A Construction Method for Preventing Filling Wall Cracks

A construction method and a technology of filling walls, which are applied in the processing of building materials, building components, building insulation materials, etc., can solve problems such as maintenance difficulties, affecting the normal use of residents, and high wind pressure on the outer wall, and achieve simple operation and engineering The effect of safe and reliable quality and reasonable design of construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

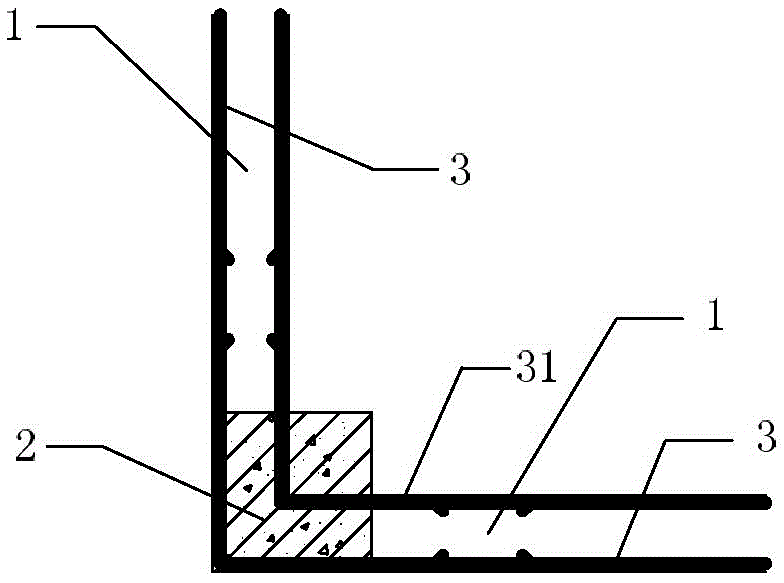

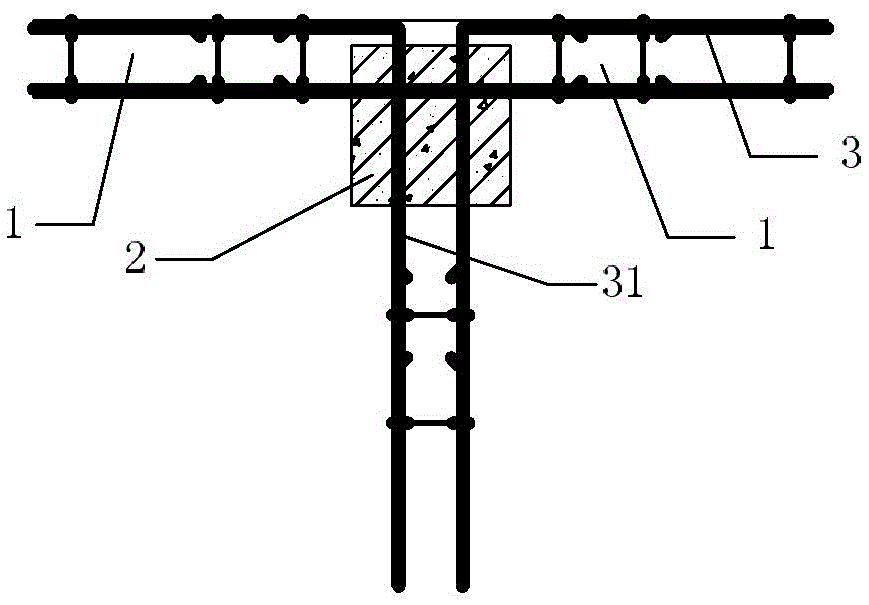

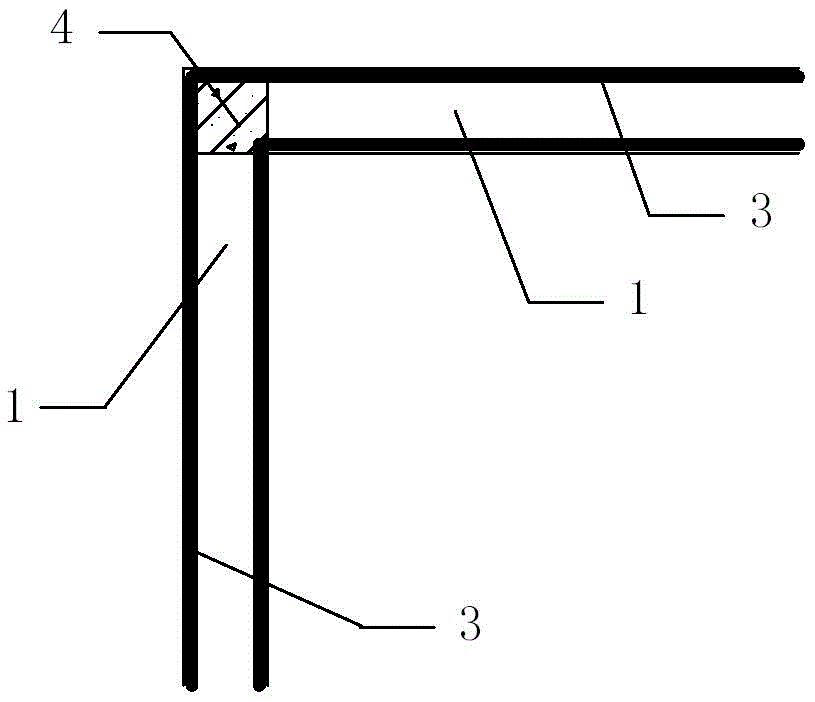

[0030] A construction method for preventing cracks in a filling wall. The filling wall includes an inner wall and an outer wall, and is characterized by including the following steps:

[0031] a. Infill wall masonry, the inner wall is built with 190mm thick lightweight aggregate concrete small hollow blocks, and the outer wall is built with sintered coal gangue porous bricks. The size and thickness of the blocks are consistent with the thickness of the shear wall to avoid The thickness of the plastering layer on both sides of the subsequent transfer of different materials is inconsistent; use medium-coarse Mb7.5 cement mortar or Mb7.5 cement mixed mortar for masonry mortar. Mountain sand shall not be used, and the mud content of the sand shall be controlled below 5% ; Mortar consistency is 50~80mm, mortar stratification is 10~30mm; inner wall block density is 1000kg / m 3 Below, the bulk density of external wall blocks is 1250kg / m 3 Below, the bulk density refers to the weight of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com