Off-axis aspheric lens detection method based on fringe reflection

An off-axis aspheric surface and detection method technology, which is applied in the field of advanced optical manufacturing and detection, can solve problems such as inability to obtain quantitative results, and achieve the effects of large dynamic measurement range, high sensitivity, and suppression of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

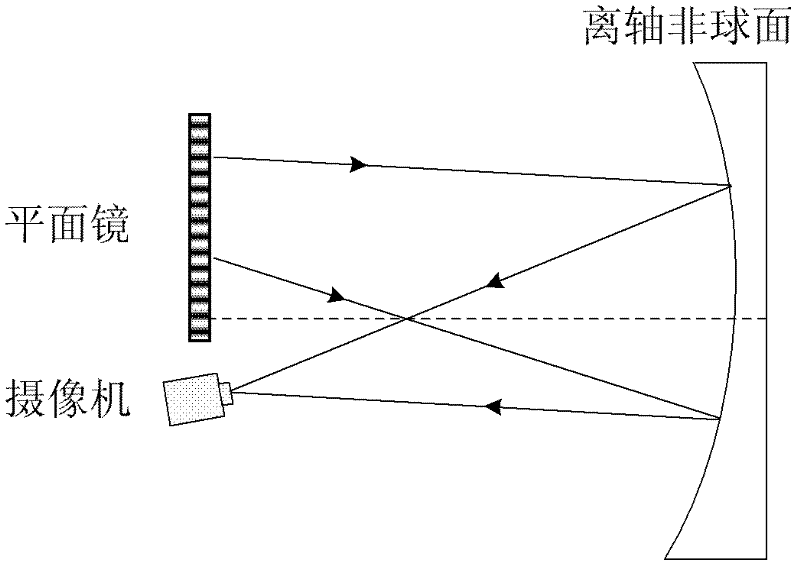

[0025] like figure 1 As shown, the measurement system consists of an off-axis aspheric mirror, a display screen and a CCD camera, such as figure 1 As shown, the implementation steps are as follows:

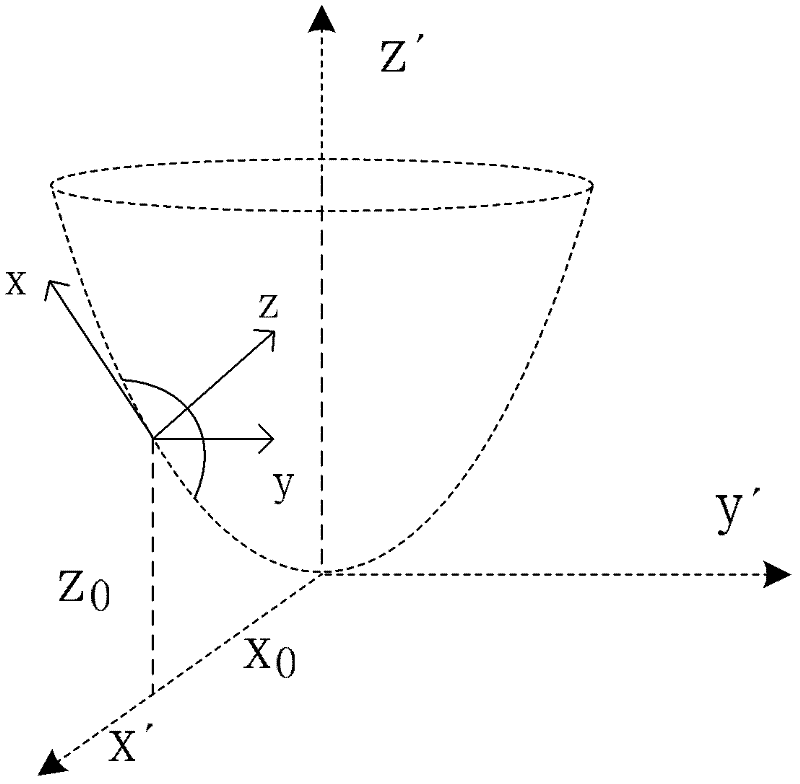

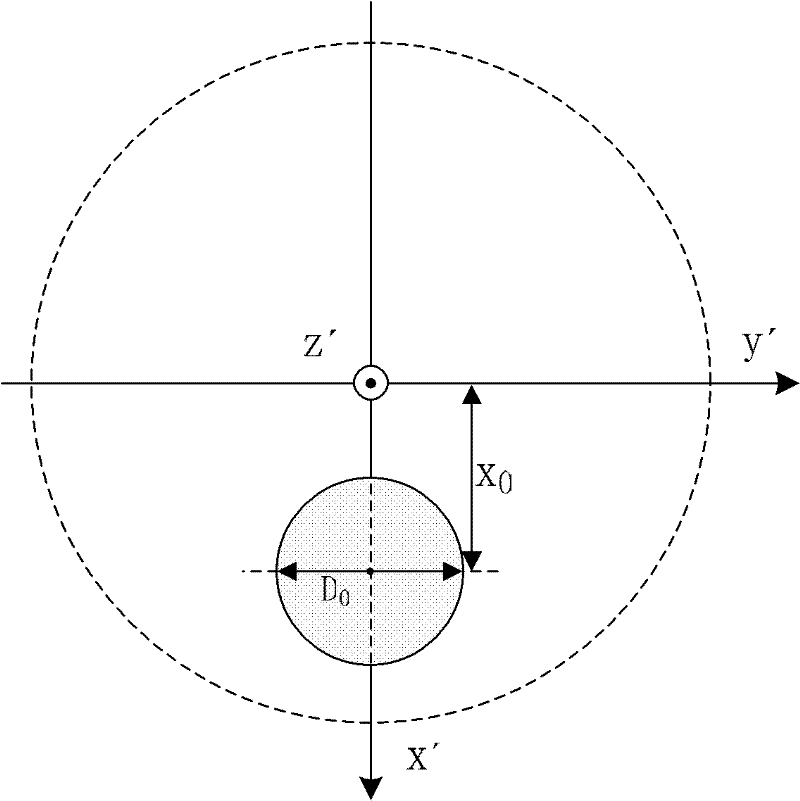

[0026] First, translate and rotate the mother mirror coordinate system to establish an off-axis non-plane world coordinate system. Generally, the equation of a symmetric quadratic aspheric mother mirror can be expressed as:

[0027] z ′ = c ( x ′ 2 + y ′ 2 ) 1 + 1 - ( k + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com