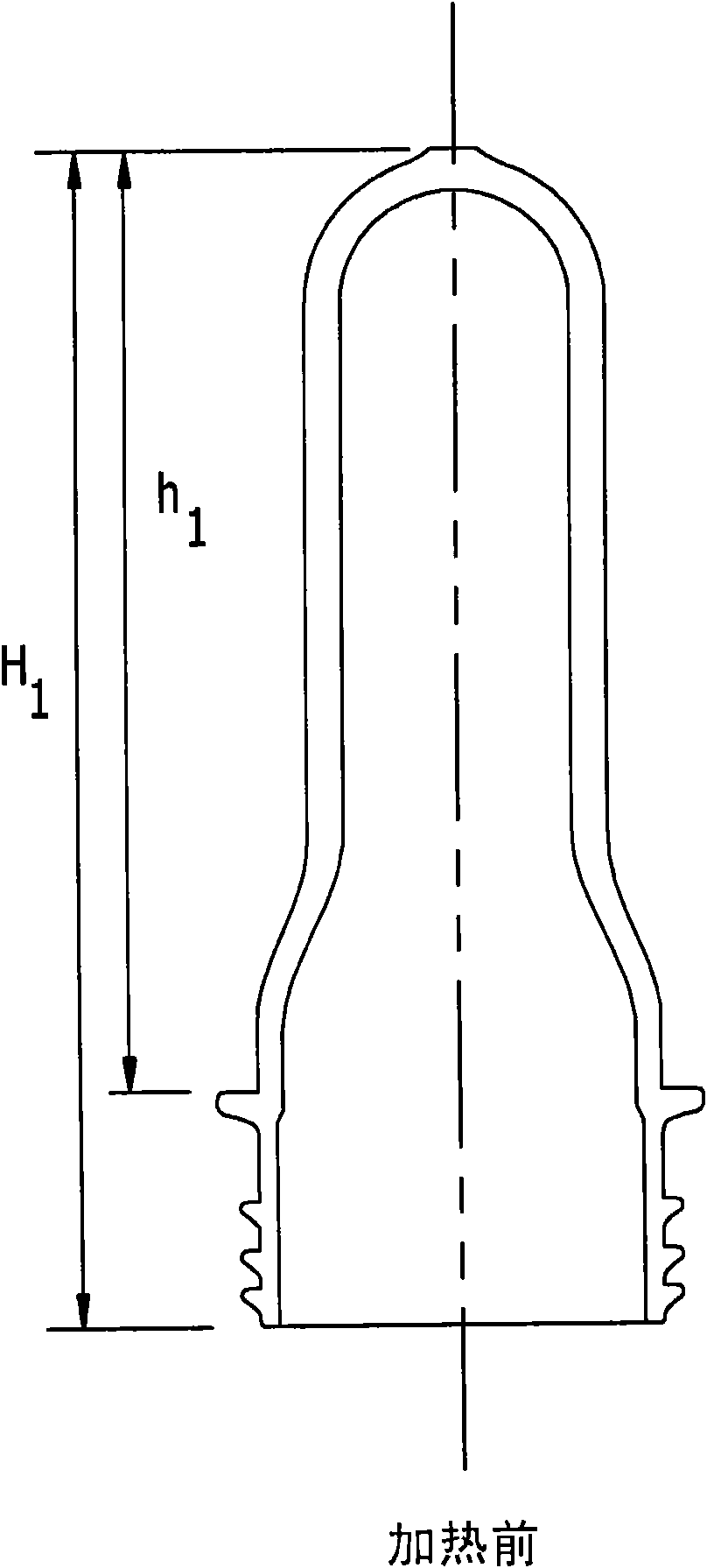

[0079] Figure 3 shows the preform before hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com