Chemical mechanical grinding device

A grinding device, chemical machinery technology, applied in the direction of grinding devices, grinding machine tools, working carriers, etc., can solve the problems of machine energy loss, noise, mechanical parts wear, etc., to achieve the effect of reducing losses, reducing noise, and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

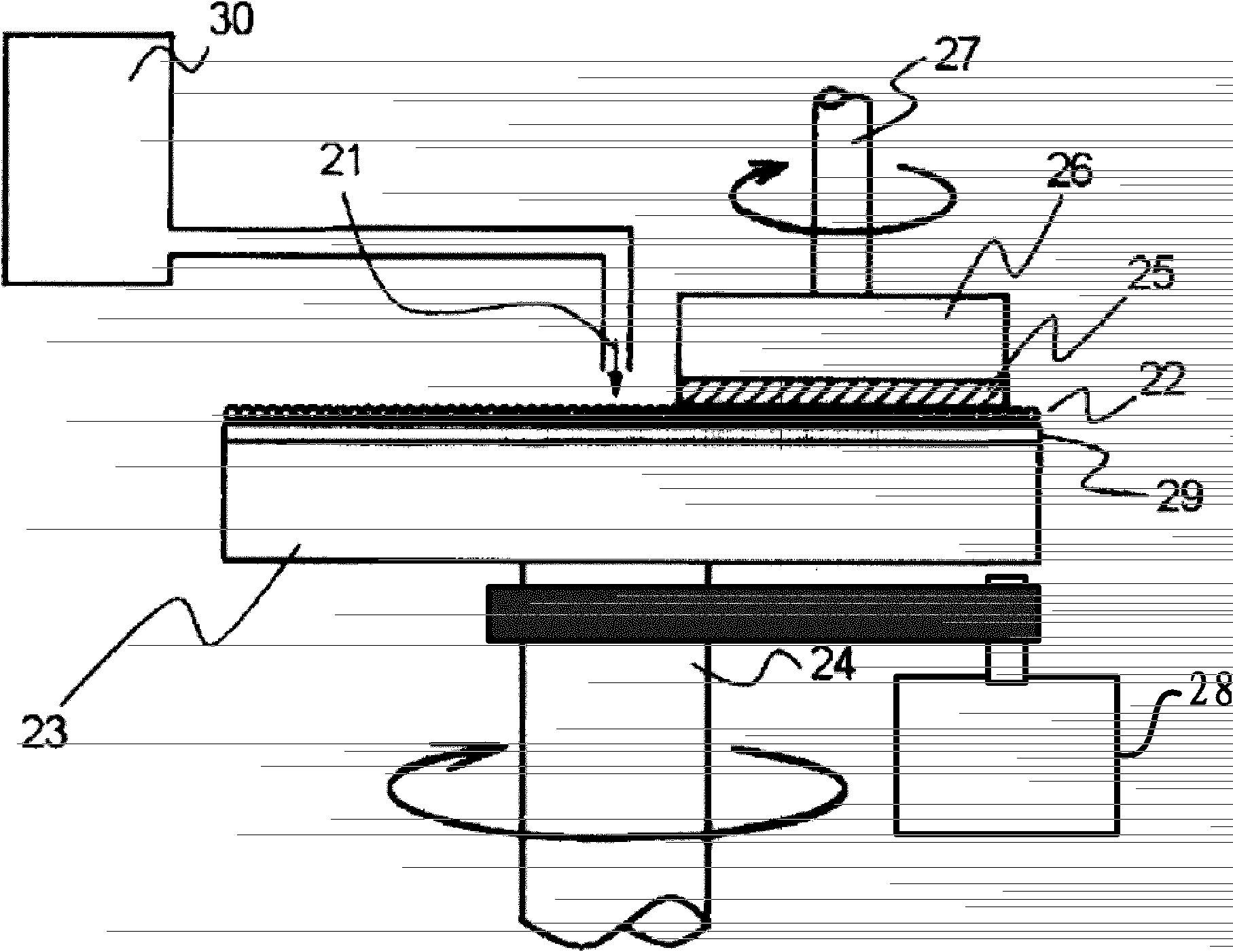

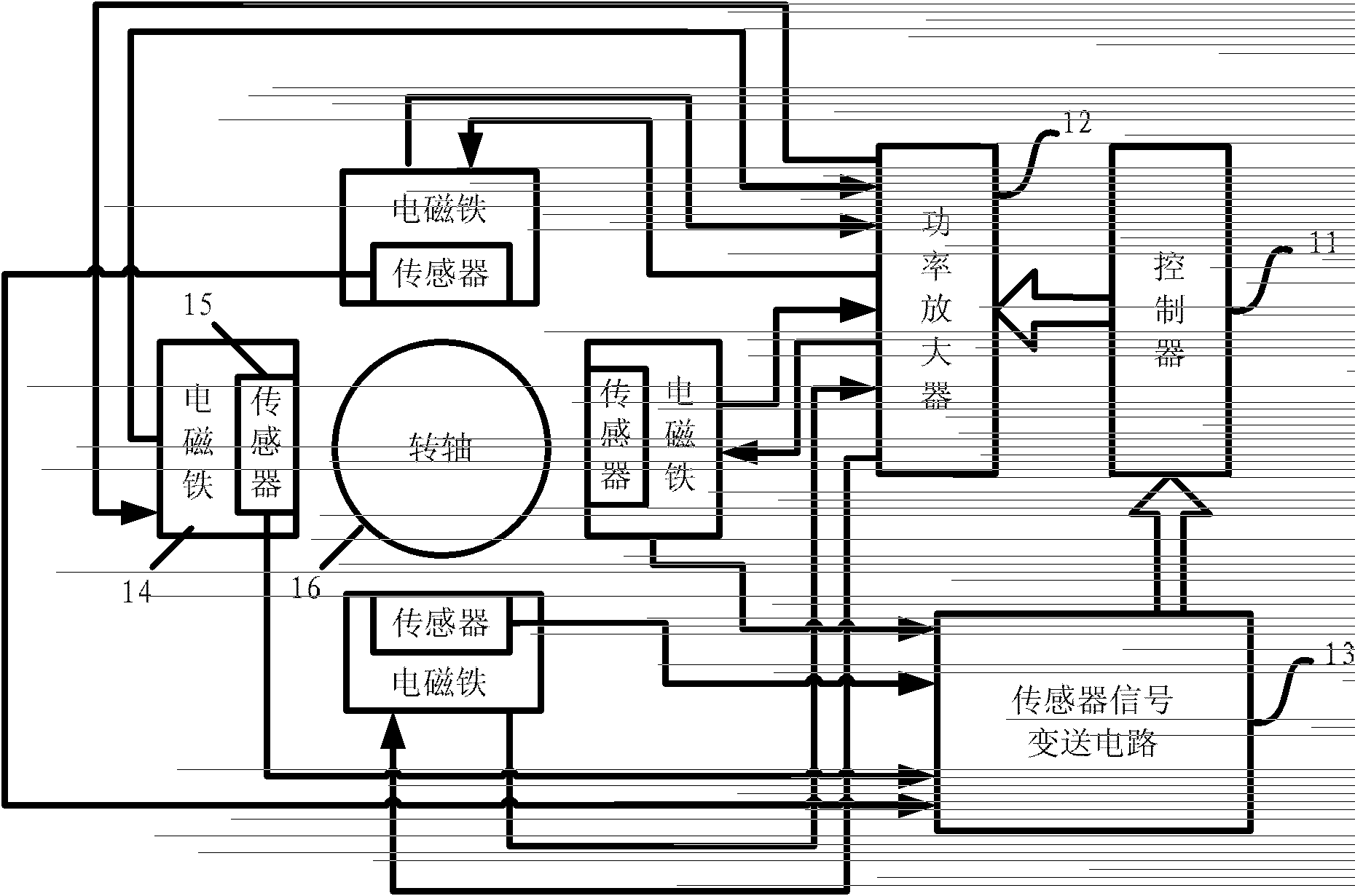

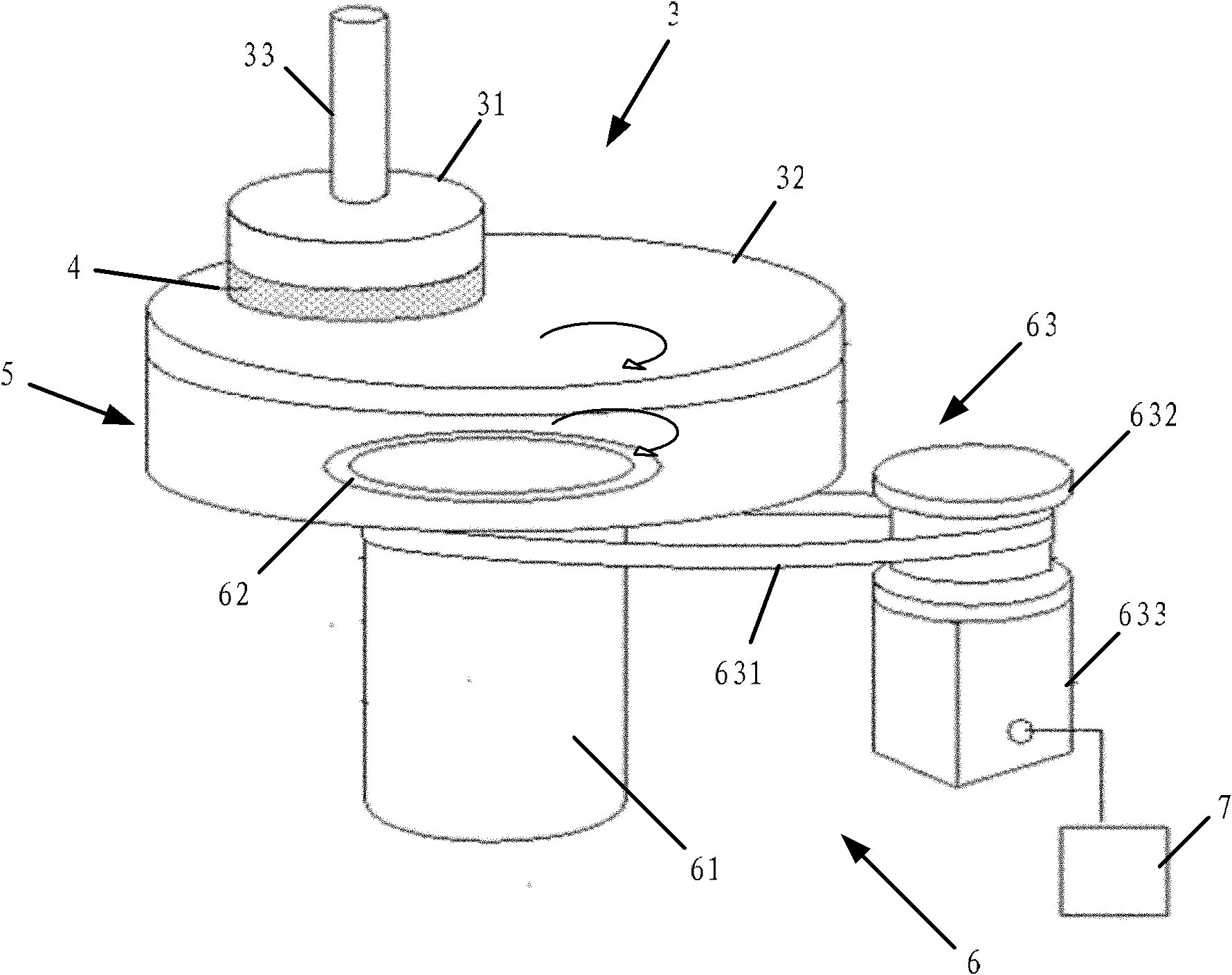

[0025] The inventor has carried out sufficient research on the bearing structure in the field of semiconductor industry, and has accumulated a large amount of practical experience in production, aiming at the existing problems, proposes a technical scheme of a polishing pad of a chemical mechanical polishing device described in the present invention, which is different from the existing The difference in technology is that the present invention utilizes the magnetic suspension bearing as the grinding pad bearing, and its main principle is to suspend the grinding pad above the magnetic suspension bearing by generating a magnetic suspension force on the magnetic suspension bearing, so that there is no gap between the magnetic suspension bearing and the magnetic suspension bearing. The mechanical contact, in turn, enables the polishing pad to run more smoothly, thereby reducing mechanical wear, energy loss, and reducing noise.

[0026] In order to make the above objects, features ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com