Drum type washing machine

A drum-type washing machine, washing machine technology, applied to other washing machines, washing machine appliances, washing machines with containers, etc., capable of solving problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

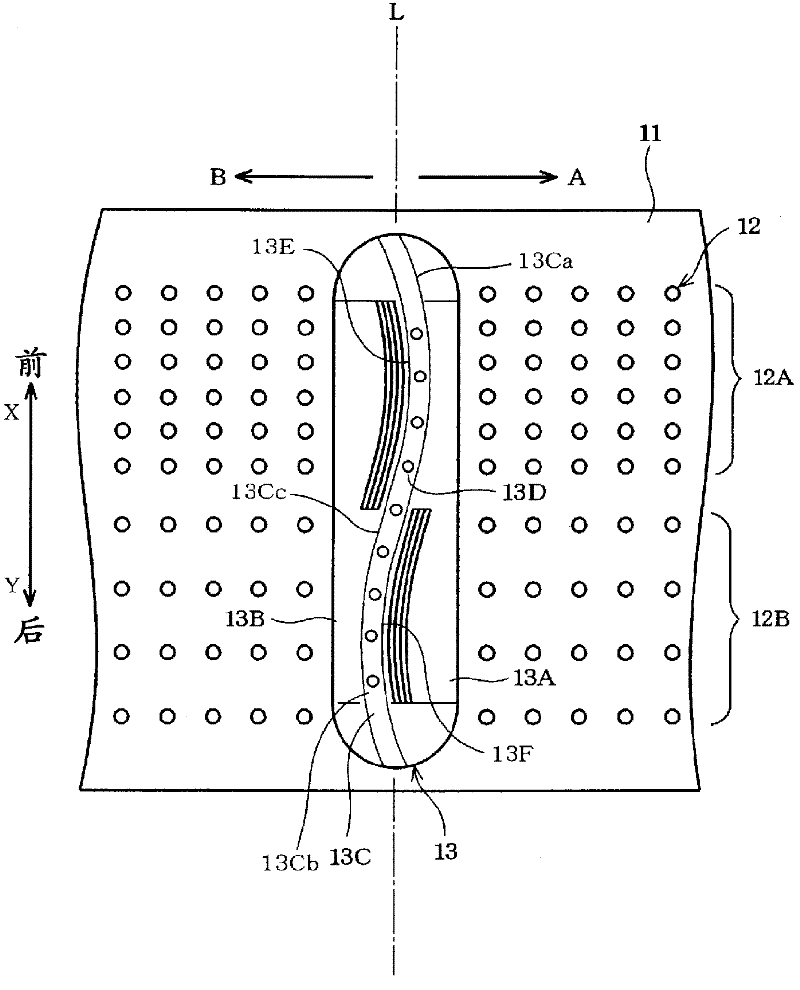

[0054] For the first embodiment, refer to Figure 1 to Figure 19 illustrate.

