High-temperature high-pressure soymilk machine

A high temperature and high pressure, soy milk machine technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of inconvenient cleaning, bulky machine head, corrosion of motor circuit control devices, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

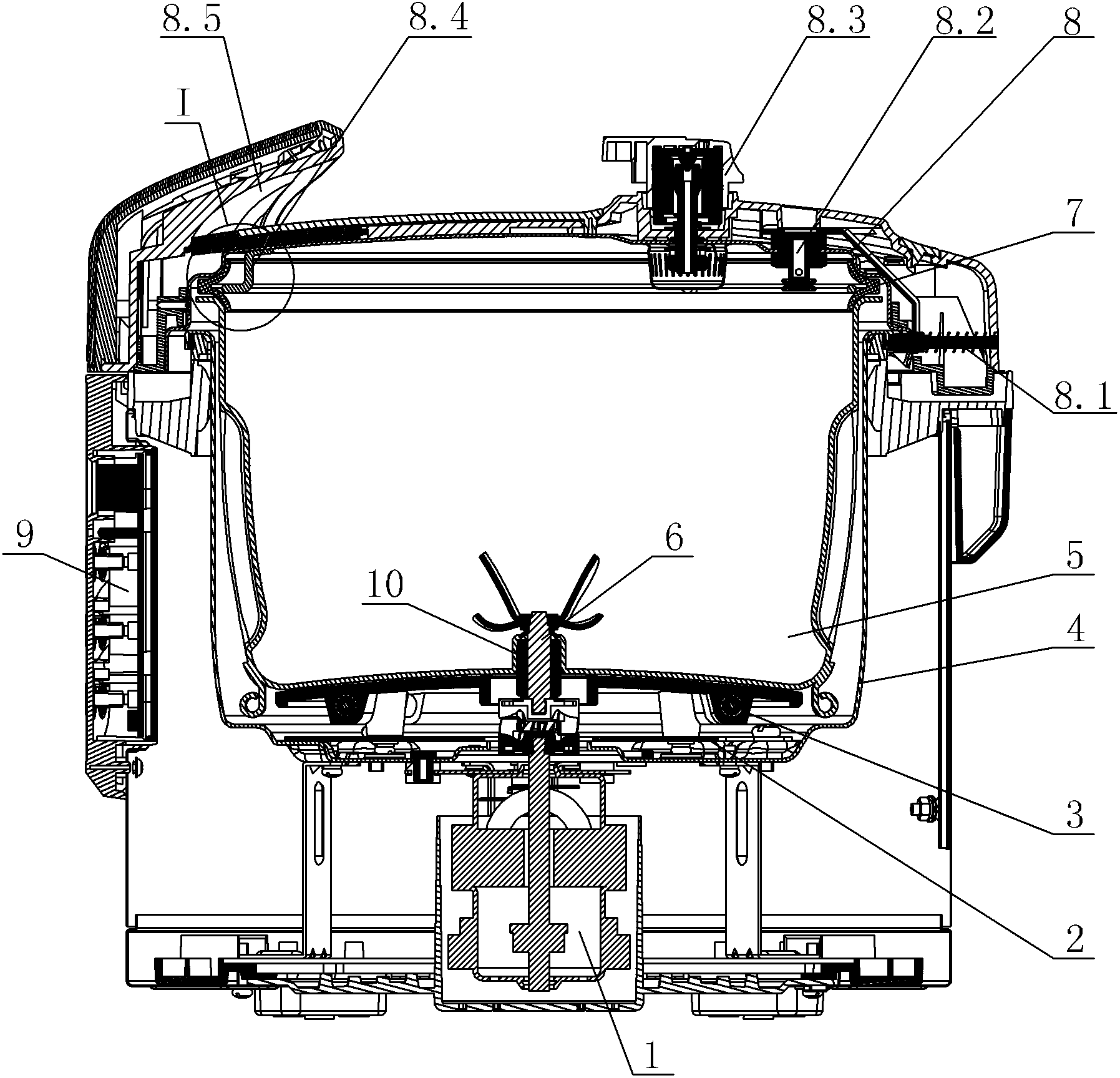

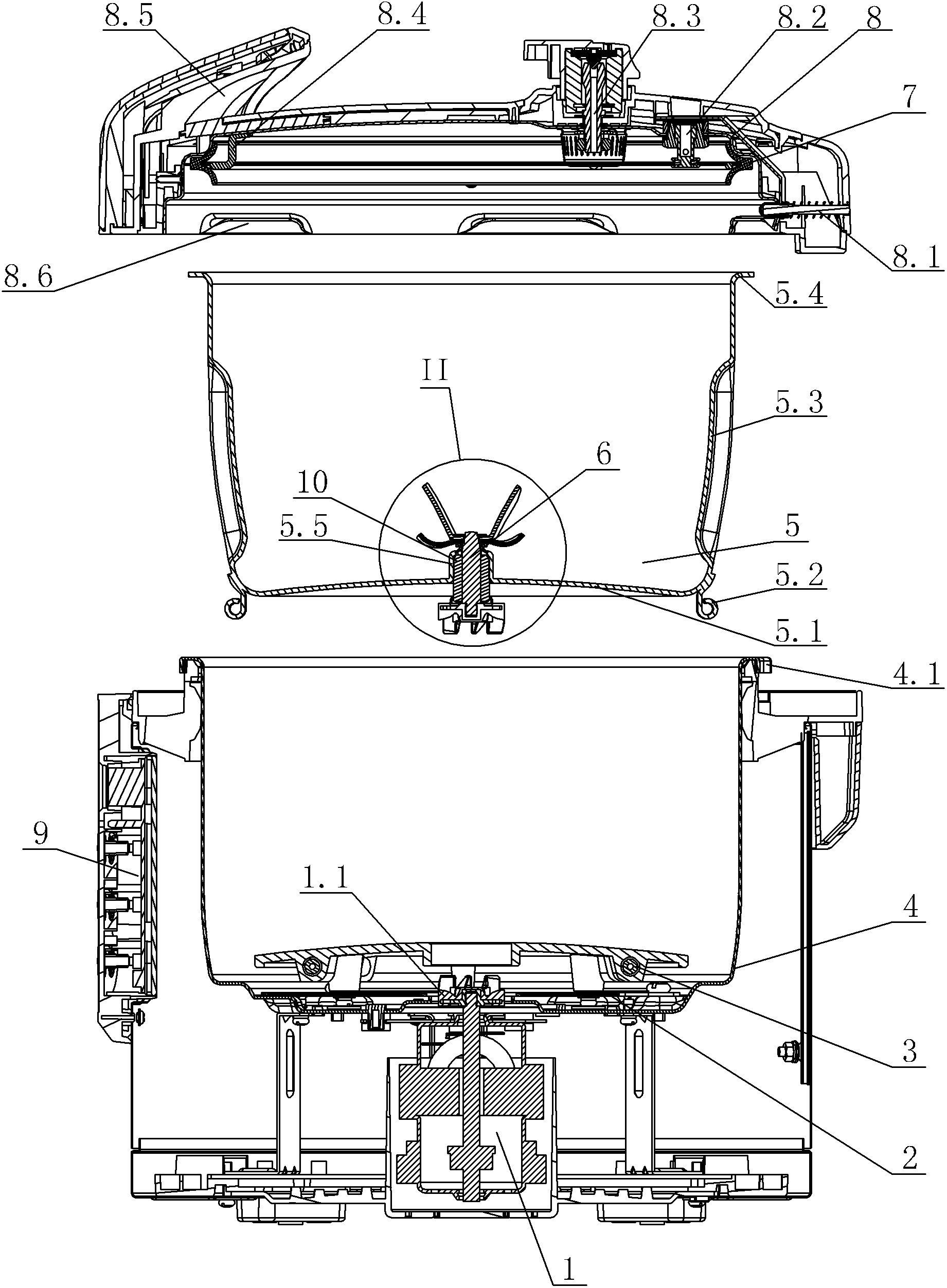

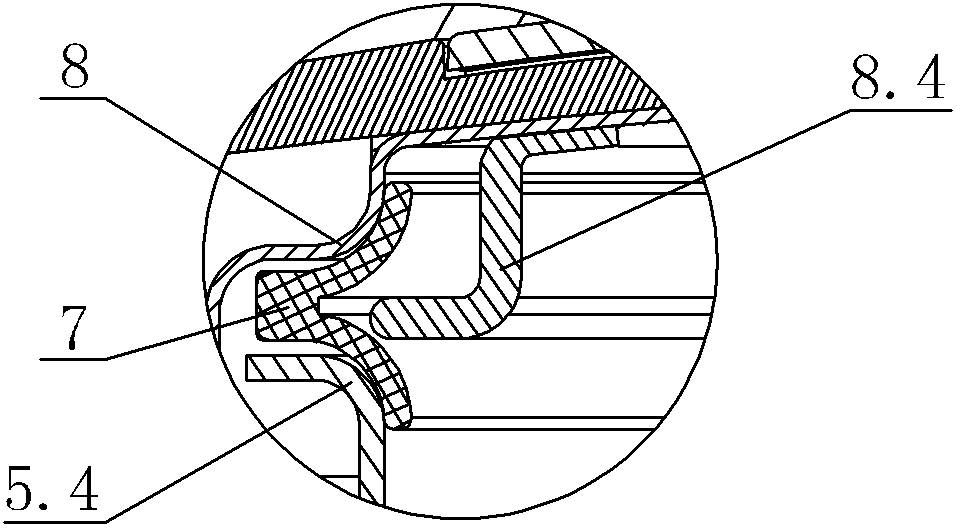

[0019] see Figure 1-Figure 5 , a high-temperature and high-pressure soybean milk machine, comprising an outer pot 4, an inner pot 5, a control panel 9, a motor 1 arranged in the fuselage, a heating device 3 and a pot cover assembly 8 installed on the upper part of the fuselage, and the inner pot 5 can be Take it out from the outer pot 4, the pot cover assembly 8 is sealed with the upper edge 5.4 of the inner pot through the sealing ring 7, the bottom 5.1 of the inner pot is provided with a pulverizer device 6, and the motor 1 drives the pulverizer device 6 through a clutch; the heating device 3 contacts the inner pot Bottom 5.1 or inner pot side wall and heat it.

[0020] The heating device 3 is fixed on the elastic plate 2, and the elastic plate 2 is fixed on the outer pot 4, and the outer pot 4, the heating device 3, the elastic plate 2, the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com