Bending actuator element and bending actuator module

A technology of bending converters and components, applied in electrical components, piezoelectric/electrostrictive/magnetostrictive devices, textiles and papermaking, etc., can solve the problems of high damage rate, high fracture sensitivity, etc., and achieve a reduction in damage rate , protection from damage, protection from external influences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

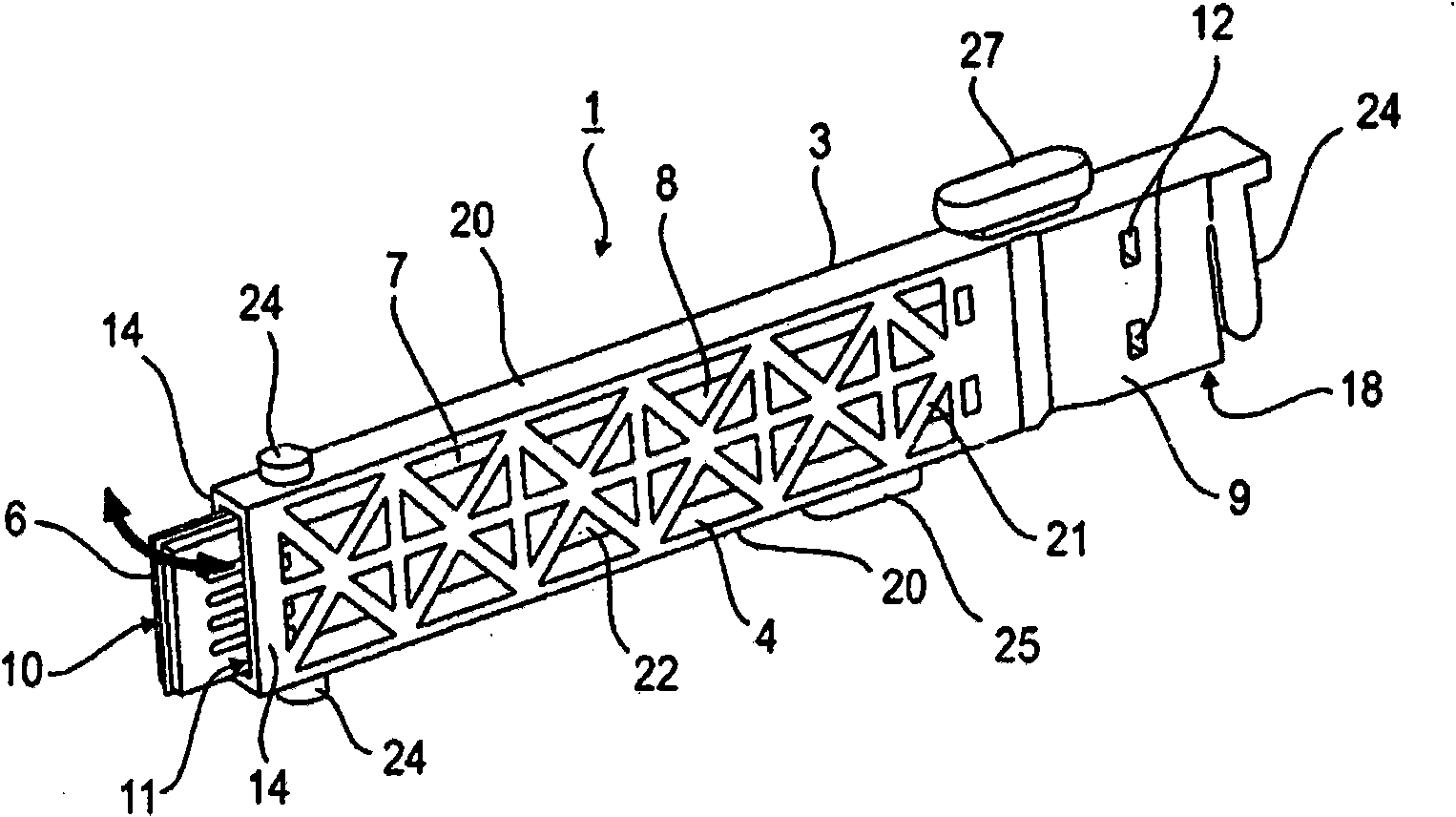

[0042] figure 1 The bending converter element 1 is shown in a perspective view, comprising a protective housing 3 and a bending converter 4 arranged in the protective housing 3 . The bending converter 4 arranged in the housing 3 has a flat carrier 6 which is provided on both sides with a piezoelectrically active covering layer 7 . The bending converter 4 is fastened with its fastening end 9 inside the protective housing 3 . At the opening 11 of the protective housing 3 a floating end 10 of the bending converter 3 protrudes, which is movable in the direction indicated by the arrow.

[0043] The protective housing 3 is formed as a one-piece injection-molded part of glass-fibre-reinforced ABS plastic. For assembly, the bending adapter 4 is introduced into the interior of the protective housing 3 starting from the opening 11 with the fastening end 9 at the front. A clamping receptacle for bending the free end 10 of the converter 4 is integrally formed at the end of the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com