Drilling fluid

A technology of drilling fluid and fluid loss control agent, which is applied in the field of drilling fluid and can solve problems such as difficult hydraulic calculations, explosions, and rapid attenuation of pulse signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

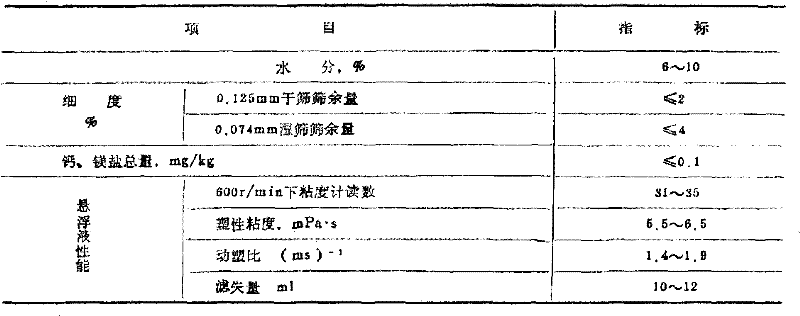

Method used

Image

Examples

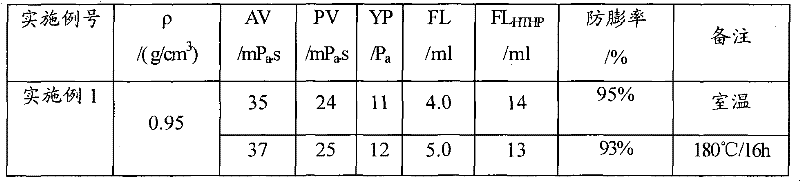

Embodiment 1

[0139] Add 2 parts of bentonite into water, stir for 30 minutes, and age for 24 hours; under stirring, add 0.2 parts of high temperature resistant fluid loss reducer DSP-2, 1.0 part of high temperature resistant viscosity increase fluid loss reducer LY-1 and 0.5 parts Add 1 part of amino polyalcohol shale inhibitor AP-1 to the prepared bentonite slurry in turn, stir for 10 minutes, then add 10 parts of hollow glass microspheres HGS8000, and continue stirring for 20 minutes to obtain high temperature resistant low density drilling fluid.

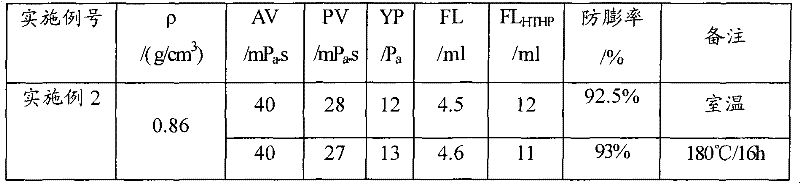

Embodiment 2

[0141] Add 2 parts of bentonite to water, stir for 30 minutes, and age for 24 hours; under stirring, add 0.5 parts of high temperature resistant fluid loss reducer DSP-2, 0.5 parts of high temperature resistant viscosity increase fluid loss reducer LY-1 and 0.5 parts Add one part of amino polyalcohol shale inhibitor AP-1 to the prepared bentonite slurry in turn, stir for 10 minutes, then add 20 parts of hollow glass microspheres HGS8000, and continue stirring for 20 minutes to obtain high temperature resistant low density drilling fluid.

Embodiment 3

[0143] Add 1 part of bentonite to water, stir for 30 minutes, and age for 24 hours; under stirring, add 0.5 part of high temperature resistant fluid loss reducer DSP-2, 0.8 part of high temperature resistant viscosity increase fluid loss reducer LY-1 and 1.0 Add 1 part of amino polyalcohol shale inhibitor AP-1 to the prepared bentonite slurry in turn, stir for 10 minutes, then add 30 parts of hollow glass microspheres HGS8000, and continue stirring for 20 minutes to obtain high temperature resistant low density drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com