Device for connecting two components

A component and receiving groove technology, which is applied in the direction of connecting components, thin-plate connections, threaded fasteners, etc., can solve the problems that the fastening holes of nut sockets and feet cannot be aligned, and increase the difficulty of screwing in fastening screws, etc., to achieve Ease of repeated disassembly and installation, wide applicability, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

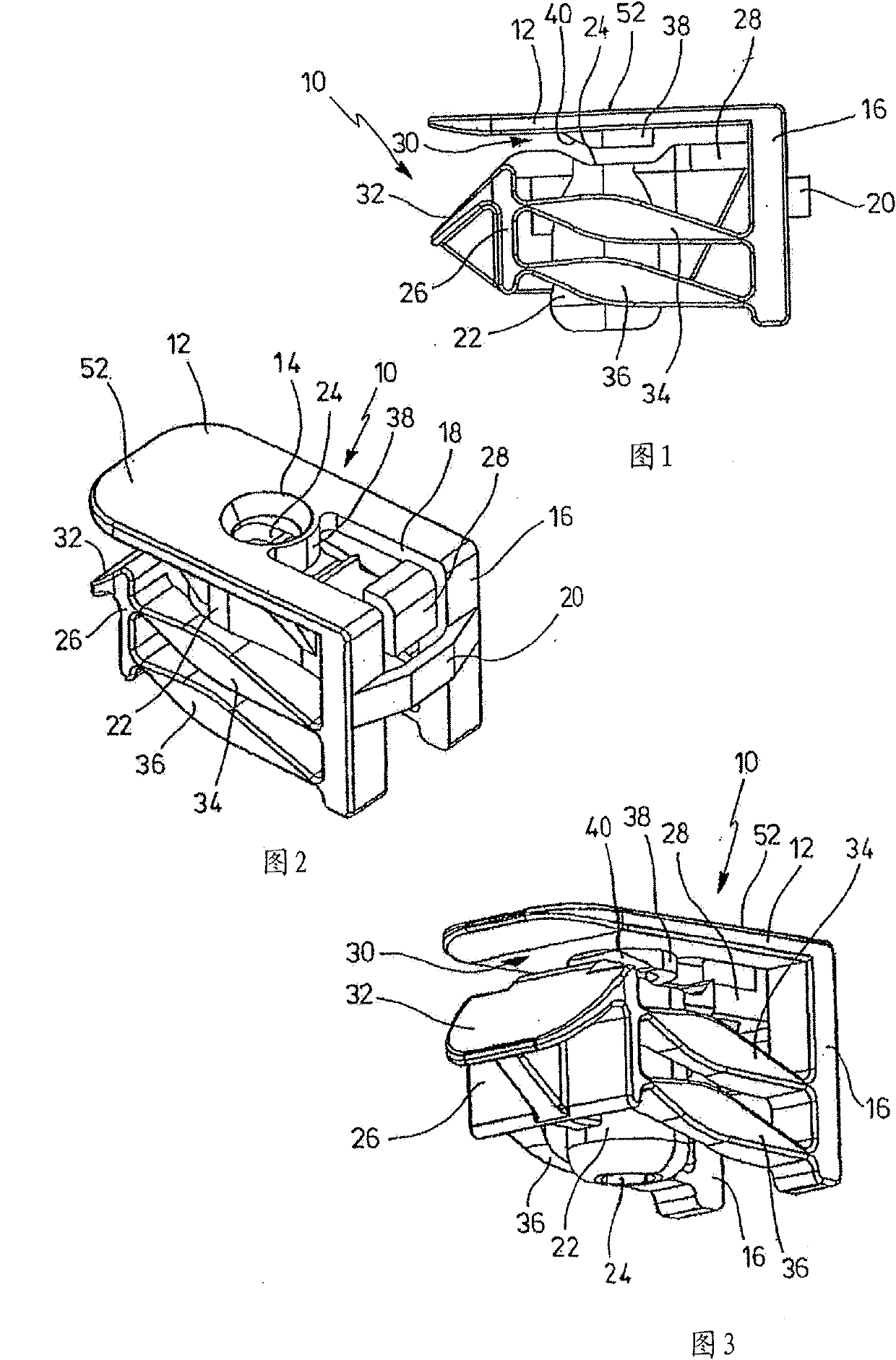

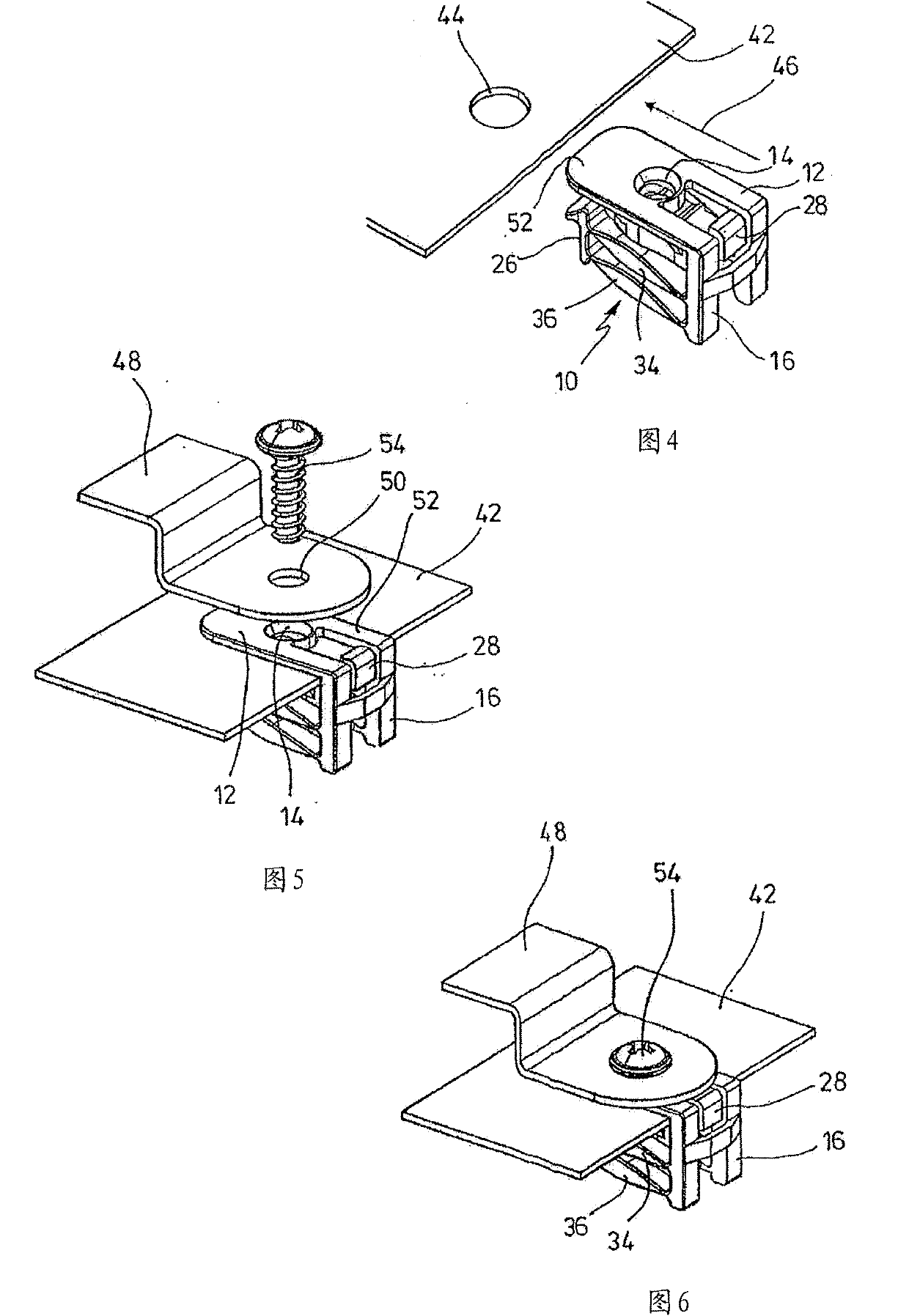

