Bearing with universal ball head

A universal ball head and bearing technology, applied in the direction of pivot connection, etc., can solve the problems that affect the safety of machinery, the ball head is not flexible enough to rotate, and the service life is short, so as to prolong the service life, solve the direct friction of the spherical surface, and reduce friction The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

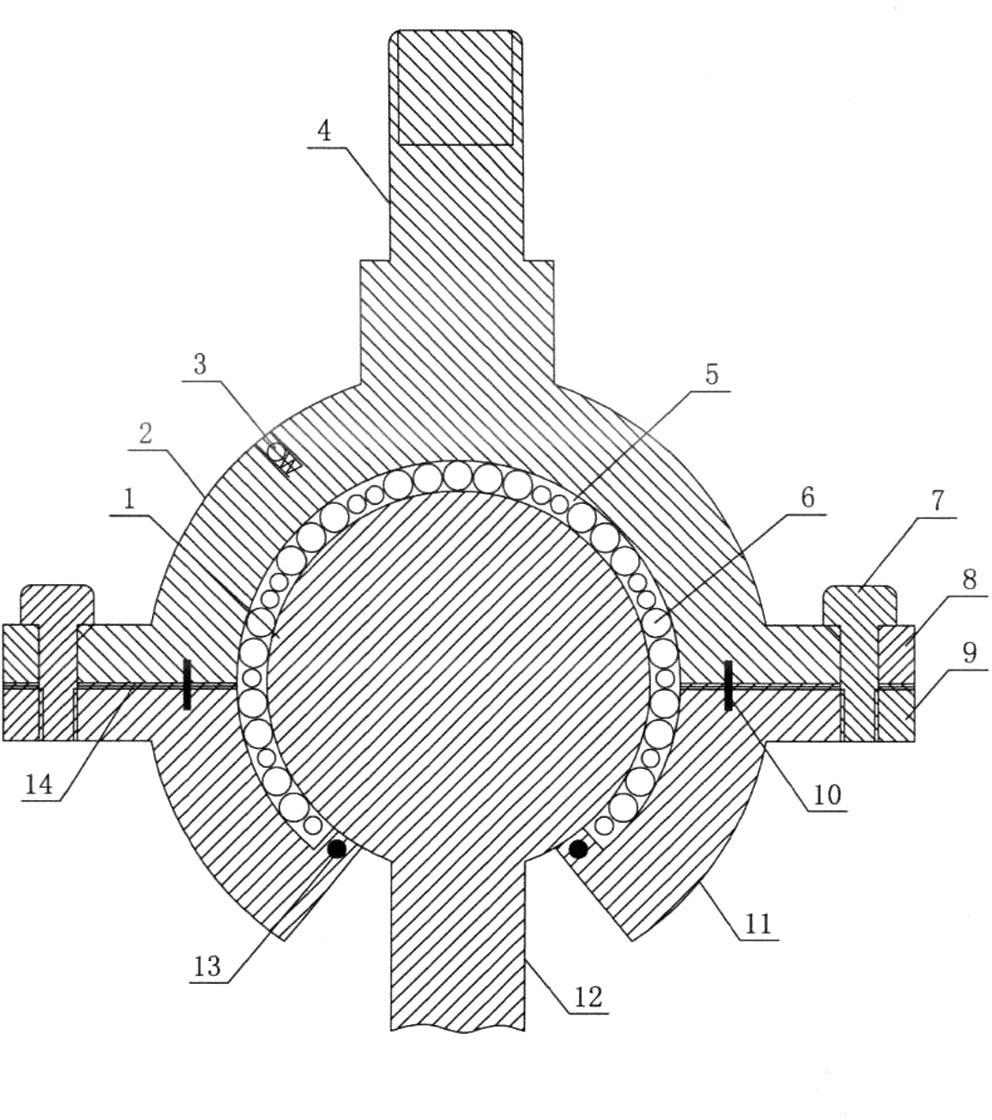

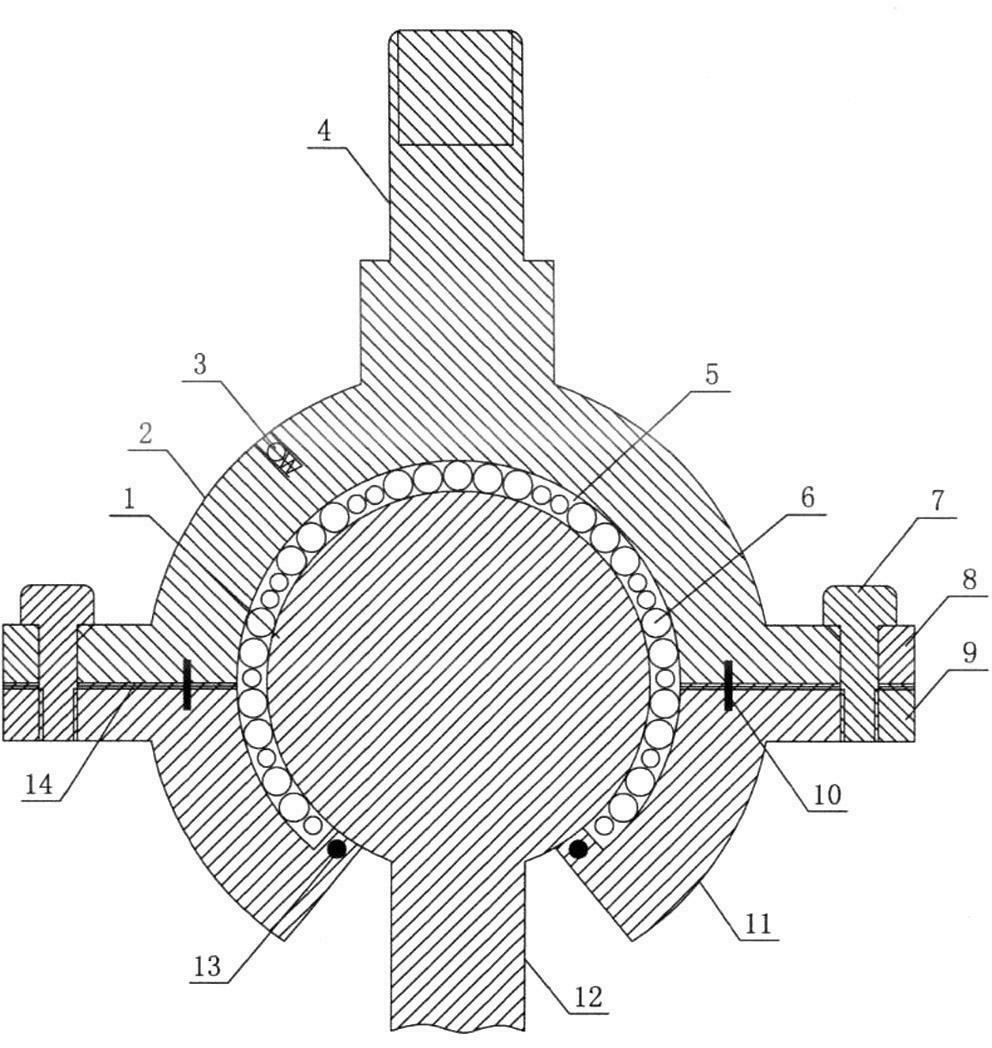

[0008] figure 1 The bottom end of the ball head 1 shown in the figure is provided with a ball head rod 12, and the outside of the ball head is provided with a ball shell, the ball shell is composed of an upper shell 2 and a lower shell 11, between the ball head 1 and the ball shell The circumference of the joint is provided with a circumferential inner cavity 5, and a circle of steel balls 6 is arranged in the circumferential inner cavity, the top of the upper housing is provided with a connecting base 4, and the bottom of the lower housing is provided with a sealing ring 13, and the upper and lower The left and right sides of the housing are provided with an upper connecting plate 8 and a lower connecting plate 9. Screw holes are provided on the upper and lower connecting plates. The upper and lower housings are fastened together by bolts 7. There are left and right two The positioning pin 10 is provided with an oil filling hole 3 on the upper left side of the upper housing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com