Electric automobile motor installation carriage

A technology for mounting brackets and electric vehicles, applied to electric vehicles, motors, electromechanical devices, etc., can solve problems such as instability, movement of square bars, limitations, etc., and achieve the effects of simple structure, simple installation, and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to understand the technical content of the present invention more clearly, the following embodiments are given for detailed description. Wherein the same parts bear the same reference numerals.

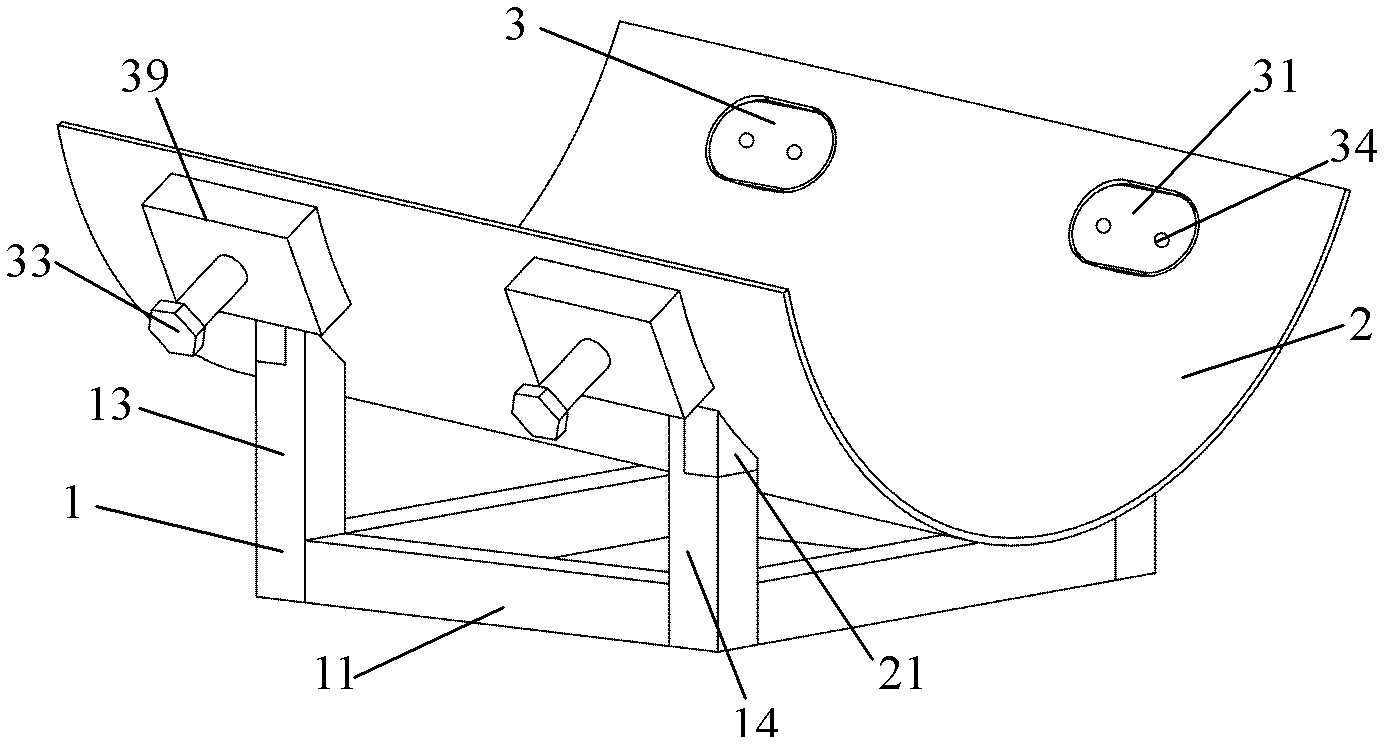

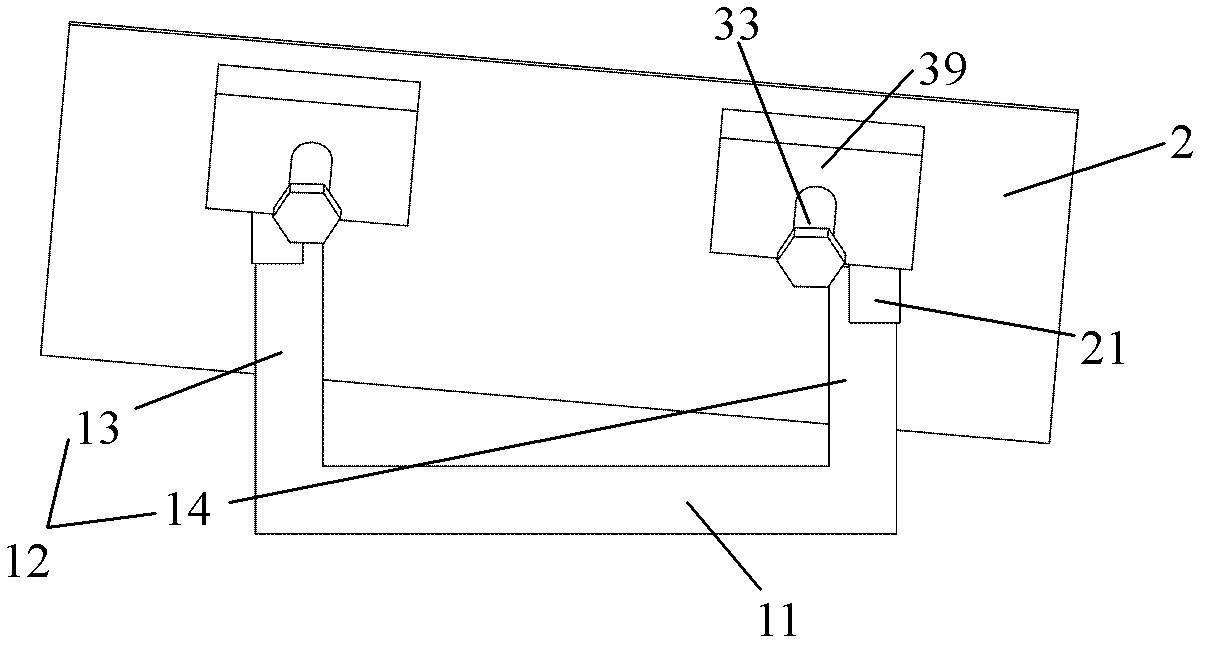

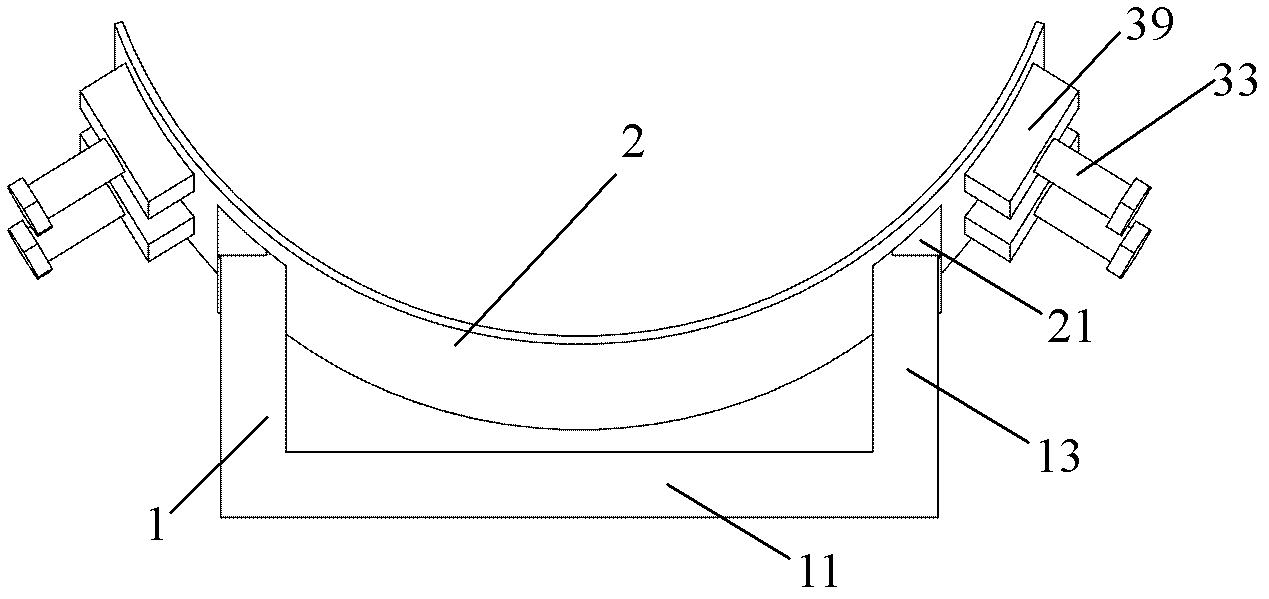

[0031] See Figure 1-10 As shown, the electric vehicle motor mounting bracket of the present invention includes a lower support bracket 1 and an upper motor bearing bracket 2, the upper motor bearing bracket 2 is slantingly supported on the lower support bracket 1, and the upper motor bearing bracket 2 A motor fastening part 3 is provided in the middle.

[0032] The positioning of the upper motor carrying bracket 2 and the lower support bracket 1 may be in any suitable manner, such as welding, plugging or screwing, and the like. See Figure 1-3 As shown, in the specific embodiment of the present invention, the lower part of the upper motor carrying bracket 2 is provided with a fixed support 21, and the fixed support 21 is sleeved on the lower support bracket 1 to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com