Scaffolding guardrail

A scaffolding and guardrail technology, applied in the field of building construction equipment, can solve problems affecting smooth construction, efficiency, obstacles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

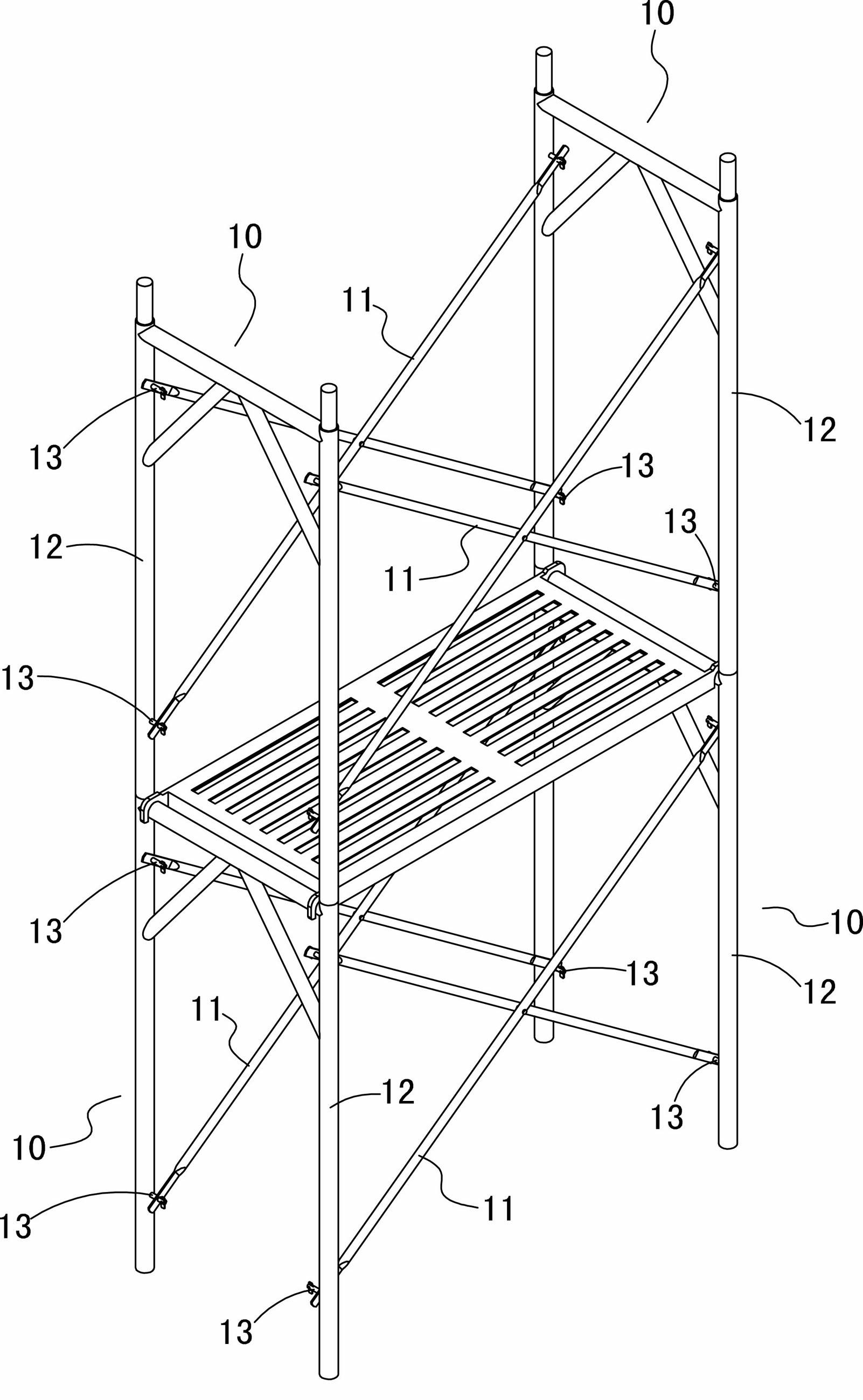

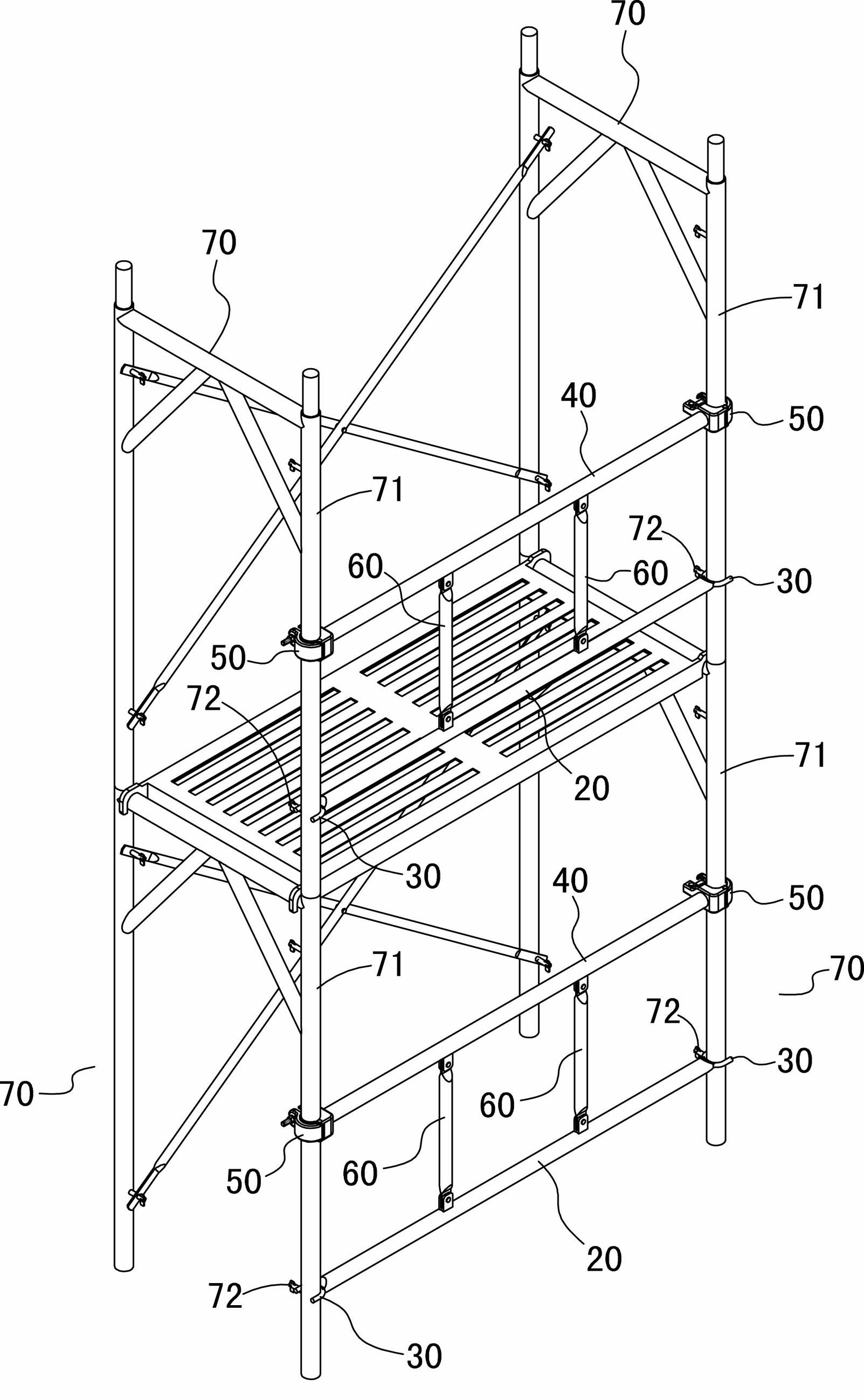

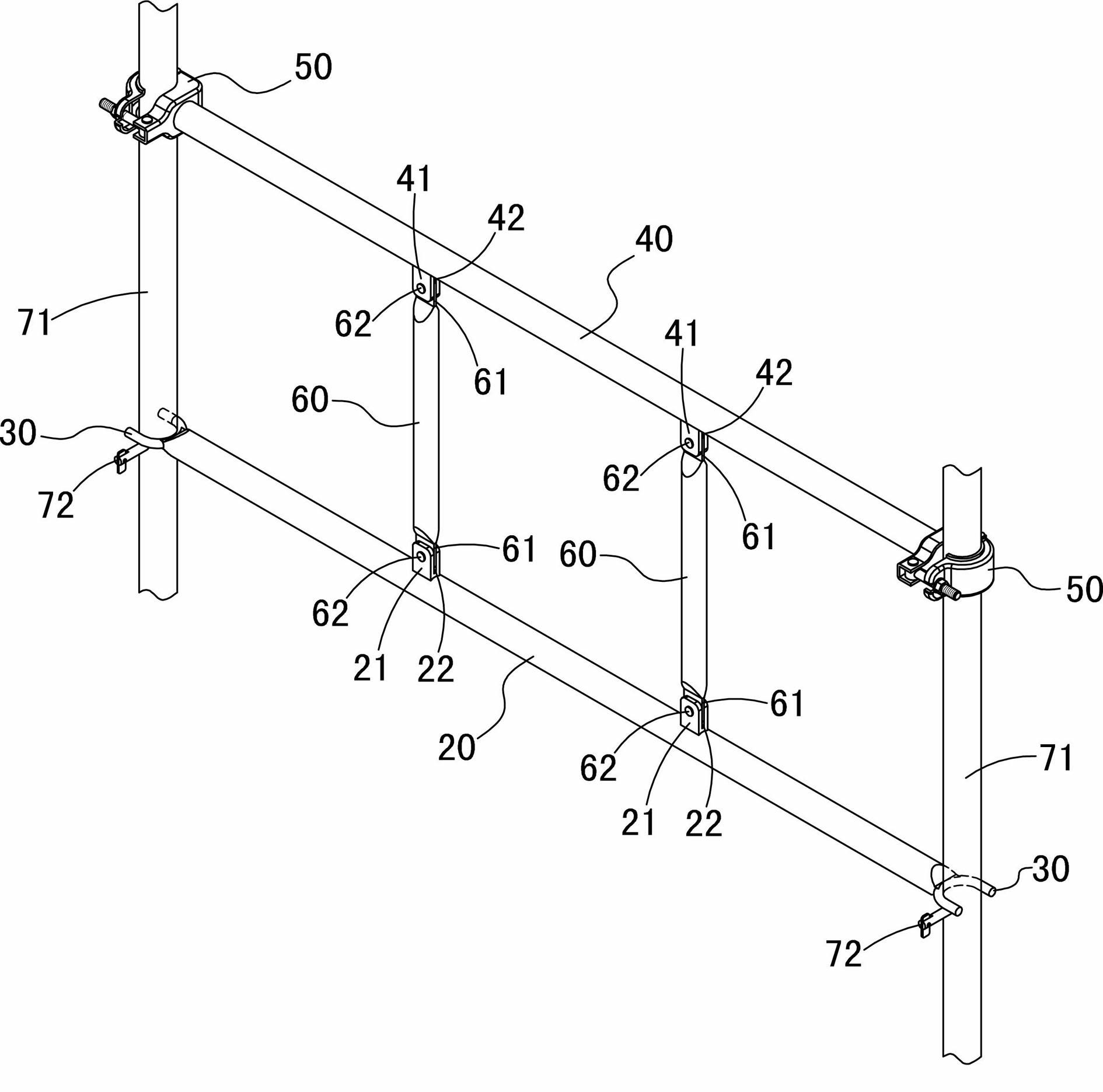

[0039] see Figure 2 to Figure 7 Shown is the first embodiment of the scaffold guardrail of the present invention, which indicates that the scaffold guardrail includes a lower cross bar 20 , two supports 30 , an upper cross bar 40 , two fasteners 50 and two connecting rods 60 . Wherein: the lower cross bar 20 is set horizontally. The two support members 30 are U-shaped respectively, and are combined with the two ends of the lower cross bar 20 respectively. The openings of the two support members 30 face outward, so that they can be forked on the same side of two adjacent scaffolds 70 respectively. On the vertical rod 71, and press on the upper side of the vertical rod 71 combined with the latch 72. The upper cross bar 40 is located directly above the lower cross bar 20 in parallel. The two fasteners 50 are respectively combined with two ends of the upper cross bar 40 , and the two fasteners 50 are respectively detachably fastened and fastened to the two upright bars 71 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com