Biological-based sheet for food contact and preparation method thereof

A food-contact, bio-based technology, applied in the field of polymer materials, can solve the problems of excessive hygienic indicators, no inspection reports of hygienic indicators, unsuitable for food-contact materials, etc., and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

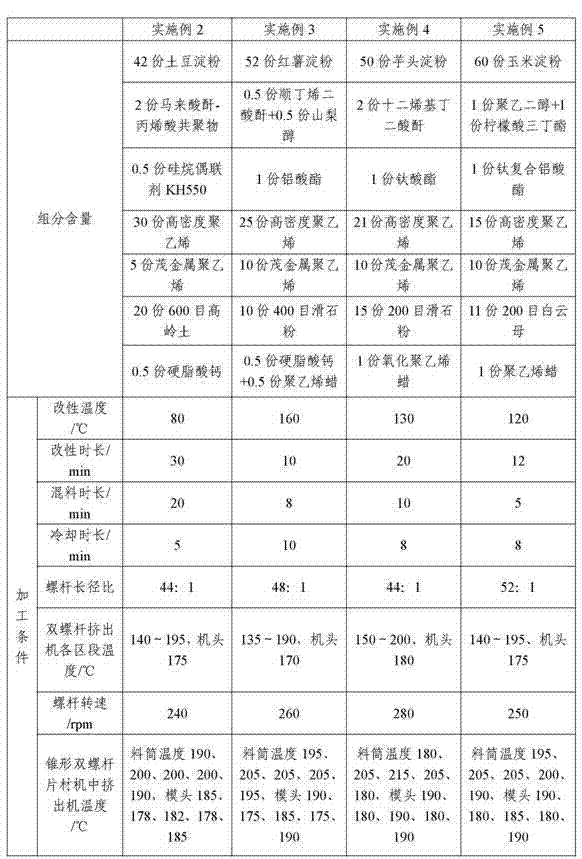

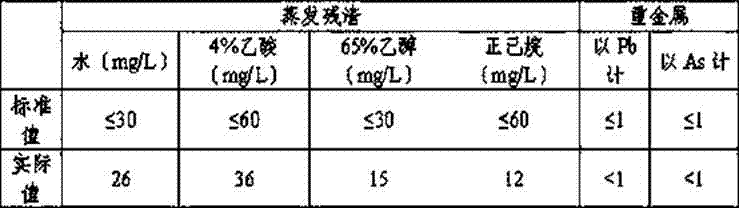

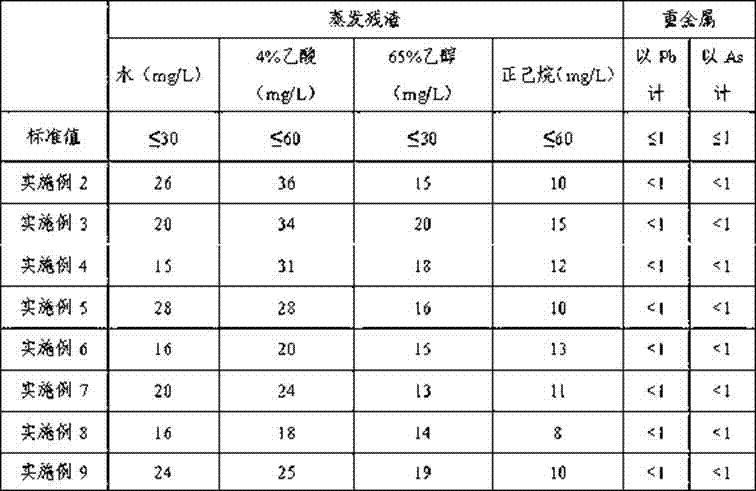

Examples

Embodiment 1

[0035] 40kg of cornstarch is ground and refined to 800 mesh through a pulverizer;

[0036] Add the refined starch into a high-speed mixer, then add 1kg of plasticizer and modifier sorbitol and 1kg of tributyl citrate, set the temperature to 100°C, stir for 5min, then add 1kg of coupling agent aluminate, Stir at high speed for 3 minutes;

[0037] Then add 30kg of high-density polyethylene, 10kg of metallocene polyethylene, 16kg of talcum powder, and 1kg of lubricant calcium stearate to the high-speed mixer, keep the temperature at 100°C, stir at high speed for 10 minutes, and prepare to discharge. At this time, the high-density polyethylene The surface of ethylene and metallocene polyethylene has been partially melted, and some powder materials adhere to the surface;

[0038] After the material comes out of the high-speed mixer, stir in the cold mixing pot at a low speed for 8 minutes, and wait for the material to cool to about 40°C;

[0039] Put the mixed material into the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com