Steel wire rope mesh tensioning device and method

A technology of steel wire mesh sheet and installation method, which is applied in the direction of erecting/assembling bridges, construction, processing of building materials, etc., to achieve the effect of improving specification quality and perfecting reinforcement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

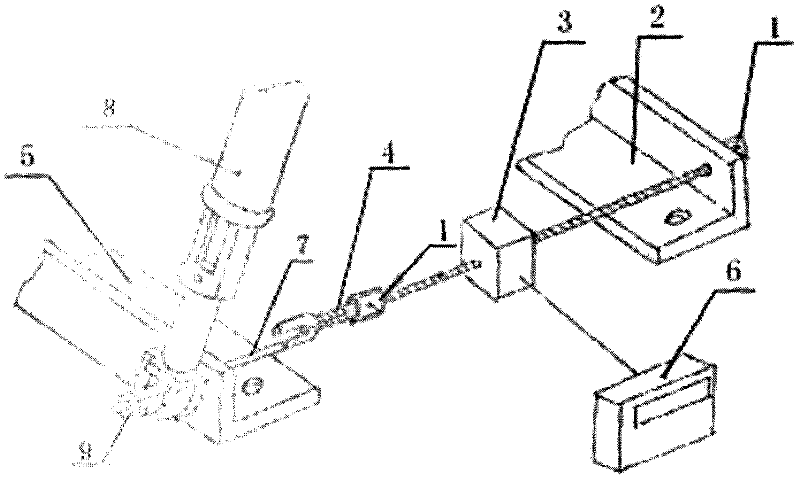

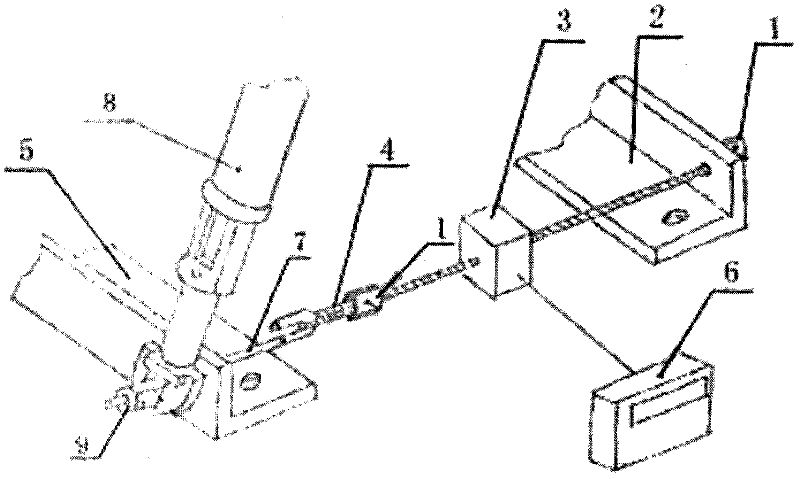

[0022] Example: such as figure 1 As shown, it is a tensioning wire rope mesh device, which includes a wire rope mesh 4, and one end of the steel wire rope mesh 4 is compressed and fixed at the fixed end 2 through an aluminum alloy joint 1. The other end of the wire rope mesh sheet 4 is fixed at the tension end 5 by a tensioner.

[0023] The tensioner includes a pull rod 7, a torque wrench 8, and a lock nut 9; one end of the pull rod 7 has a hook-shaped structure design, and is connected with the steel wire rope mesh 4 through an aluminum alloy joint 1, and the other end of the rod 7 is threaded and passes through the tensioner. The small hole on the end is engaged with the lock nut 9; the torque wrench 8 is located on the lock nut 9, and the lock nut 9 is tightened to realize the tensioning of the wire rope mesh 4 by the tensioner.

[0024] In order to measure the tension value of the steel wire rope mesh sheet 4, there is a tension sensor 3 in the middle of the steel wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com