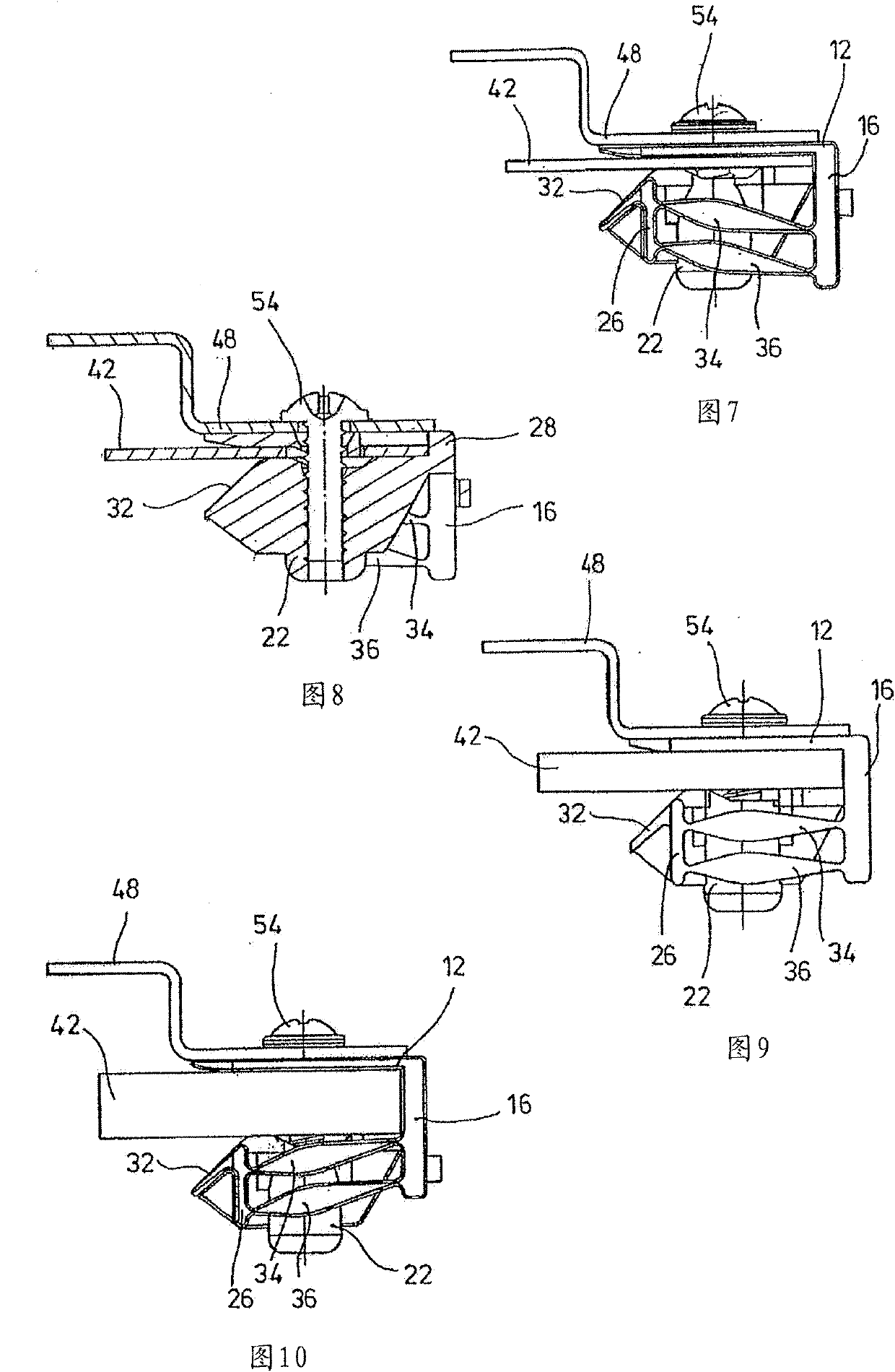

[0028] The drawings use the same names for the same objects unless stated otherwise. Figure 1-3 are different illustrations of the device 10 for connecting two components according to the invention. The device comprises a substantially plate-shaped foot 12 having a circular central fastening hole 14 . One end of the leg 12 is connected to a bracket 16, which in this case consists of two parts. The legs 12 and bracket 16 are substantially at right angles to each other, forming an L-shaped main body. An elongated central groove 18 extends from the foot 12 and extends through the bracket 16 such that the bracket 16 has two parallel sections connected by a connecting rod 20 . And, device 10 also has screw socket 22, in Figure 1-3In the exemplary embodiment shown, the screw socket 22 is substantially cylindrical. The screw socket 22 has an internally threaded hole 24 aligned with the fastening hole 14 of the leg 12 . In the example, the internal thread of the threaded hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com