Atomatic transmission performance and fault detection apparatus and method thereof

An automatic transmission and fault detection technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of uneven maintenance personnel, multiple repairs, and complicated and difficult reasons for failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

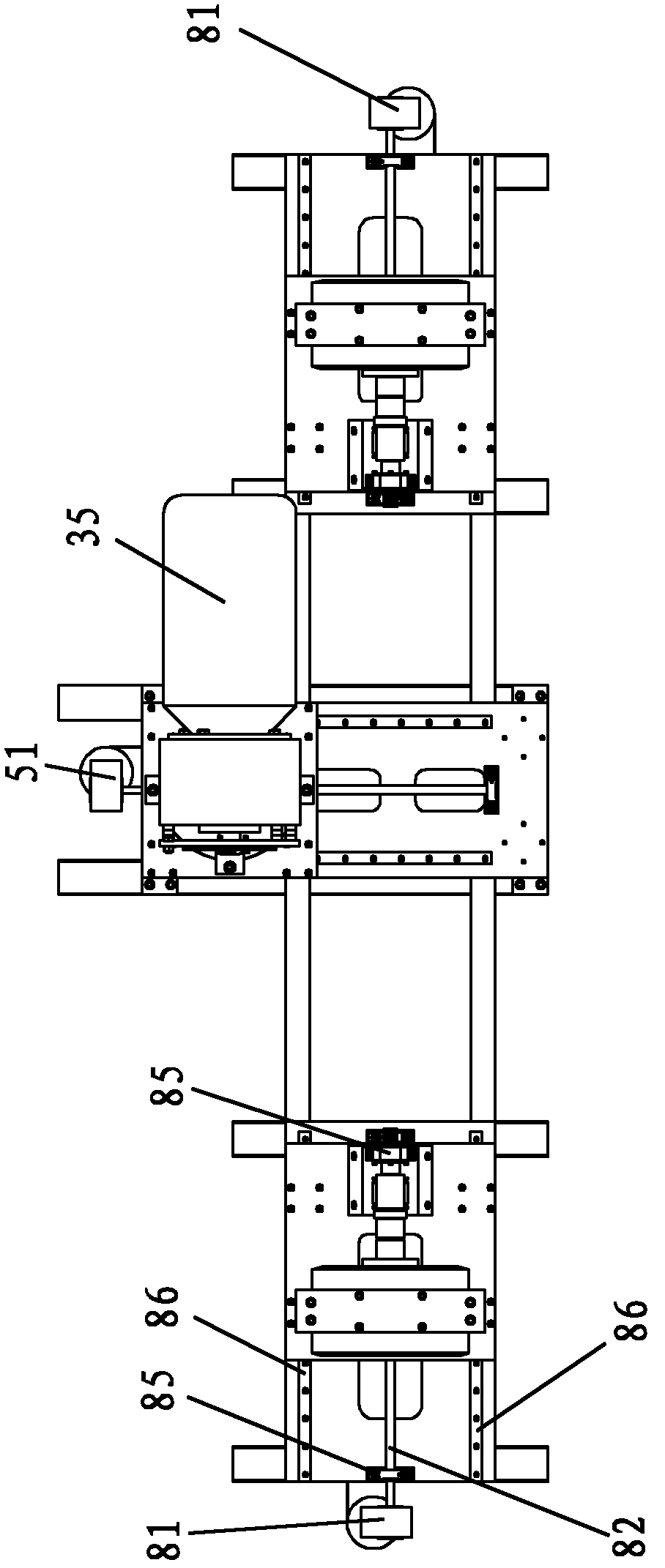

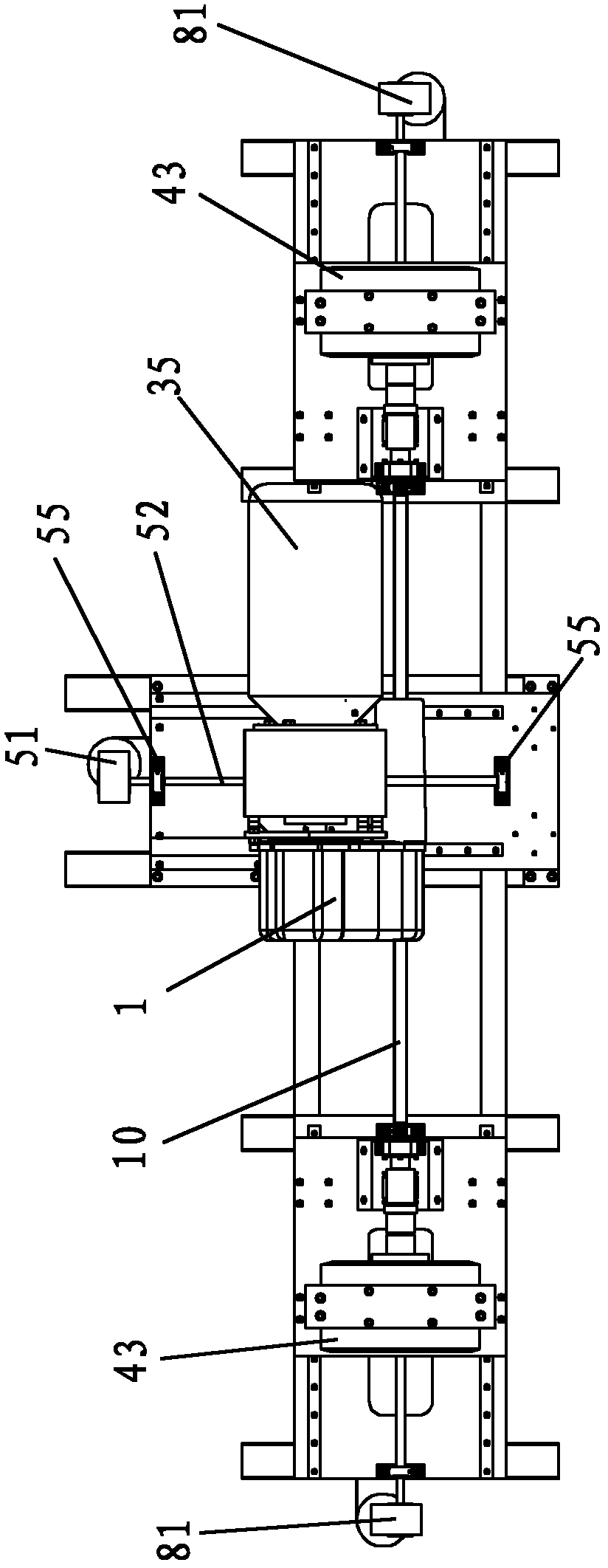

[0035] The automatic transmission performance and fault detection device and method of the present invention will be described in detail below with reference to the accompanying drawings.

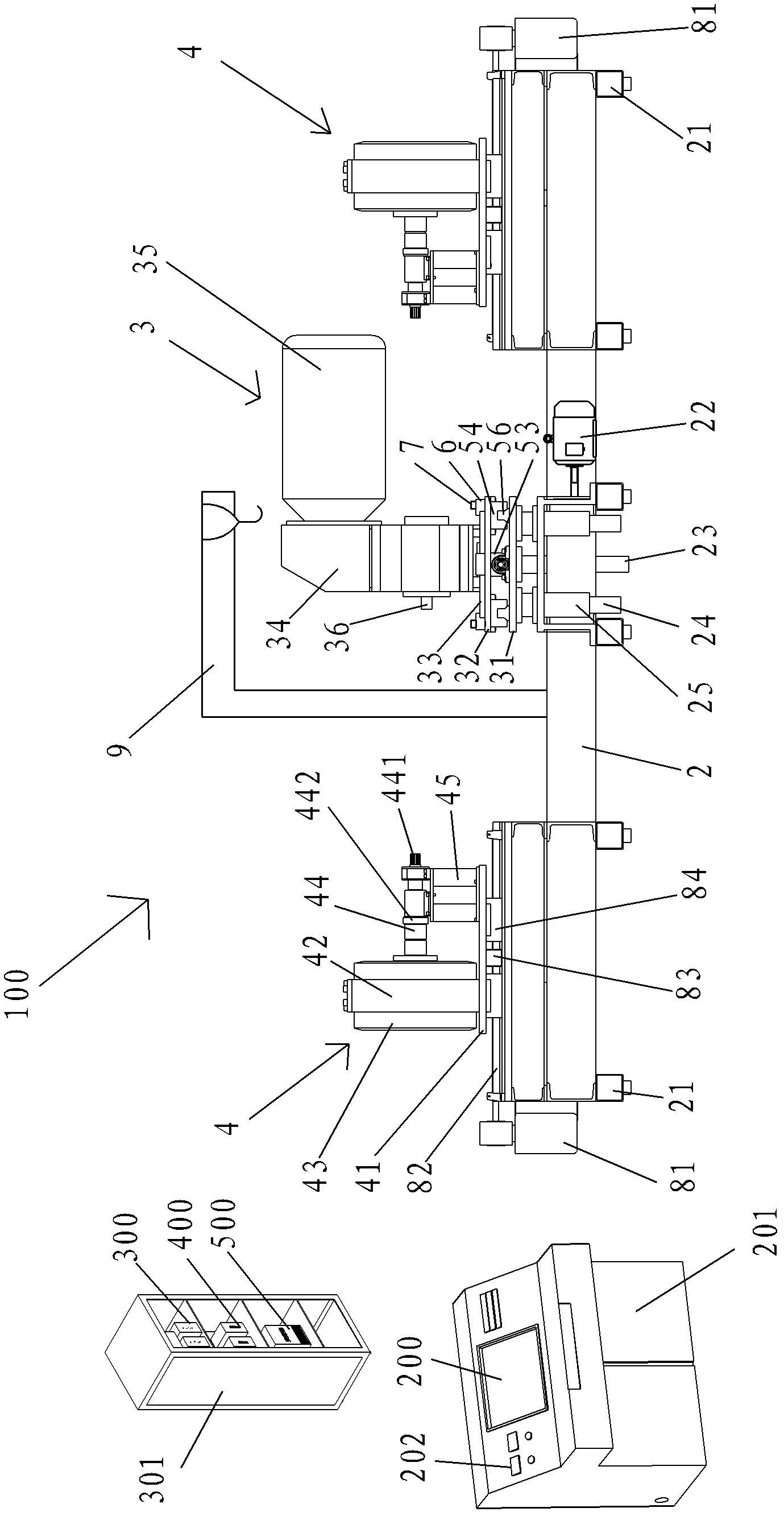

[0036] Such as figure 1 As shown, the automatic transmission performance and fault detection device of the present invention includes a test bench 100 for positioning the self-transmission 1 , a control terminal, multiple relays 300 , a frequency converter control module 400 , and a loading control module 500 .

[0037]In this embodiment, the control terminal is a computer 200, and control software is pre-installed in the computer 200, and the control software also includes various theoretical values of the automatic transmission in different states, and the computer 200 is set In a cabinet 201; the plurality of relays 300, the frequency converter control module 400, and the loading control module 500 are all placed in an electrical cabinet 301, and a plurality of display instruments (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com