Universal wheel convenient to disassemble and assemble and universal wheel set

A universal wheel and roulette technology, applied in the direction of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of production and sales, unsatisfactory use effect, increase production cost, etc., to simplify maintenance procedures, easy disassembly and maintenance. The effect of improving the efficiency of assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

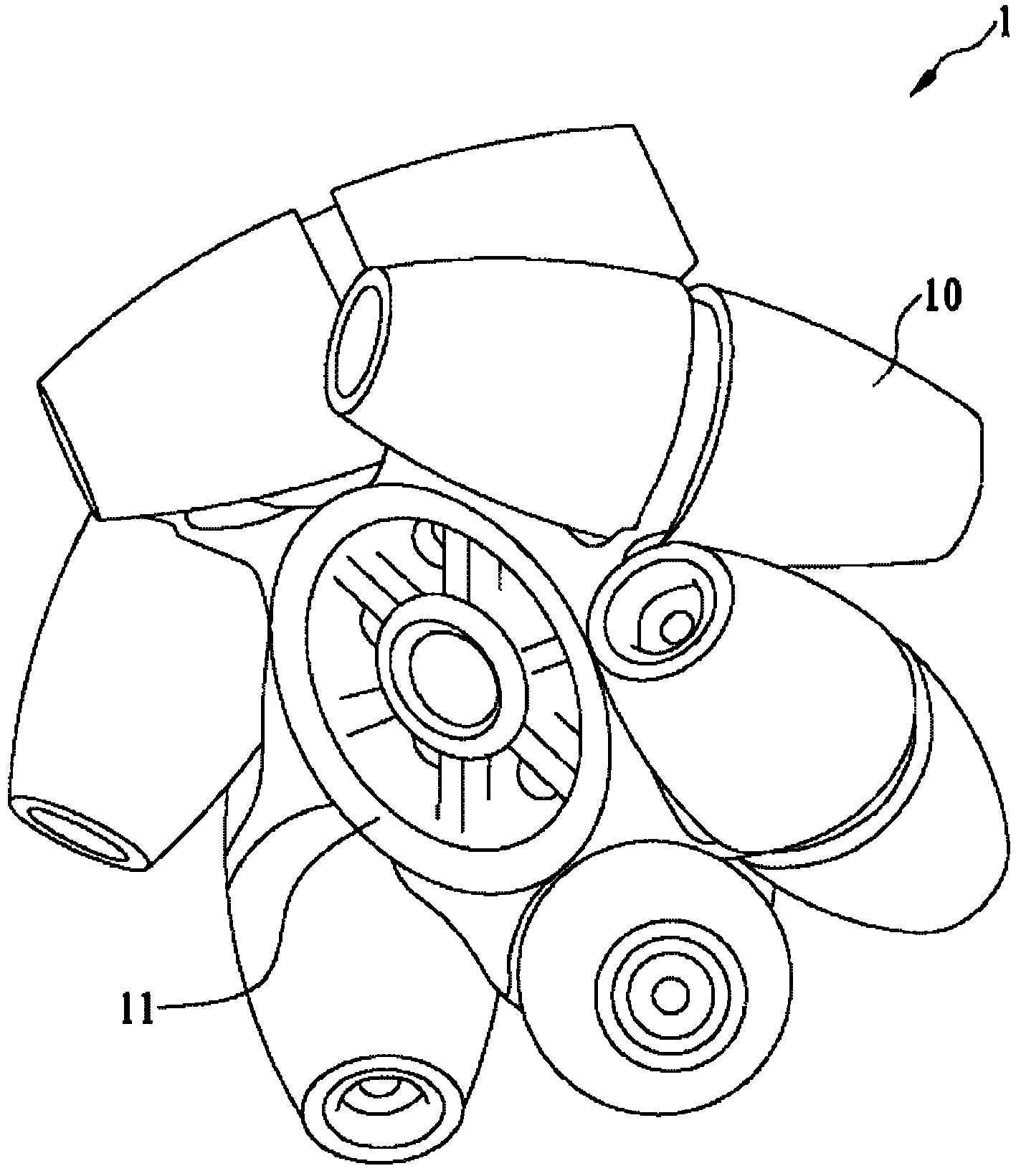

