Chromatic car spraying method

A color registering and automotive technology, applied to coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as stencil engraving errors, inaccurate positioning, and pattern errors, so as to improve uniformity, save man-hours, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0022] In the present invention, in the case of no contrary description, the orientation words used such as "upper" and "lower" usually refer to the top and bottom of the vehicle body, and the "length" of the template refers to the size of the template along the length direction of the vehicle body. The "width" of the template refers to the dimension of the template along the height direction of the vehicle body.

[0023] The present invention provides a kind of automobile color registration spraying method, and this method comprises the following steps:

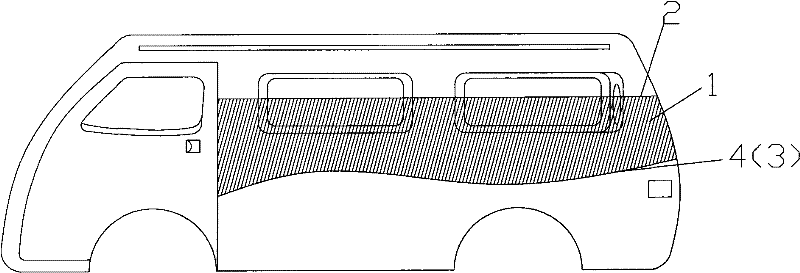

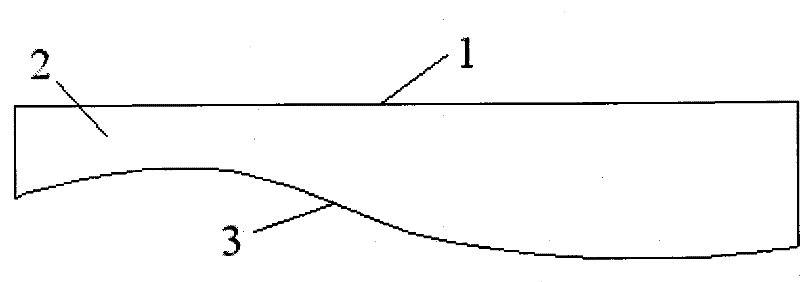

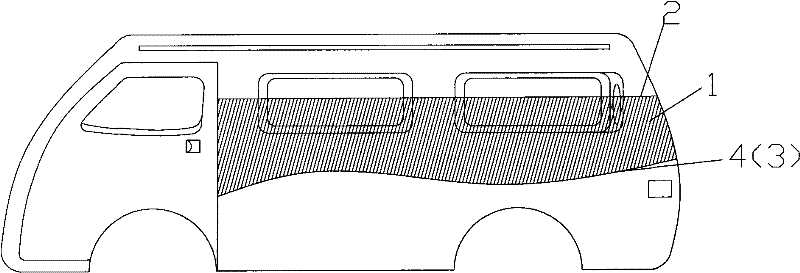

[0024] (a) making template 1, at least a part of edge 3 of this template 1 is consistent with at least a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com