Anti-corrosion lining of dechlorination tank

An anti-corrosion lining and dechlorination technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as time-consuming, cost-increased, and dechlorination tanks are easily corroded and leaked, etc. Achieve short repair times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

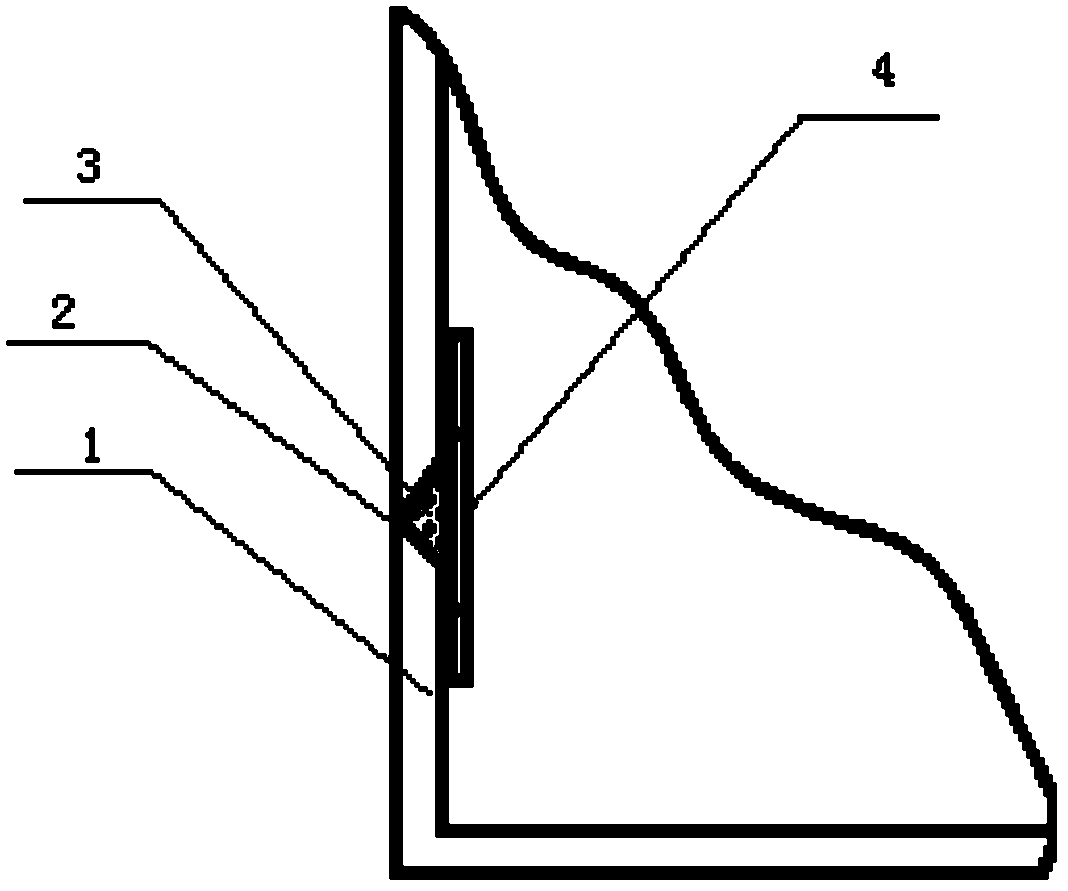

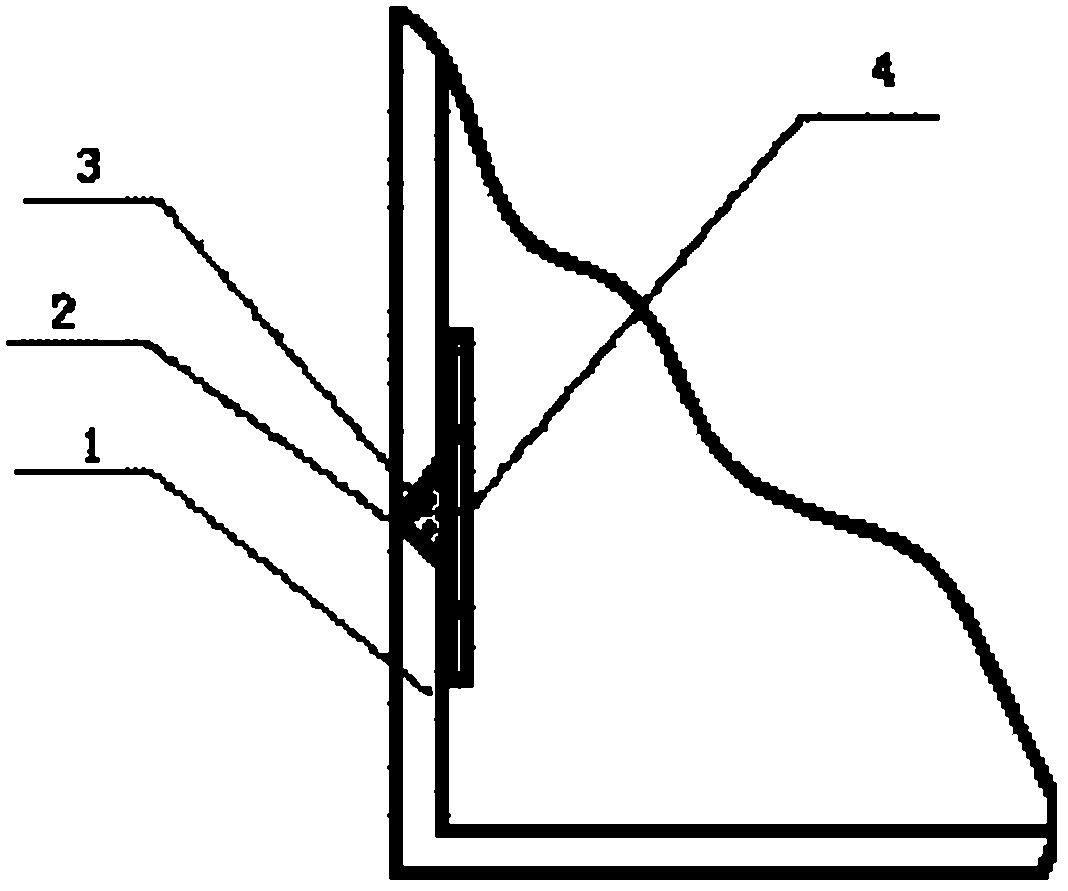

[0010] As can be seen from the accompanying drawings, the present invention comprises a dechlorination tank 1, a leak hole 2 is arranged on the said dechlorination tank 1, and potassium silicate cement 3 is provided in said leak hole 2 and peripheral positions, and said potassium silicate cement 3 There are 4 acid-resistant tiles on it. The potassium silicate cement 3 described above is arranged in the leakage hole 2, and is coated on the leakage hole 2 in the range of 30×30cm~50×50cm. The acid-resistant ceramic tile 4, the potassium silicate cement 3 and the dechlorination tank 1 are bonded into one body. After adopting the technical solution, the leakage is well repaired, and the cost is low and the effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com