A bioenzyme sensor implantable in human body and its manufacturing method

A production method and bio-enzyme technology, applied in sensors, medical science, diagnostic recording/measurement, etc., can solve the problems of outer membrane layer adhesion, biocompatibility and protein resistance, and achieve good protein adsorption resistance , excellent mechanical elasticity, easy preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

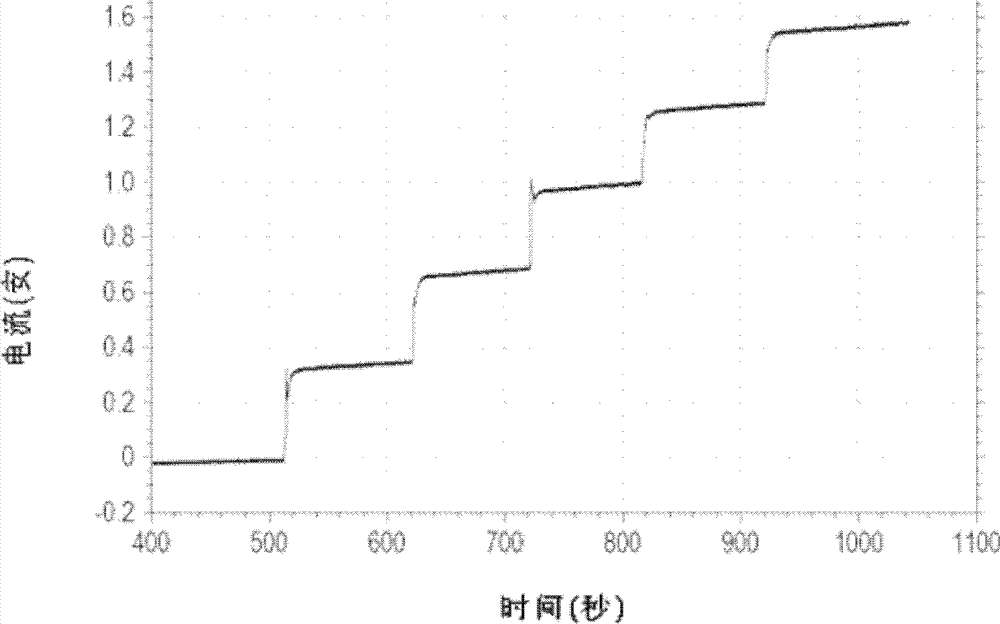

Embodiment 1

[0044] 1. Polish the stainless steel needle with 300-grit sandpaper, and decorate a layer of platinum black on the substrate after degreasing, activation and electroplating tools; 2. Use polyvinyl alcohol as a carrier to embed glucose oxidase and polythioalkyd resin In the electrode, dry at room temperature; 3, the excess (n NCO :n NH2 / OH / SH The value is controlled at 1.3) of 4,4'-dicyclohexylmethane diisocyanate (HMDI) reacts with polyester diol and polysiloxane, and adds a small amount of dibutylamine to generate polyurethane prepolymer, and the reaction time is After 10 hours, the reaction temperature was 45°C. After the reaction, it was purified by liquid phase preparative chromatography. The prepolymer was modified on the enzyme layer by dip coating, and then cured by heat to form a film. The prepared biosensing layer had good adhesion. It does not fall off in animal or human long-term tests, and has good biocompatibility and anti-protein adsorption performance.

[0045...

Embodiment 2

[0047] 1. Polish the titanium wire with 400-mesh sandpaper, and decorate a layer of gold on the substrate after degreasing, activation and electroplating tools; 2. Using hydroxycellulose as a carrier, embed glucose oxidase and agarose in the electrode, Dry at room temperature; 3, the excess (n NCO :n NH2 / OH / SH The value is controlled at 1.4) isophorone diisocyanate (IPDI) reacts with polyether diol and polysiloxane, and adds a small amount of 1,4-butanediol to generate polyurethane prepolymer, and the reaction time is 8 Hours, the reaction temperature is 55 ° C, after the reaction, it is purified by liquid phase preparative chromatography. The prepolymer is modified on the enzyme layer by spraying, and then cured by ultraviolet light to form a film. The prepared biosensing layer has good adhesion. It does not fall off in animal or human long-term tests, and has good biocompatibility and anti-protein adsorption performance.

[0048] According to the bioenzyme sensor that can ...

Embodiment 3

[0050] 1. Polish the aluminum wire with 300-mesh sandpaper, and decorate a layer of platinum black on the substrate after degreasing, activation and electroplating tools; 2. Using polyacrylamide as a carrier, embed glucose oxidase and heparin in the electrode, Dry in the oven; 3, the excess (n NCO :n NH2 / OH / SH The value is controlled at 1.5) of isophorone diisocyanate (IPDI) reacts with polyether diol and polysiloxane, and adds a small amount of 1,4-butanediol to generate polyurethane prepolymer, and the reaction time is 6 hours, the reaction temperature is 65°C, and after the reaction, it is purified by liquid phase preparative chromatography. The prepolymer is modified on the enzyme layer by brushing, and then cured by ultraviolet light to form a film. The prepared biosensing layer has good adhesion. It does not fall off in animal or human long-term tests, and has good biocompatibility and anti-protein adsorption performance.

[0051] According to the bioenzyme sensor that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com