Variable-chamber-containing box filter plate of box filter press

A box-type filter press, a variable technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of reducing water content, the pressure difference of the filter plate 4 cannot be too high, and cannot be realized, so as to ensure The effect of filtering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

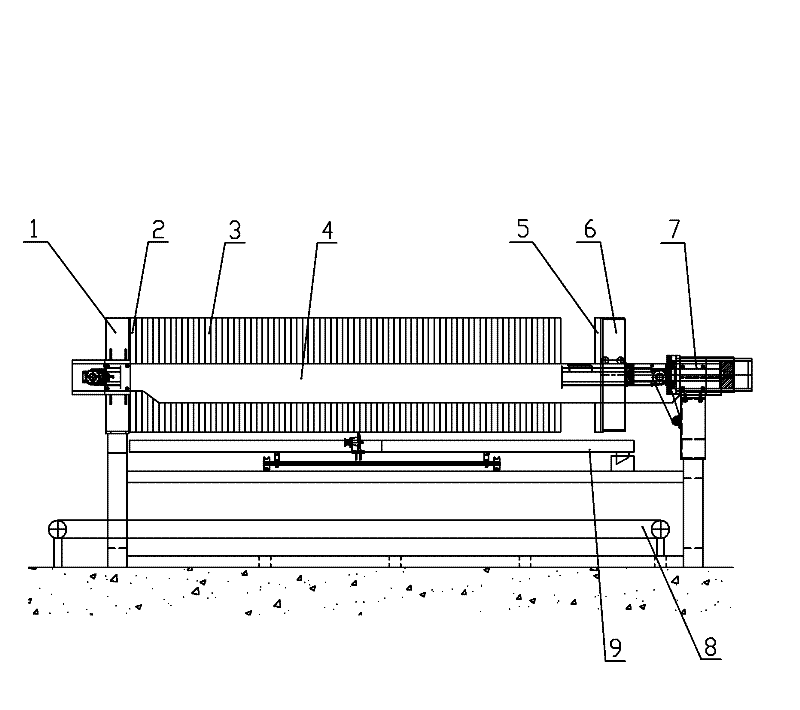

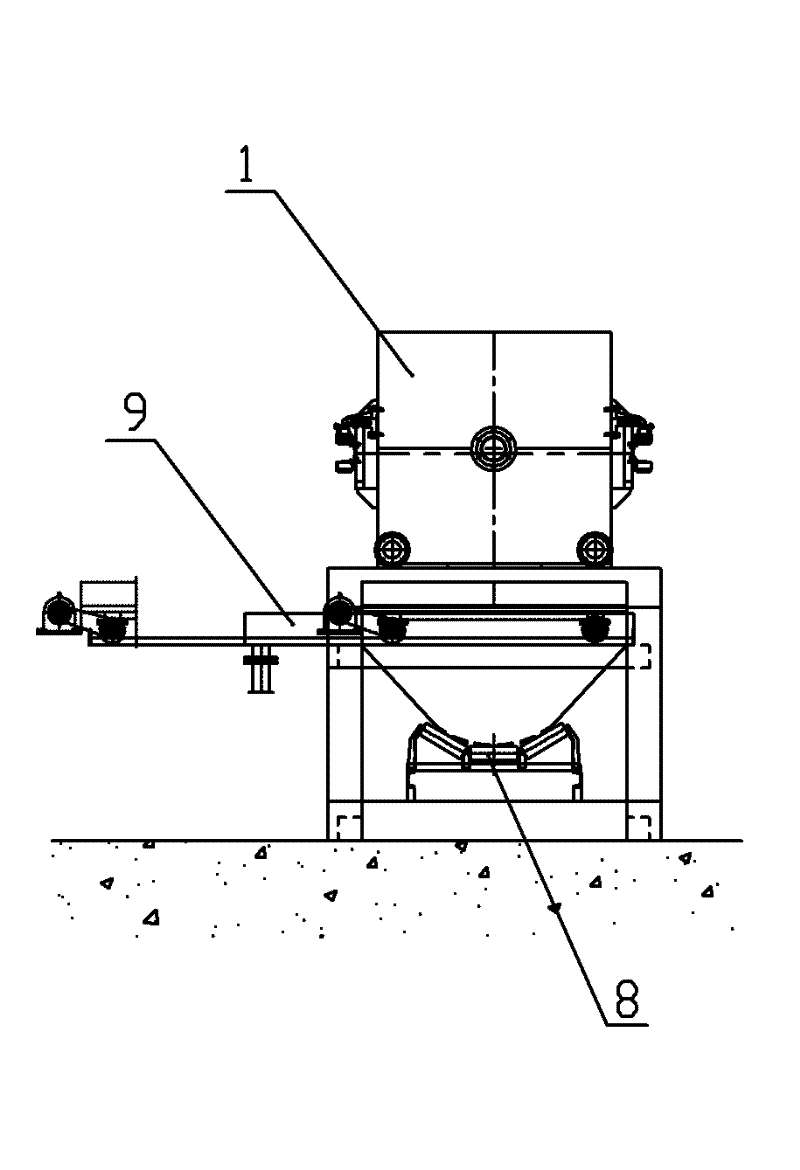

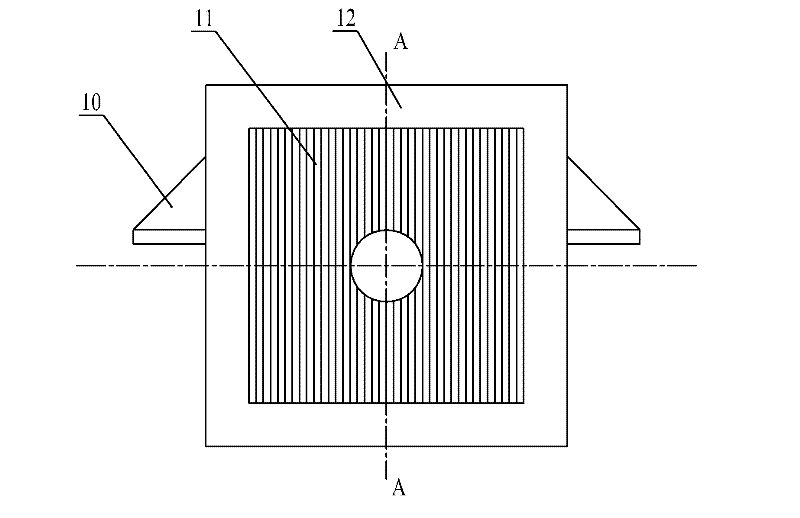

[0018] Such as figure 1 , figure 2 As shown: the variable chamber box filter plate of the box filter press is mainly composed of an outer water permeable plate 11, a pressure bearing plate 12, an inner water permeable plate 13, a positioning pin 14, an elastic member 15 and a pressure plate 16. The pressure plate 12 corresponds to the shape and size of the pressure plate 16 and is equipped with a positioning pin 14. The function of the positioning pin 14 is to enable the pressure plate 12 and the pressure plate 16 to move relative to each other but not to rotate relative to each other; An inner cavity and an outer cavity are provided respectively, the inner permeable plate 13 is assembled in the inner cavity, an elastic member 15 is sandwiched between the inner permeable plate 13 and the pressure plate 16, and the outer permeable plate 11 is assembled in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com