Method and controller for determining the height of work equipment equipped with a pivoting element

A technology of working height and working equipment, applied in the direction of load hanging components, height/level measurement, instruments, etc., can solve the problems of inaccuracy, pollution of stroke measuring devices, pollution, etc., and achieve the effect of flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

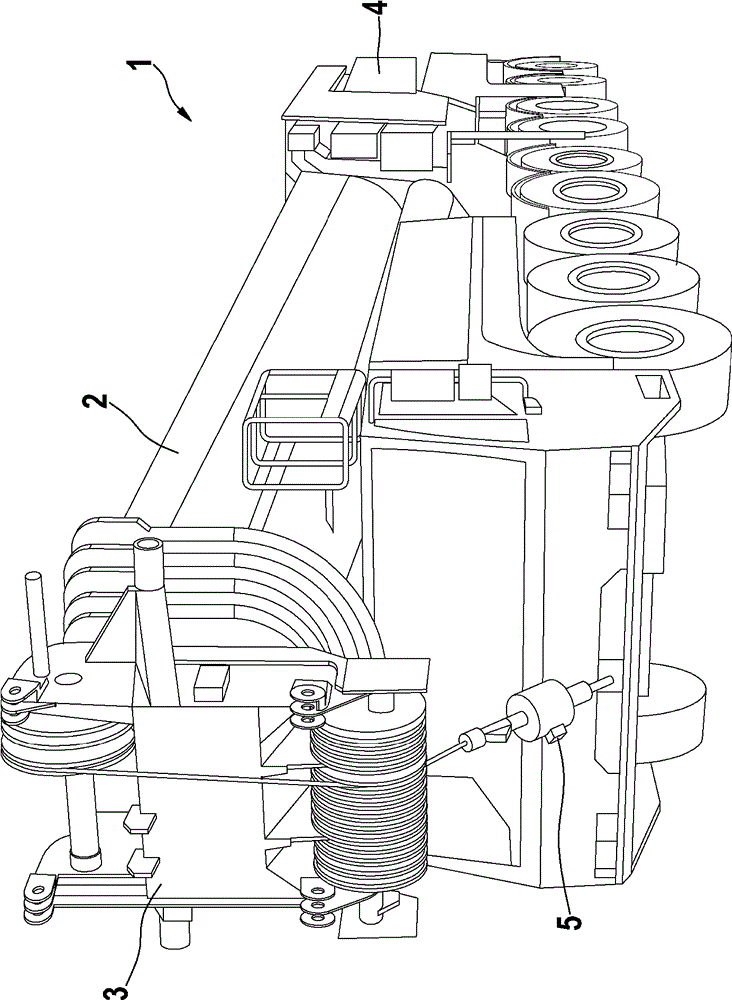

[0027] figure 1 Shown is a working device with a variable working height. This is a crane 1 with an outrigger 2 whose length can be adjusted. The outrigger 2 is movably anchored to the crane 1 with one end thereof, while the front end is placed on the driver's cab of the crane 1 in a freely movable manner. At the end of the jib 2 that is movably connected to the crane 1, a crank device is arranged, by means of which the jib 2 can be raised so that the freely movable end of the jib 2 is released from the driver's cab of the crane 1 . A first control 3 is arranged on the freely movable end of the extension arm 2 . The second controller 4 is located on the base of the boom 2 where the boom 2 is movably connected to the crane 1 . A third control 5 is arranged on a suspension mounted on the freely movable end of the boom 2 .

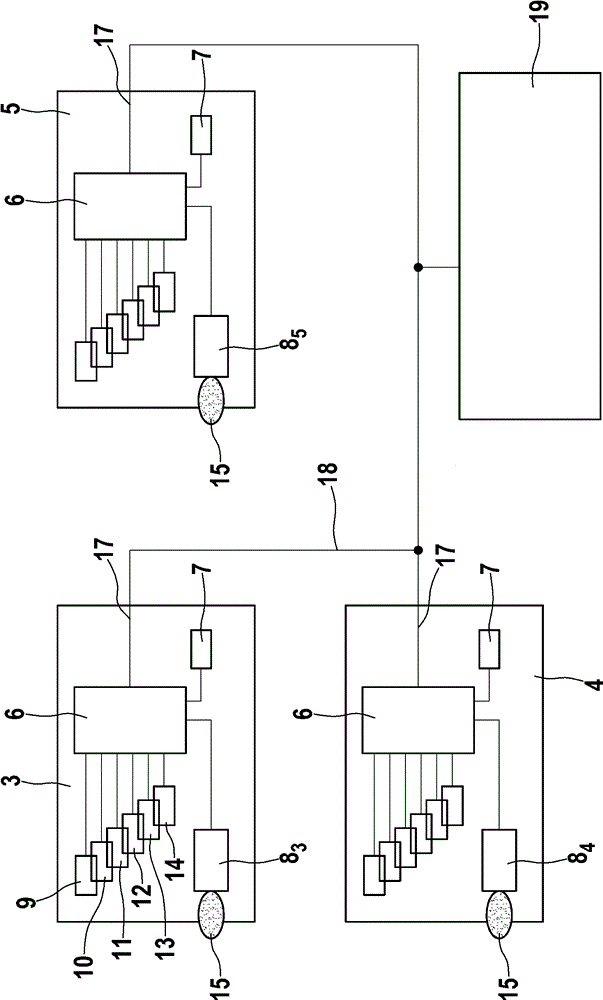

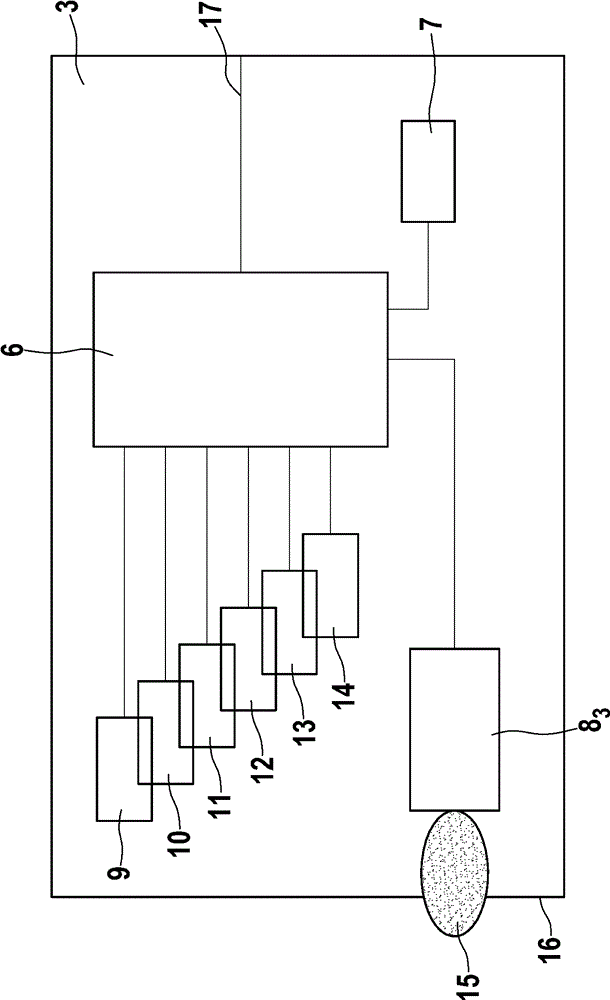

[0028] All three controllers 3, 4, 5 have a consistent structure which should be aided by figure 2 3 instructions for the controller. The controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com