Screwed pipe joint and method for the production thereof

A technology for threaded pipes and threaded connectors, applied in the field of threaded pipe joints and their manufacturing, can solve the problems of easy rotation of pipes, damage to anti-corrosion coatings of pipes, expensive deformation of machine tools, etc., and achieve the effect of improving assembly characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

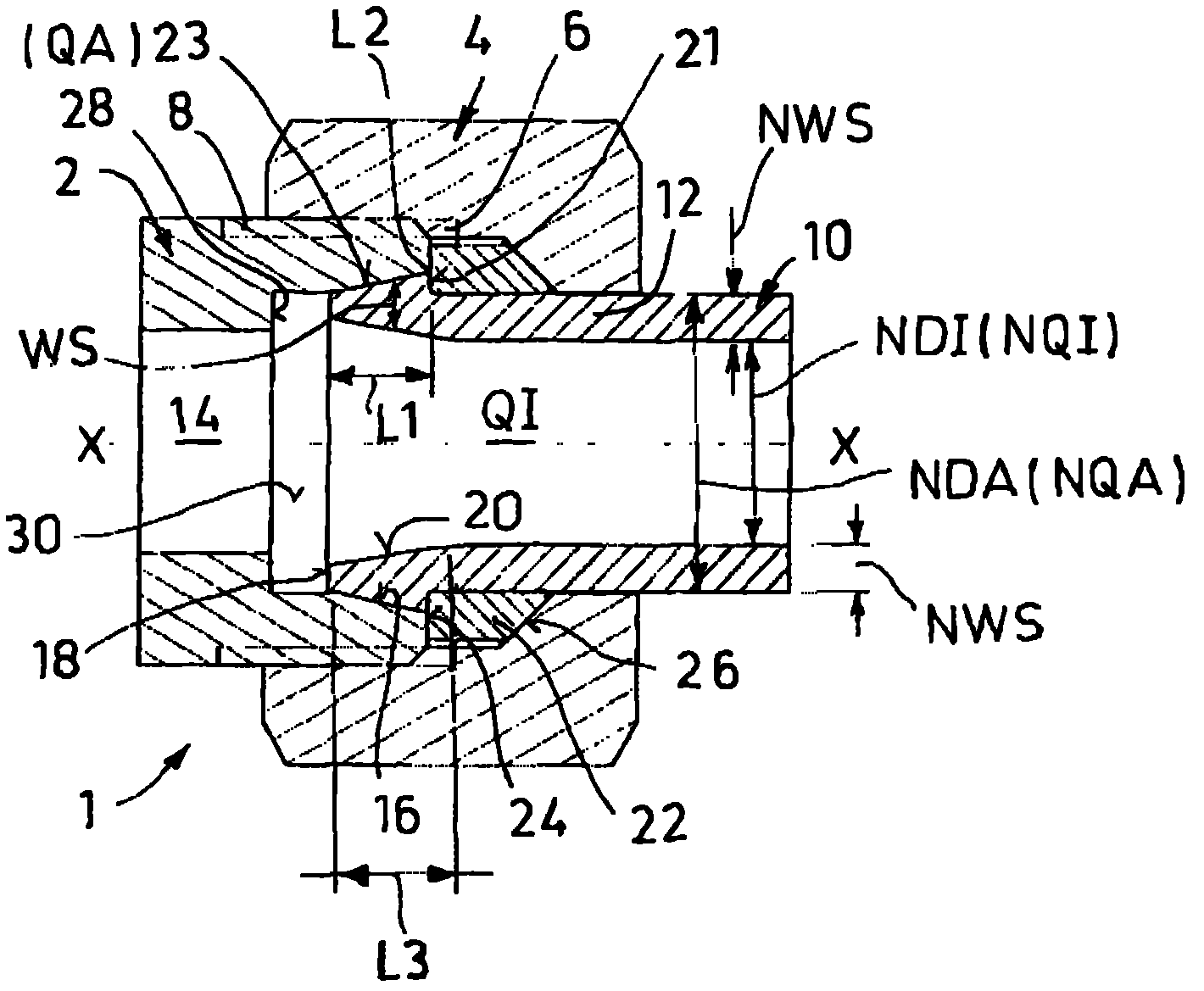

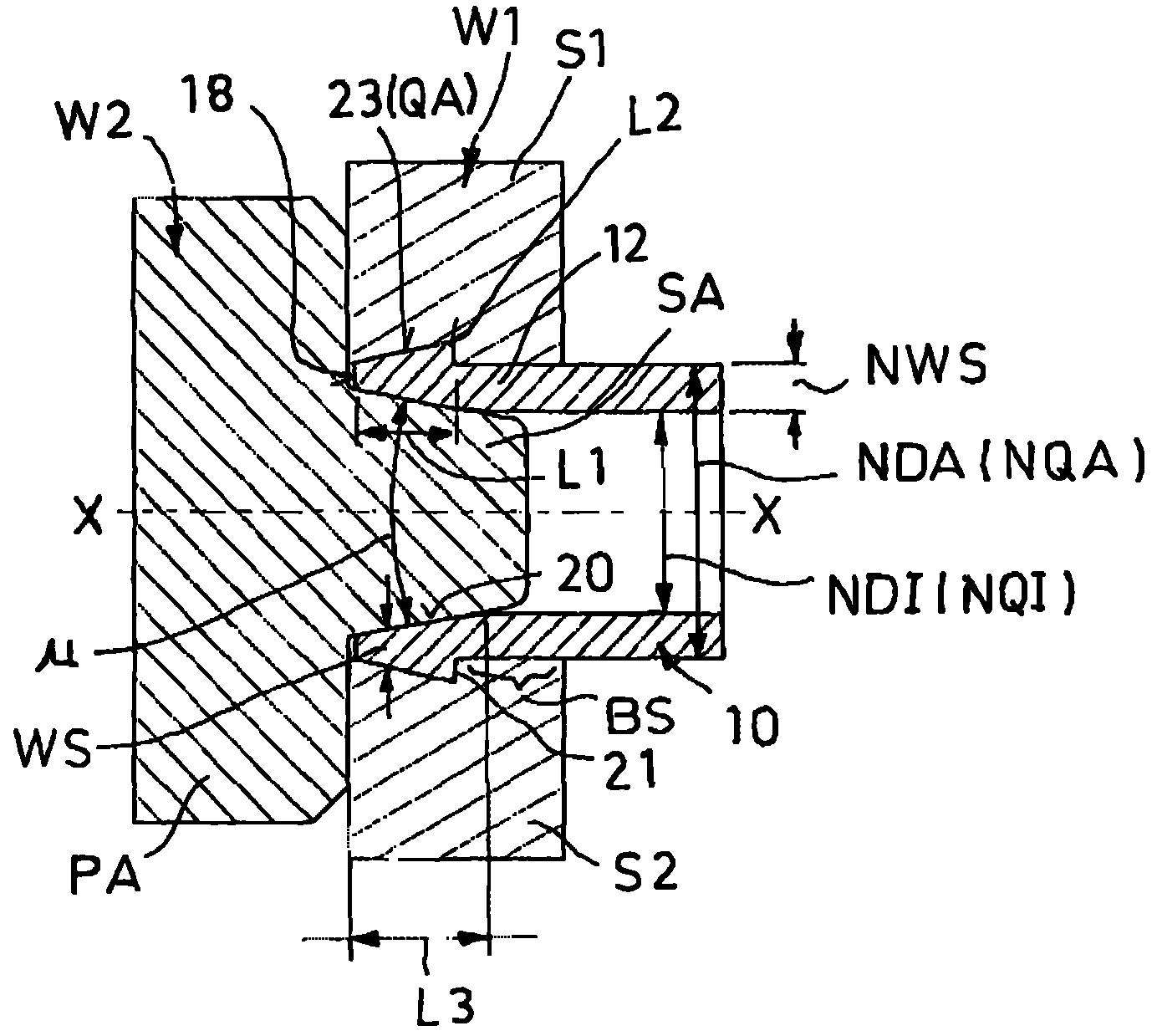