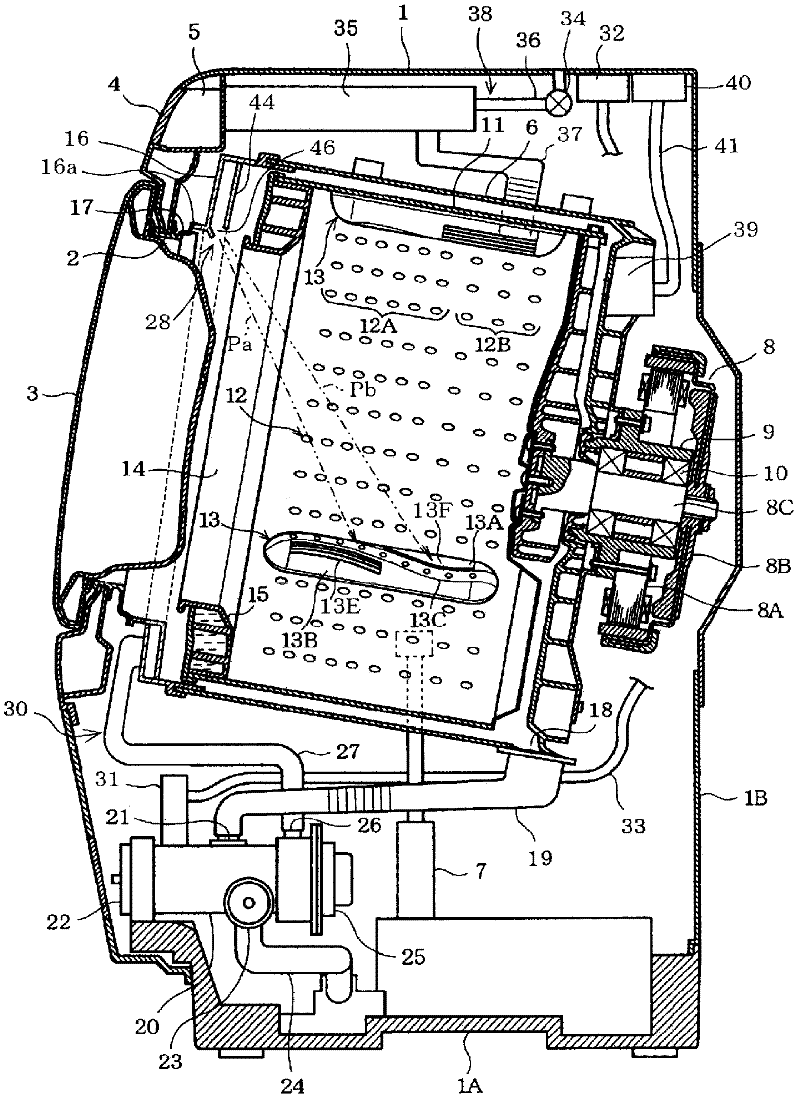

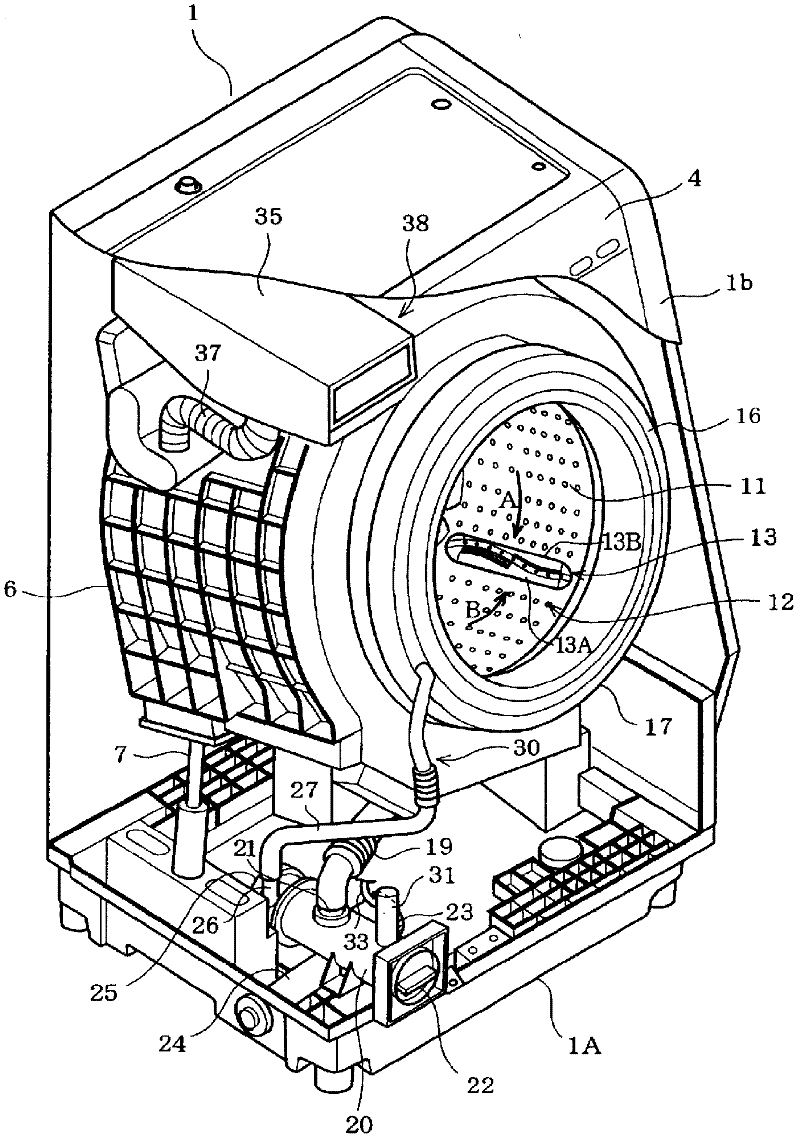

[0055] First, in figure 1 with figure 2 The overall structure of the front-loading washing machine is shown in . The outer case 1 of the front-loading-type washing machine specifically includes a base 1A made of synthetic resin and a case main body 1B coupled to the base 1A. On the front part of the box main body 1B (in figure 1 The roughly central portion of the middle left side) forms the laundry inlet and outlet portion 2 . The door 3 has a double-glazed structure, and opens and closes the laundry inlet and outlet 2 . An operation panel 4 is provided on an upper portion of the front portion of the box main body 1B. On the rear side of the operation panel 4 (inside the outer case 1 ), a control device 5 as a control unit is provided.

[0056] Inside the outer case 1 is provided a bottomed cylindrical water tank 6 with the back side closed. Tank 6 is elastically supported by suspension 7 i...

no. 2 Embodiment approach

[0097] Figure 20 Regarding the second embodiment, for the above-mentioned first embodiment ( Figure 17 ) are assigned the same symbols. This second embodiment deletes the AND current converter 51 (refer to Figure 11 ) related to the judging step S10, processing step S11, judging step S17 and processing step S18. That is, the present embodiment is a configuration in which the current converter 51 is omitted.

no. 3 Embodiment approach

[0099] Figure 21 Relate to the 3rd embodiment, with respect to above-mentioned 1st embodiment (referring to Figure 14 to Figure 16 ) are marked with the same symbols. In this third embodiment, at the initial stage of the washing process, the drum 11 (refer to figure 1 , figure 2 ) of the forward rotation time (in this case, 20 seconds, 30 seconds, 40 seconds) is divided into multiple forward rotation times and stop times to execute. According to this configuration, generation of foam can be suppressed as much as possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com