Method for sterilizing cucumber juice

A cucumber juice and sensory technology, which is applied in the field of cucumber juice sterilization, can solve the problems of difficulty in meeting the hygienic requirements of fruit and vegetable juice beverages and limited sterilizing ability, and achieve the effects of improving the bactericidal effect, improving the bactericidal effect, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, a kind of sterilization method of cucumber juice, carries out following steps successively:

[0013] 1) Store freshly squeezed cucumber juice at -18°C for 24 to 48 hours;

[0014] 2), naturally thawing the product of step 1) to a liquid state to obtain thawed cucumber juice;

[0015] 3), keeping the thawed cucumber juice under the ultra-high pressure of 400-600Mpa for 10-20 minutes.

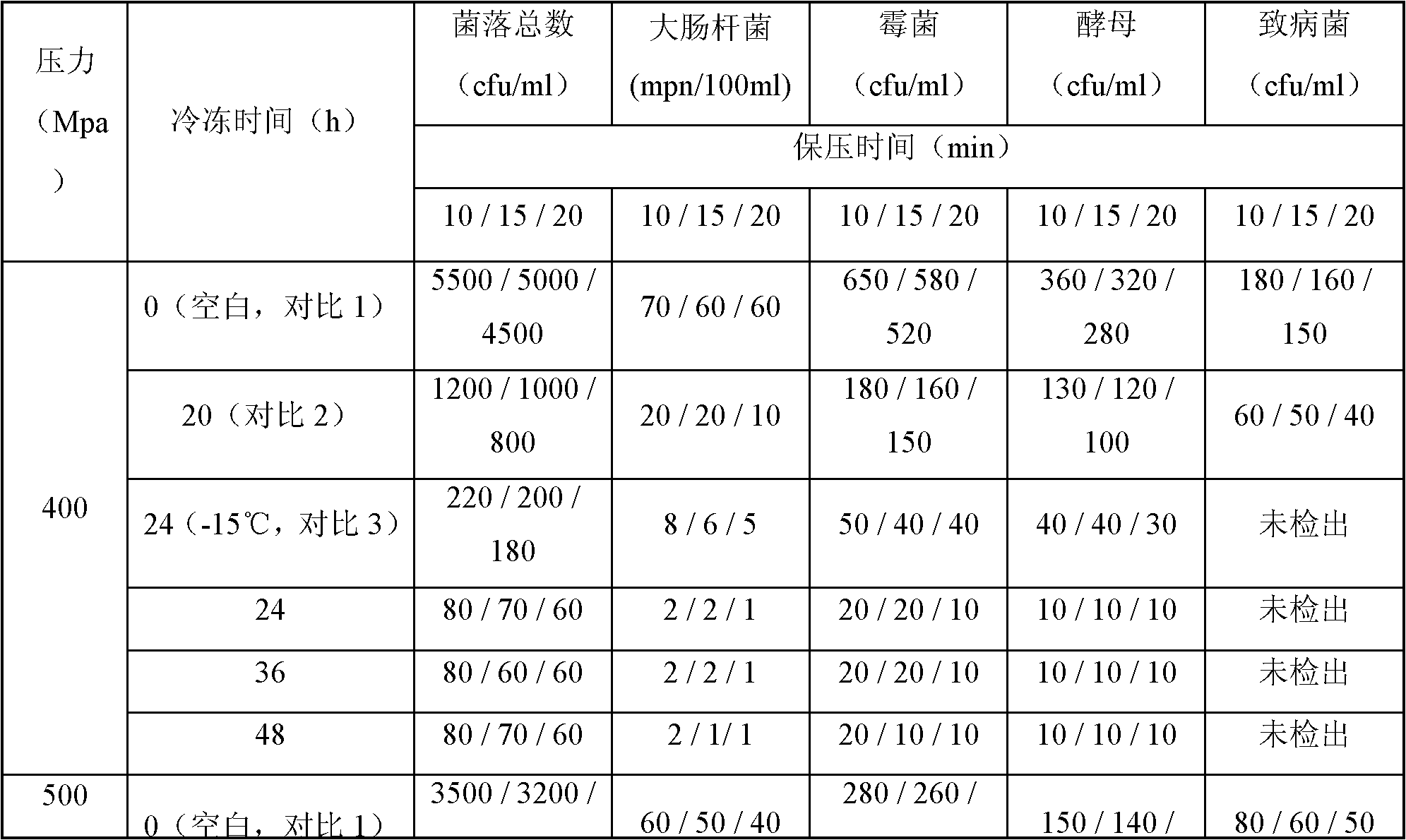

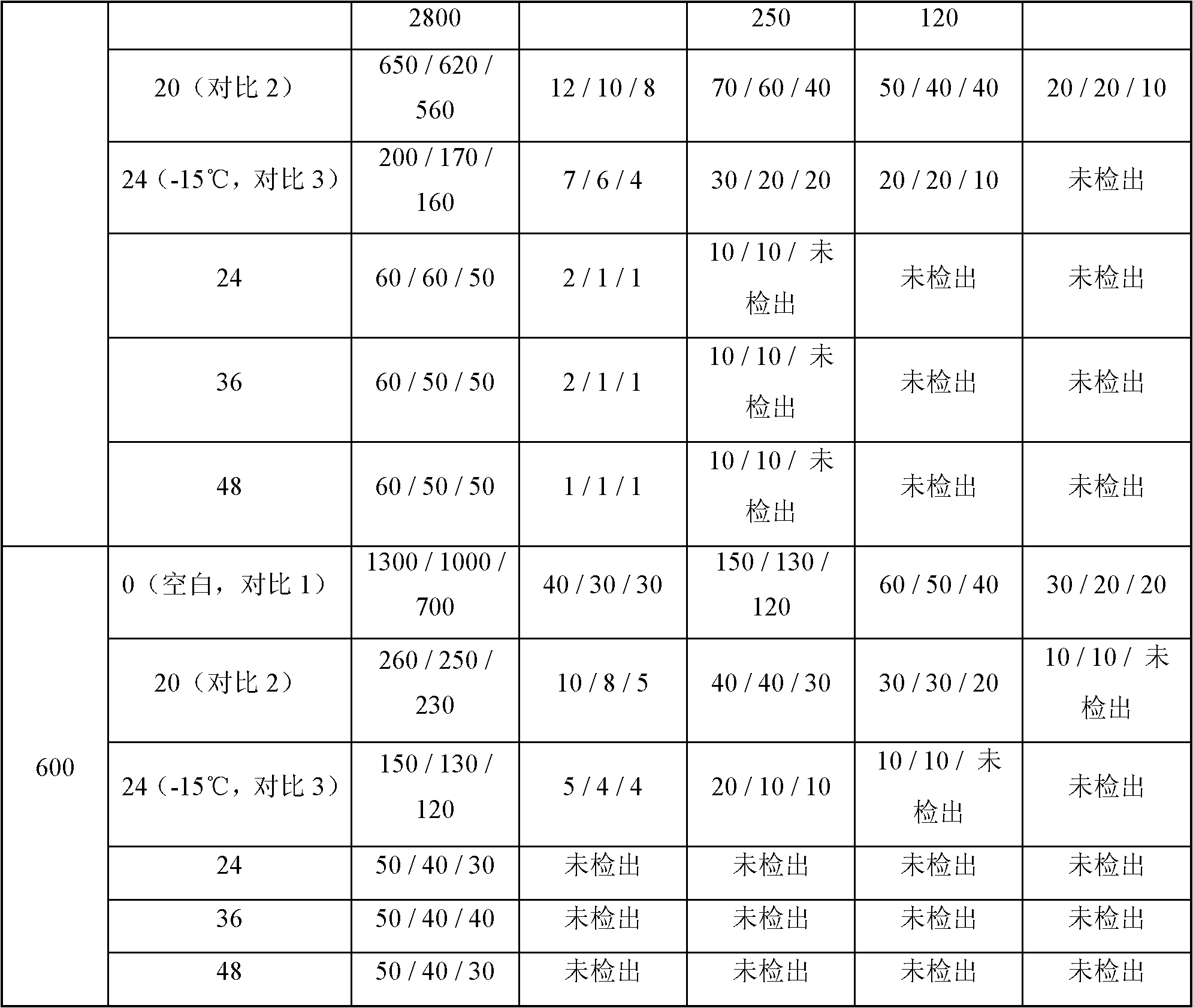

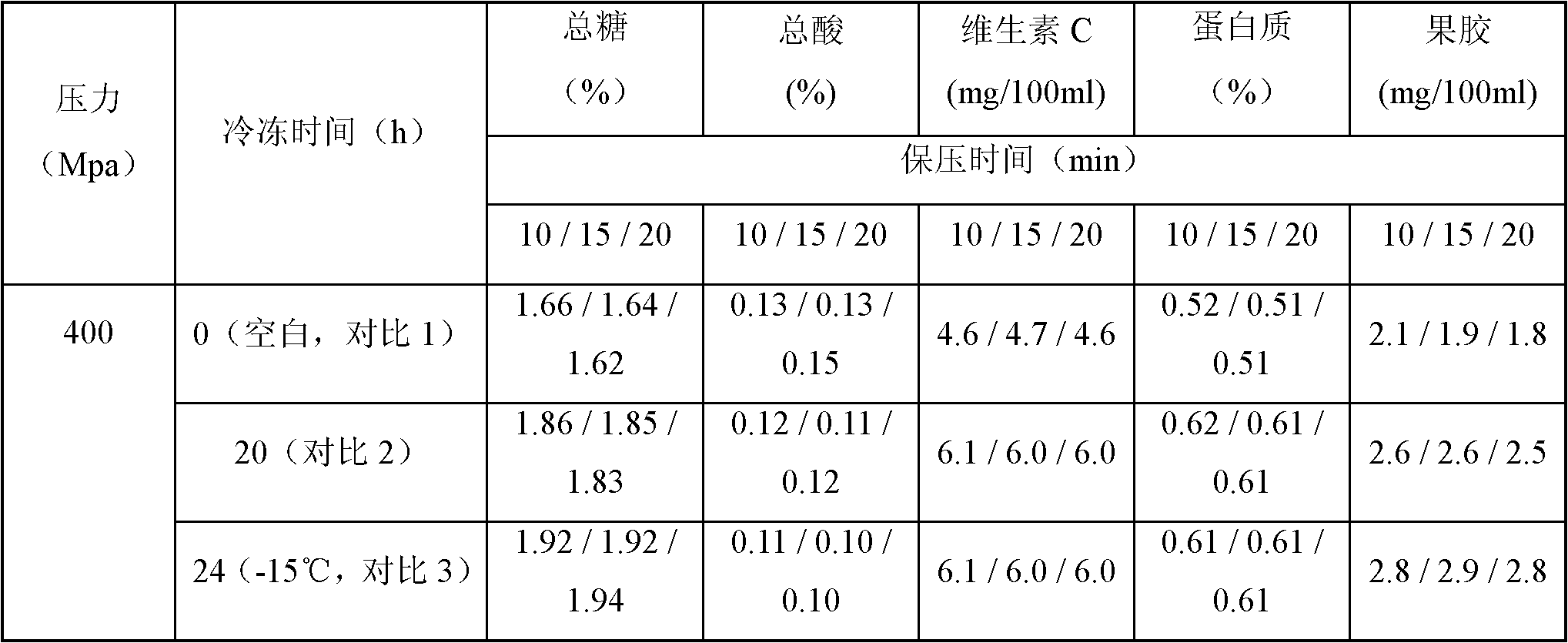

[0016] In order to prove the bactericidal effect of the present invention and the effect of maintaining the nutritional quality of the product to the greatest extent, the inventor changed the freezing temperature and freezing time as a comparative example; the specific results are shown in Table 1, Table 2 and Table 3.

[0017] Note: Except that the freezing temperature of comparison 3 is -15°C, the others are -18°C.

[0018] Table 1 Microbial residues of cucumber juice after freezing pretreatment at -18°C under different pressures and after different holding times (the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com