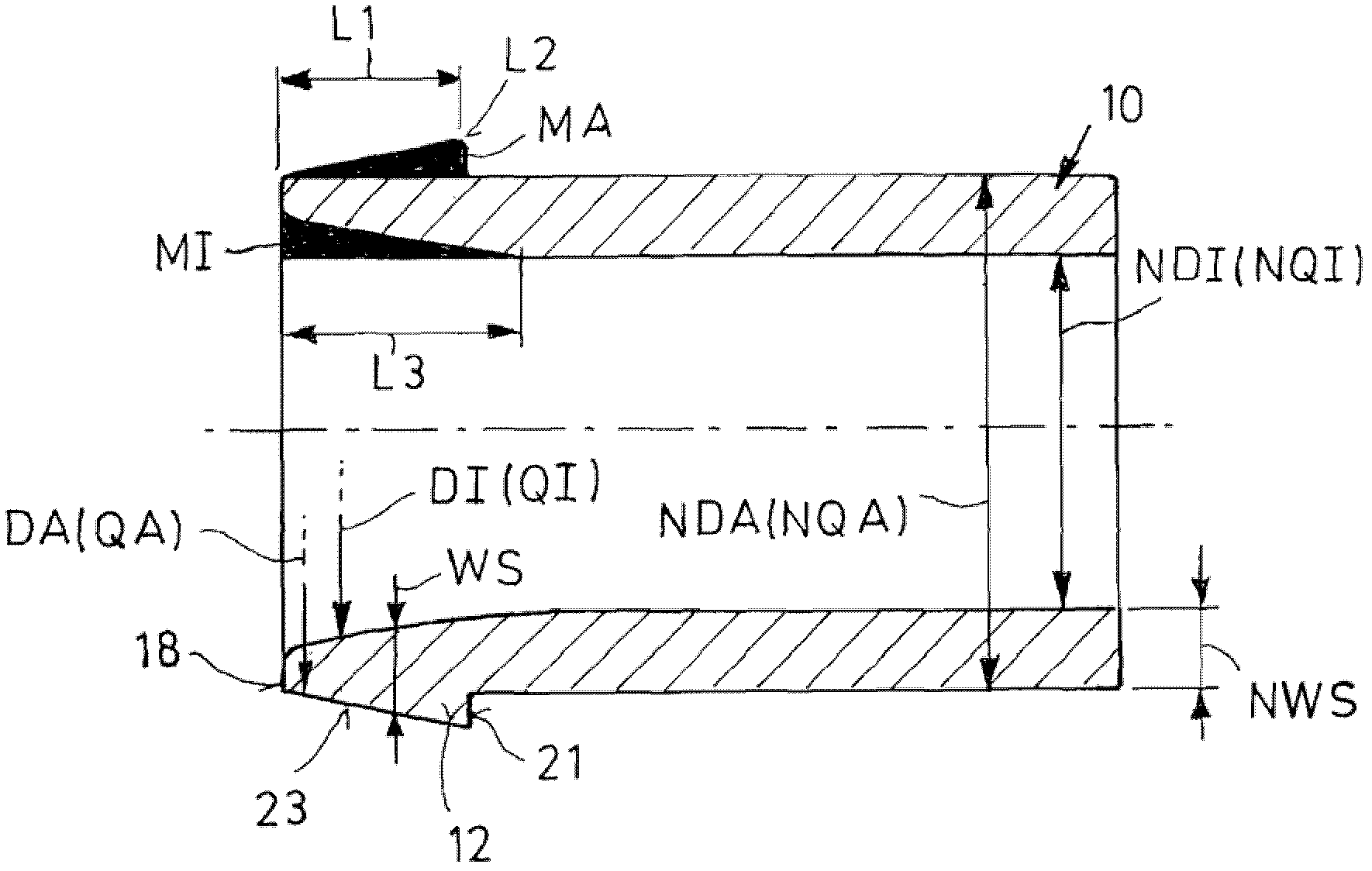

[0049] First, if figure 1 As shown, the threaded pipe joint 1 according to the present invention comprises a plug-in part 2 in the form of a plug-in support and a threaded connection part 4 with a cap seal, which is usually configured as a cap nut, which by means of an inner The thread 6 can be screwed onto the external thread 8 of the plug connector 2 . The pipe 10 to be connected, in particular made of metallic material, has a plug-in end 12 which can project into a receiving opening 14 of the plug-in part 2 . The receiving opening 14 has an inner conical surface 16 which widens outwards in the direction of the pipe 10 . In order to hold the pipe 10 in a tight manner, the pipe wall region of the plug end 12 of the pipe 10 can be clamped between the plug part 2 and the screw connection part 4 in a form-fit and / or force-fit manner.

[0050] The pipe 10 has a nominal inner diameter NDI and a nominal outer diameter NDA. These fixed dimensions of the pipe determine its nominal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com