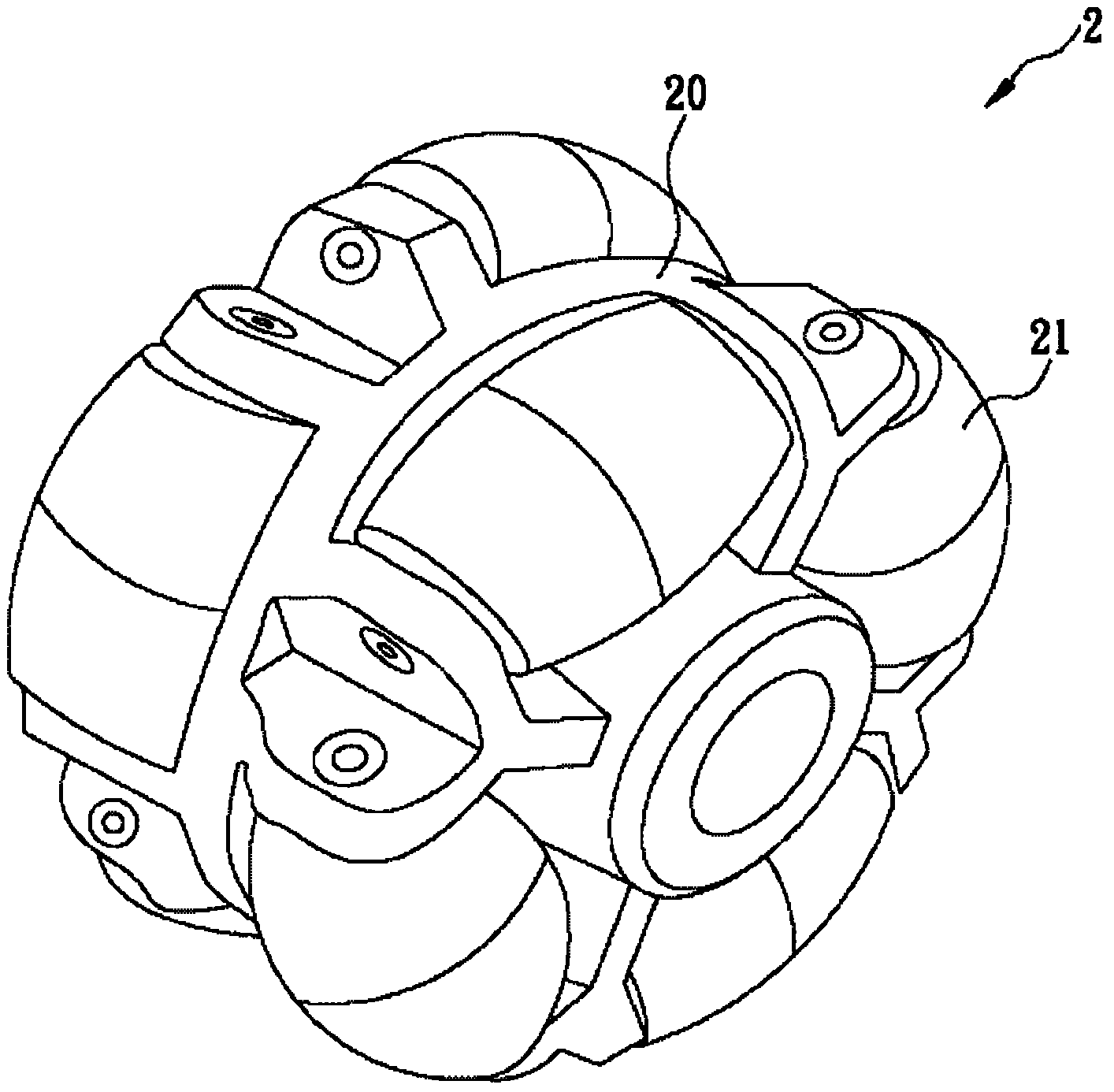

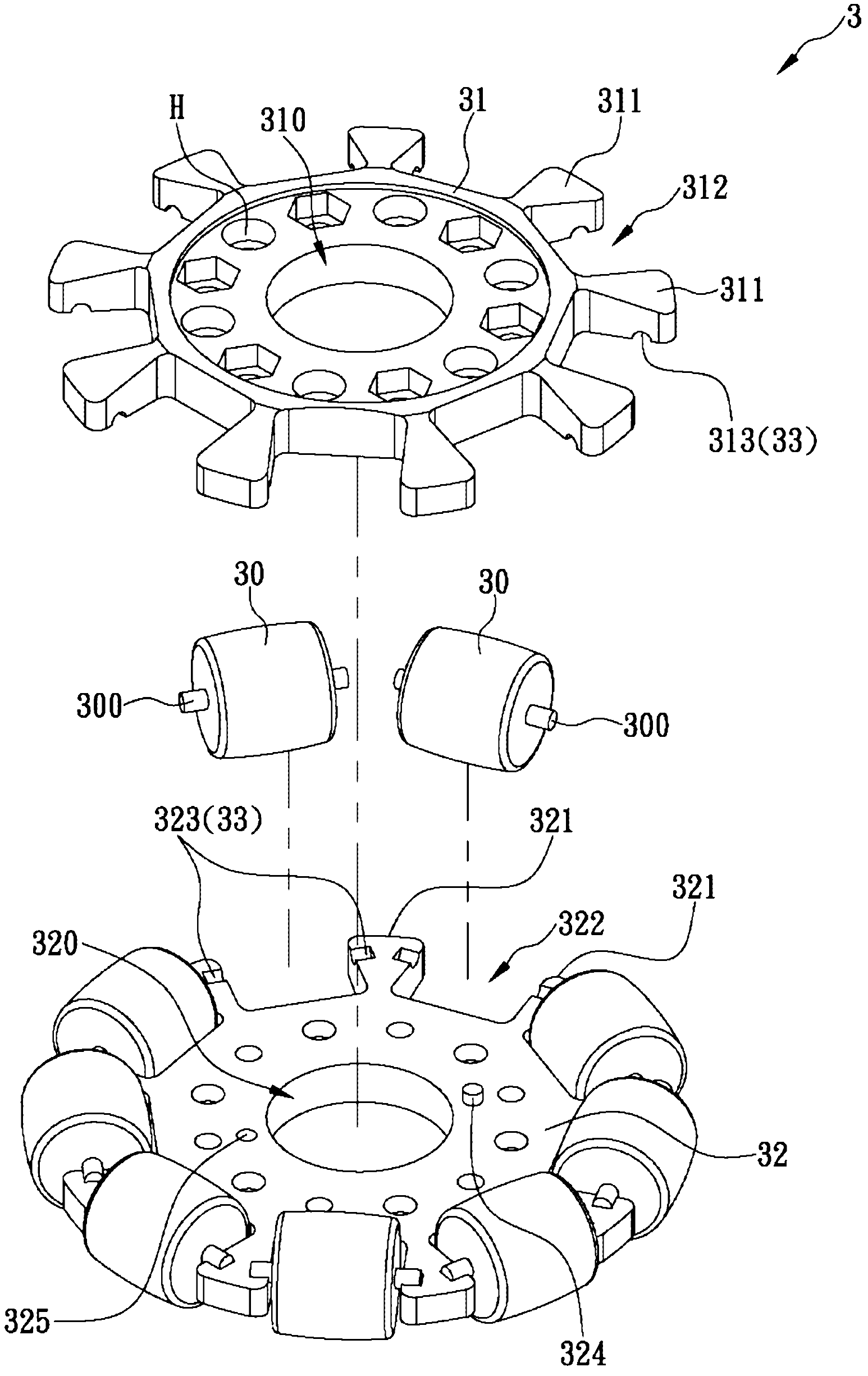

[0039] Such as image 3 As shown, the universal wheel 3 of Embodiment 1 of the present invention includes a plurality of rollers 30 and two disc bodies 31, 32, wherein the corresponding two ends of the rollers 30 are respectively extended with a pivot 300, and the rollers 30 can be made of rubber or other Made of elastic material. A through hole 310, 320 is provided in the center of each disc body 31, 32 for direct or indirect connection to a transmission shaft (not shown in the figure). In actual manufacturing, the manufacturer can use plastic and other materials to make the disc. Sheets 31, 32, but the present invention is not limited thereto. A plurality of protrusions 311, 321 protrude from the outer periphery of each disc body 31, 32 in the radial direction, and a housing space 312 is formed between adjacent protrusions 311, and adjacent protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com